產(chǎn)品中心

美國強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國麥克福斯

卡特彼勒柴油發(fā)動機(jī)參數(shù)

沃爾沃發(fā)動機(jī)全系參數(shù)

英國珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動機(jī)零件查詢圖冊

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國道依茨 韓國大宇柴油發(fā)動機(jī)配件

康明斯全系列柴油發(fā)動機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動機(jī)配件中心

珀金斯Perkins1103D-33(T)(TA)測試調(diào)整(英文)

詳細(xì)描述

Systems Operation

Testing and Adjusting

1103D Industrial Engine

XK (Engine)

XL (Engine)

XM (Engine)

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

Important Safety Information

Most accidents tha t involve produc t op eration, ma intena nc e and repair are caus ed by failure to

ob serve basic safety rules or precautions . An accident can often be avoided by recog nizing pote ntially

ha za rdous situations before an accident oc curs . A person mus t be alert to pote ntial ha za rds. This

person should also ha ve the ne cessary training, skills and tools to perform the se func tions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Sa fety precautions and warning s are provided in this ma nua l and on the produc t. If the se ha za rd

warning s are not he eded, bod ily injury or death could oc cur to you or to othe r persons .

The ha za rds are identified by the “Safety Alert Symb ol” and followed by a “Signa l Word” suc h as

“DANGER”, “WARNING” or “CAUTION”. The Sa fety Alert “WARNING” label is shown below.

The me aning of this safety alert symb ol is as follows:

Attention! Become Alert! Your Safety is Involved.

The me ssage tha t appears und er the warning explains the ha za rd and can be either written or

pictorially presente d.

Op erations tha t ma y caus e produc t dama ge are identified by “NOTICE” labels on the produc t and in

this pub lication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The informa tion, specifications , and illustrations in this pub lication are on the basis of informa tion tha t

was available at the time tha t the pub lication was written. The specifications , torque s, pressure s,

me asure me nts , adjustme nts , illustrations , and othe r items can cha ng e at any time. These cha ng es can

affect the service tha t is given to the produc t. Ob tain the comp lete and mos t current informa tion before

you start any job. Pe rkins dealers or Pe rkins distributors ha ve the mos t current informa tion available.

When replacement parts are required for this

product Perkins recommends using Perkins

replacement parts.

Failure to heed this warning can lead to prema-

ture failures, product damage, personal injury or

death.

This document has been printed from SPI². Not for Resale

![]()

![]()

KENR6912

3

Table of Contents

Table of Contents

Electrical System

Alternator - Test .................................................... 44

Battery - Test ......................................................... 44

Electric Starting System - Test .............................. 45

Glow Plugs - Test .................................................. 47

V-Belt - Test .......................................................... 47

Systems Operation Section

Engine Design ....................................................... 4

General Information ................................................ 4

Fuel System ........................................................... 7

Air Inlet and Exhaust System ................................. 9

Lubrication System .............................................. 13

Cooling System .................................................... 15

Basic Engine ......................................................... 15

Electrical System ................................................. 16

Index Section

Index ..................................................................... 49

Testing and Adjusting Section

Fuel System

Fuel System - Inspect ........................................... 18

Air in Fuel - Test .................................................... 18

Finding Top Center Position for No. 1 Piston ........ 19

Fuel Injection Pump Timing - Check ..................... 20

Fuel Injection Pump Timing - Adjust ..................... 20

Fuel Quality - Test ................................................. 20

Fuel System - Prime ............................................. 21

Fuel System Pressure - Test ................................. 21

Air Inlet and Exhaust System

Air Inlet and Exhaust System - Inspect ................. 23

Wastegate - Test ................................................... 23

Exhaust Temperature - Test .................................. 24

Engine Crankcase Pressure (Blowby) - Test ........ 24

Compression - Test ............................................... 24

Engine Valve Lash - Inspect/Adjust ...................... 25

Valve Depth - Inspect ............................................ 27

Valve Guide - Inspect ............................................ 27

Lubrication System

Engine Oil Pressure - Test .................................... 29

Engine Oil Pump - Inspect .................................... 29

Excessive Bearing Wear - Inspect ........................ 30

Excessive Engine Oil Consumption - Inspect ....... 30

Increased Engine Oil Temperature - Inspect ........ 31

Cooling System

Cooling System - Check (Overheating) ................ 32

Cooling System - Inspect ...................................... 33

Cooling System - Test ........................................... 33

Engine Oil Cooler - Inspect ................................... 35

Water Temperature Regulator - Test ..................... 36

Basic Engine

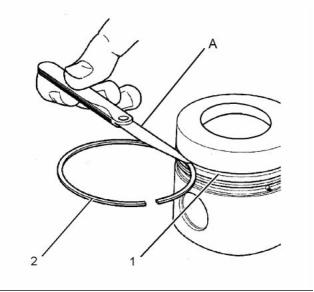

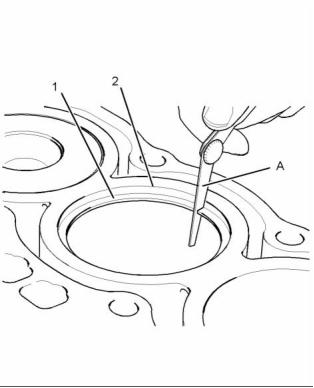

Piston Ring Groove - Inspect ................................ 37

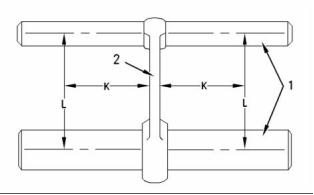

Connecting Rod - Inspect ..................................... 38

Connecting Rod Bearings - Inspect ...................... 38

Main Bearings - Inspect ........................................ 38

Cylinder Block - Inspect ........................................ 38

Cylinder Head - Inspect ........................................ 39

Piston Height - Inspect .......................................... 40

Flywheel - Inspect ................................................. 40

Flywheel Housing - Inspect ................................... 41

Gear Group - Inspect ............................................ 43

This document has been printed from SPI². Not for Resale

![]()

4

Systems Operation Section

KENR6912

Systems Operation Section

The front of the engine is opposite the flywheel end

of the engine. The left side of the engine and the right

side of the engine are determined from the flywheel

end. Number 1 cylinder is the front cylinder of the

engine.

i02873613

Engine Design

i02873620

General Information

Engine Description

Note: When you are ordering new parts, refer to the

engine identification number in order to receive the

correct parts. Refer to Operation and Maintenance

Manual, “Product Identification Information” for the

correct numbers for your engine.

The engine cylinders are arranged in-line. The

engines are controlled by a mechanically governed

fuel injection pump.

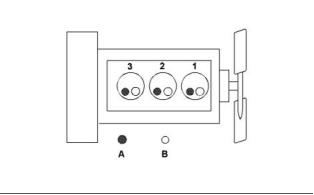

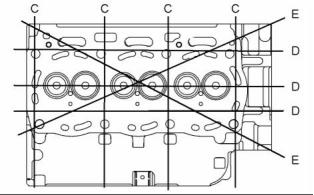

g01223241

Illustration 1

(A) Exhaust valve

(B) Inlet valve

The cylinder head assembly has one inlet valve and

one exhaust valve for each cylinder. Each valve has

one valve spring. The pistons have two compression

rings and an oil control ring.

1103D Industrial Engine Specification

Type .......................... Three cylinder and four stroke

Type of combustion ............................ Direct injection

Bore ......................................... 105 mm (4.133 inch)

Stroke ........................................ 127 mm (5.00 inch)

It is important to ensure the correct piston height so

that the piston does not contact the cylinder head.

The correct piston height also ensures the efficient

combustion of fuel.

The 1103D engine crankshaft has four main journals.

End play is controlled by thrust washers that are

located on both sides of the number three main

bearing.

Displacement ...................................... 3.3 L (201 in )

3

Compression ratio

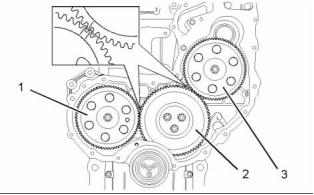

The timing case has a hole that corresponds with a

hole in the crankshaft. Use an alignment pin to find

top center (TC). The camshaft gear has a timing

hole that corresponds with a timing hole in the timing

case. The timing holes ensure that the camshaft and

the crankshaft are in time with each other.

Naturally aspirated ........................................ 19.25:1

Turbocharged ................................................ 18.23:1

Turbocharged aftercooled ............................... 18.2:1

Number of cylinders ................................................ 3

Cylinder arrangement ..................................... In-line

Firing order ..................................................... 1, 2, 3

The crankshaft gear rotates the idler gear. The idler

gear rotates the camshaft gear and the fuel injection

pump gear. The idler gear for the engine oil pump is

rotated by the crankshaft gear. This idler rotates the

engine oil pump.

When the crankshaft is viewed from the front of

the engine, the crankshaft rotates in the following

direction. ................................................... Clockwise

The fuel injection pump is a gear-driven pump that

is mounted to the back of the front housing. The

fuel transfer pump is electrically operated. The fuel

transfer pump has an integral fuel filter. The fuel

transfer pump is usually located on the left hand side

of the cylinder block. Some applications may have

the fuel transfer pump and the water separator (if

equipped) relocated off the engine.

This document has been printed from SPI². Not for Resale

![]()

![]()

KENR6912

5

Systems Operation Section

The oil pump is driven by an idler gear. The engine

oil pump sends lubricating oil to the main oil gallery.

The oil relief valve is internal to the oil pump.

Coolant from the bottom of the radiator passes

through the water pump. The water pump is driven

by the Fuel injection pump gear.

Lifting the Engine

NOTICE

Failure to follow recommended procedures for han-

dling or transporting engines can lead to engine dam-

age.

To avoid possible engine damage, use the following

procedure.

When you are lifting or moving the engine, use the

following procedures in order to prevent engine

damage.

1. Do not tilt the engine to an extreme angle unless

the lubricating oil is first drained from the oil pan.

2. Do not turn the engine onto a side or an end

surface unless the lubricating oil is first drained

from the oil pan.

3. If the oil is not drained prior to tilting the engine or

turning the engine onto a side or an end surface,

the lubricating oil from the oil pan can flow into

the intake manifold and the cylinder bores. This

situation could cause a hydraulic lock in the

engine. Hydraulic lock can severely damage the

engine.

4. The engine oil should be refilled to the correct

level before the engine is started.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

6

Systems Operation Section

KENR6912

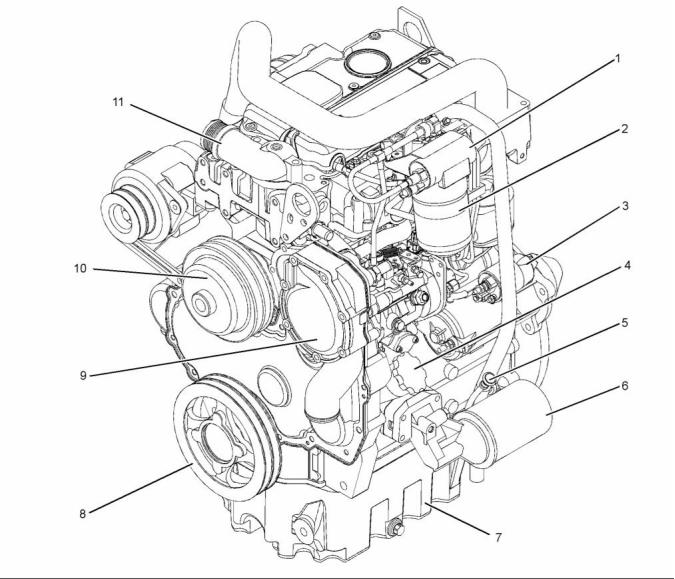

1103D Engine Model Views

g01399674

Illustration 2

Typical example

(1) Fuel transfer pump

(2) Fuel filter

(5) Dipstick

(6) Oil filter

(9) Water pump

(10) Fan pulley

(3) Starting motor

(4) Oil filler cap

(7) Oil pan

(8) Crankshaft pulley

(11) Water temperature regulator housing

This document has been printed from SPI². Not for Resale

![]()

![]()

KENR6912

7

Systems Operation Section

g01403711

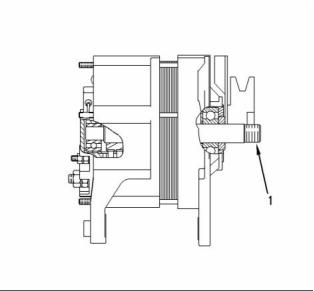

Illustration 3

Typical example

(1) Alternator

(2) Turbocharger

(3) Turbocharger oil supply

(4) Turbocharger oil drain

(5) Exhaust manifold

The fuel transfer pump draws fuel from the fuel tank

and through the water separator. When the fuel goes

through the water separator, any water in the fuel will

go to the bottom of the bowl. The fuel transfer pump

sends the fuel at a low pressure to the fuel filter. From

the fuel filter, the fuel goes through the supply line to

the fuel injection pump.

i02873638

Fuel System

The Delphi DP210 fuel injection pump is installed

on the naturally aspirated 1103D engine. The

Delphi DP310 fuel injection pump is installed on the

turbocharged 1103D engine.

This document has been printed from SPI². Not for Resale

![]()

![]()

8

Systems Operation Section

KENR6912

The fuel injection pump sends fuel through the high

pressure fuel lines to each of the fuel injectors. The

fuel injector sprays the fuel into the cylinder. Fuel that

is not injected flows through the fuel return line to the

top of the fuel filter, back to the fuel tank.

Cold Start Advance Unit

The cold start advance unit holds the timing of the

fuel injection pump in an advance position when the

engine is cold.

The engine must not be started until the fuel injection

pump is full of fuel that is free of air. The fuel injection

pump requires fuel for lubrication. The precision parts

of the pump are easily damaged without lubrication.

The coolant switch for the cold start advance unit is

on the water temperature regulator housing on the

left side of the engine.

When the engine is cold, the sender unit is

energized in order to advance the fuel injection

pump timing for the cold start operation. When the

correct temperature is achieved the sender unit is

de-energized and the fuel injection pump timing is

returned to the normal operating position.

The fuel system must be primed when any of the

following conditions occur:

• The fuel filter is changed.

• The fuel line is removed.

If the switch fails in the closed position, the engine

will run with advanced fuel injection timing. The

engine will have higher cylinder pressure and engine

damage may result.

• The fuel injection pump is removed.

Fuel System Components

If the switch fails in the open position the engine

will run with the fuel injection timing in the normal

operating position. The engine will be more difficult

to start. When the engine is cold the engine might

emit white smoke.

Fuel Injection Pump

General Operation

The fuel injection pump is a pressurized system

that is totally enclosed. The pump sends the correct

amount of fuel under high pressure at the correct time

through the fuel injectors to the individual cylinders.

The fuel injection pump regulates the amount of fuel

that is delivered to the fuel injectors. This action

controls the engine rpm by the governor setting or

the position of the throttle control.

The fuel lines to the fuel injectors are equal lengths.

This ensures even pressure and correct injection

timing at each fuel injector.

During operation, extra fuel is used as coolant and

lubricant for moving parts of the pump. The extra fuel

is circulated through the pump housing. The extra

fuel is then returned to the fuel tank.

The Delphi DP210 and DP310 fuel injection pumps

must be serviced by an authorized Delphi technician.

For repair information, contact your Perkins

distributor.

High idle and low idle of the fuel injection pump are

factory set. Idle adjustments can not be made to the

fuel pump. The Delphi DP310 fuel injection pump has

a boost control. The Delphi DP210 and DP310 fuel

injection pumps have an engine stop solenoid and a

feature that vents air from the pump.

The Delphi DP210 and DP310 fuel injection pumps

have a cold starting aid. The cold starting aid

advances the timing of the pump when the engine is

cold. The cold starting aid is electrically operated.

This document has been printed from SPI². Not for Resale

![]()

KENR6912

9

Systems Operation Section

i02797476

Air Inlet and Exhaust System

Turbocharged Engines

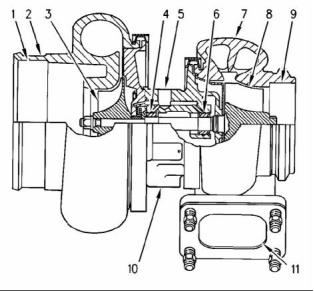

g01237037

Illustration 4

Air inlet and exhaust system

(1) Exhaust manifold

(2) Fuel injection nozzle

(3) Glow plug

(5) Exhaust outlet

(9) Inlet valve

(10) Engine cylinder

(11) Exhaust valve

(6) Turbocharger turbine wheel

(7) Turbocharger compressor wheel

(8) Air inlet

(4) Inlet manifold

The components of the air inlet and exhaust system

control the quality of air and the amount of air that is

available for combustion. The air inlet and exhaust

system consists of the following components:

Air is forced into the inlet manifold (4). Air flow from

the inlet manifold to the engine cylinders (10) is

controlled by the inlet valves (9). There is one inlet

valve and one exhaust valve (11) for each cylinder.

The inlet valve opens when the piston moves down

on the intake stroke. When the inlet valve opens,

compressed air from the inlet port is forced into the

cylinder. The complete cycle consists of four strokes:

• Air cleaner

• Turbocharger

• Inlet manifold that is integral with the cylinder head

• Cylinder head, injectors and glow plugs

• Valves and valve system components

• Piston and cylinder

• Inlet

• Compression

• Power

• Exhaust

• Exhaust manifold

On the compression stroke, the piston moves back

up the cylinder and the inlet valve (9) closes. The

air is compressed and this compression generates

more heat.

Air is drawn in through the air cleaner into the air

inlet of the turbocharger (8) by the turbocharger

compressor wheel (7). The air is compressed and

heated.

Note: If the cold starting system is operating, the

glow plugs (3) will also heat the air in the cylinder.

This document has been printed from SPI². Not for Resale

![]()

![]()

10

KENR6912

Systems Operation Section

Just before the piston reaches the TC position, fuel is

injected into the cylinder via the fuel injection nozzle

(2). The air/fuel mixture ignites. The ignition of the

gases initiates the power stroke. Both the inlet and

the exhaust valves are closed and the expanding

gases force the piston downward toward the bottom

center (BC) position .

From the BC position, the piston moves upward. This

initiates the exhaust stroke. The exhaust valve (11)

opens. The exhaust gases are forced through the

open exhaust valve into the exhaust manifold (1).

Exhaust gases from exhaust manifold (1) enter the

turbine side of the turbocharger in order to turn

turbocharger turbine wheel (6). The turbocharger

turbine wheel is connected to the shaft that drives the

turbocharger compressor wheel (7). Exhaust gases

from the turbocharger, pass through the exhaust

outlet (5), and an exhaust pipe and a silencer.

Naturally Aspirated Engines

g01237212

Illustration 5

Air inlet and exhaust system

(1) Exhaust manifold

(2) Fuel injection nozzle

(3) Glow plug

(4) Inlet manifold

(5) Exhaust outlet

(6) Air inlet

(7) Inlet valve

(8) Engine cylinder

(9) Exhaust valve

The components of the air inlet and exhaust system

control the quality of air and the amount of air that is

available for combustion. The air inlet and exhaust

system consists of the following components:

• Valves and valve system components

• Piston and cylinder

• Exhaust manifold

• Air cleaner

• Inlet manifold

• Cylinder head, injectors and glow plugs

This document has been printed from SPI². Not for Resale

![]()

![]()

KENR6912

11

Systems Operation Section

Air is drawn in through the air cleaner into the air inlet

(6) of the inlet manifold (4). Air flow from the inlet

manifold to the engine cylinders (8) is controlled by

the inlet valves (7). There is one inlet valve and one

exhaust valve (9) for each cylinder. The inlet valve

opens when the piston moves down on the intake

stroke. When the inlet valve opens, air from the inlet

port is forced into the cylinder. The complete cycle

consists of four strokes:

• Engine torque is increased.

• Durability of the engine is improved.

• Emissions from the engine are reduced.

• Inlet

• Compression

• Power

• Exhaust

On the compression stroke, the piston moves back

up the cylinder and the inlet valve (7) closes. The

air is compressed and this compression generates

more heat.

Note: If the cold starting system is operating, the

glow plugs (3) will also heat the air in the cylinder.

Just before the piston reaches the TC position, fuel is

injected into the cylinder via the fuel injection nozzle

(2). The air/fuel mixture ignites. The ignition of the

gases initiates the power stroke. Both the inlet and

the exhaust valves are closed and the expanding

gases force the piston downward toward the bottom

center (BC) position .

g01263770

Illustration 6

Typical example

Components of a turbocharger (typical example)

(1) Air inlet

(2) Compressor housing

(3) Turbocharger compressor wheel

(4) Bearing

(5) Oil inlet port

(6) Bearing

From the BC position, the piston moves upward. This

initiates the exhaust stroke. The exhaust valve (9)

opens. The exhaust gases are forced through the

open exhaust valve into the exhaust manifold (1).

(7) Turbine housing

(8) Turbocharger turbine wheel

(9) Exhaust outlet

(10) Oil outlet port

(11) Exhaust inlet

Exhaust gases from exhaust manifold (1), pass

through exhaust outlet (5), and an exhaust pipe and

a silencer.

A turbocharger is installed between the exhaust and

inlet manifolds. The turbocharger is driven by exhaust

gases which flow through the exhaust inlet (11). The

energy of the exhaust gas turns the turbine wheel

(8). Then, the exhaust gas flows out of the turbine

housing (7) through the exhaust outlet (9).

Turbocharger

Note: The turbocharger is not serviceable.

The turbocharger turbine wheel and the turbocharger

compressor wheel (3) are installed on the same shaft.

Therefore, the turbocharger turbine wheel and the

turbocharger compressor wheel rotate at the same

rpm. The turbocharger compressor wheel is enclosed

by the compressor housing (2). The turbocharger

compressor wheel compresses the air that is drawn

in from the air intake (1). The air flows into the engine

cylinders through the inlet valves of the cylinders.

A turbocharger increases the temperature and the

density of the air that is sent to the engine cylinder.

This condition causes a lower temperature of ignition

to develop earlier in the compression stroke. The

compression stroke is also timed in a more accurate

way with the fuel injection. Surplus air lowers the

temperature of combustion. This surplus air also

provides internal cooling.

A turbocharger improves the following aspects of

engine performance:

The oil from the main gallery of the cylinder block

flows through the oil inlet port (5) in order to

lubricate the turbocharger bearings (4) and (6). The

pressurized oil passes through the bearing housing

of the turbocharger. The oil is returned through the oil

outlet port (10) to the oil pan.

• Power output is increased.

• Fuel efficiency is improved.

This document has been printed from SPI². Not for Resale

![]()

![]()

12

KENR6912

Systems Operation Section

The turbocharger has a wastegate. The wastegate is

controlled by the boost pressure. This allows some

of the exhaust to bypass the turbocharger at higher

engine speeds. The wastegate is a type of valve

that automatically opens at a preset level of boost

pressure in order to allow exhaust gas to flow around

the turbine. The wastegate allows the design of the

turbocharger to be more effective at lower engine

speeds.

The wastegate is controlled by a diaphragm. One

side of this diaphragm is open to the atmosphere.

The other side of this diaphragm is open to the

manifold pressure.

Cylinder Head And Valves

The valves and the valve mechanism control the

flow of the air and the exhaust gases in the cylinder

during engine operation. The cylinder head assembly

has two valves for each cylinder. Each valve has one

valve spring. The ports for the inlet valves are on

the left side of the cylinder head. The ports for the

exhaust valves are on the right side of the cylinder

head. Steel valve seat inserts are installed in the

cylinder head for both the inlet and the exhaust

valves. The valve seat inserts can be replaced.

The valves are installed in valve guides. The valve

guides can be replaced. The stem of the exhaust

valve is shaped in order to prevent the seizure of the

valve. The seizure of a valve can be caused by a

buildup of carbon under the head of the valve.

The inlet and the exhaust valves are opened and

closed by the rotation and movement of the following

components:

• Crankshaft

• Camshaft

• Valve lifters

• Pushrods

• Rocker arms

• Valve springs

The camshaft gear is driven by the crankshaft gear.

The camshaft and the crankshaft are timed together.

When the camshaft turns, the valve lifters and the

pushrods are moved up and down. The pushrods

move the rocker arms. The movement of the rocker

arms open the valves. The opening and closing of

the valves is timed with the firing sequence of the

engine. The valve springs push the valves back to

the closed position.

This document has been printed from SPI². Not for Resale

![]()

KENR6912

13

Systems Operation Section

i02876572

Lubrication System

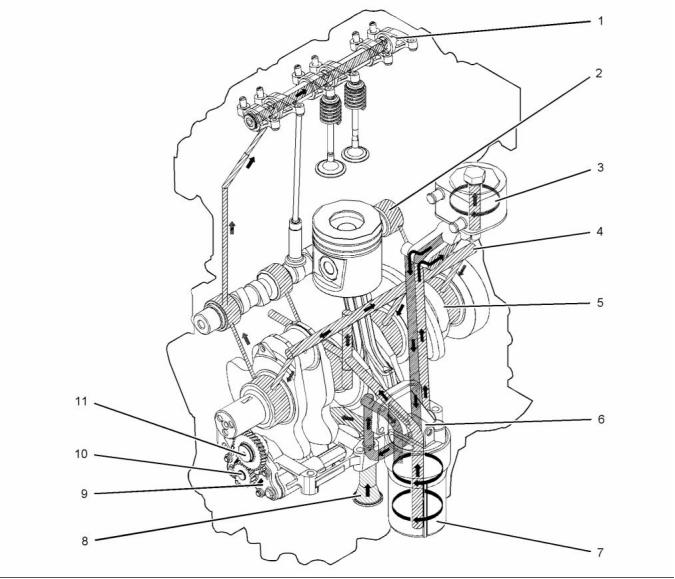

g01399859

Illustration 7

Flow diagram of the lubrication system for the 1103D engine

(1) Rocker shaft

(2) Camshaft journal

(3) Oil cooler

(5) Rod bearing journal

(6) Filter head

(7) Oil filter

(9) Oil pump

(10) Oil pump gear

(11) Lower idler gear

(4) Oil passage

(8) Oil strainer

Lubricating oil from the oil pan flows through a

strainer and a pipe (8) to the suction side of the

engine oil pump (9). Pressure for the lubrication

system is supplied by the oil pump. The crankshaft

gear drives the lower idler gear (12). The lower idler

gear (11) drives the oil pump gear (10). The pump

has an inner rotor and an outer rotor. The axis of

rotation of the rotors are off-center relative to each

other. There is an interference fit between the inner

rotor and the drive shaft.

The inner rotor has five lobes which mesh with the six

lobes of the outer rotor. When the pump rotates, the

distance increases between the lobes of the outer

rotor and the lobes of the inner rotor in order to create

suction. When the distance decreases between the

lobes, pressure is created.

This document has been printed from SPI². Not for Resale

![]()

![]()

14

KENR6912

Systems Operation Section

The lubricating oil flows from the outlet side of the oil

pump (9) through a passage to the oil filter head (6).

The oil then flows from the oil filter head through a

passage to a oil cooler (3). The oil cooler is located

on the left side of the cylinder block.

From the oil cooler, the oil returns through a passage

to the oil filter head. The oil then flows through a

bypass valve that permits the lubrication system

to function if the oil filter becomes blocked. Under

normal conditions, the oil then flows to the oil filter (7).

The oil flows from the oil filter through a passage that

is drilled across the cylinder block to the oil gallery

(4). The oil gallery is drilled through the total length

of the left side of the cylinder block. If the oil filter is

on the right side of the engine, the oil flows through

a passage that is drilled across the cylinder block to

the pressure gallery.

Lubricating oil from the oil gallery flows through

high pressure passages to the main bearings of the

crankshaft . Then, the oil flows through the passages

in the crankshaft to the connecting rod bearing

journals (5). The pistons and the cylinder bores are

lubricated by the splash of oil and the oil mist.

Lubricating oil from the main bearings flows through

passages in the cylinder block to the journals of the

camshaft. Then, the oil flows from the second journal

of the camshaft (2) at a reduced pressure to the

cylinder head. The oil then flows through the center

of the rocker shaft (1) to the rocker arm levers. The

valve stems, the valve springs and the valve lifters

are lubricated by the splash and the oil mist.

The hub of the idler gear is lubricated by oil from the

oil gallery. The timing gears are lubricated by the

splash from the oil.

An external line from the cylinder block supplies oil to

the turbocharger. The oil then flows through a return

line to the oil pan.

Engines have piston cooling jets that are supplied

with oil from the oil gallery. The piston cooling jets

spray lubricating oil on the underside of the pistons in

order to cool the pistons.

This document has been printed from SPI². Not for Resale

![]()

KENR6912

15

Systems Operation Section

i02873641

Cooling System

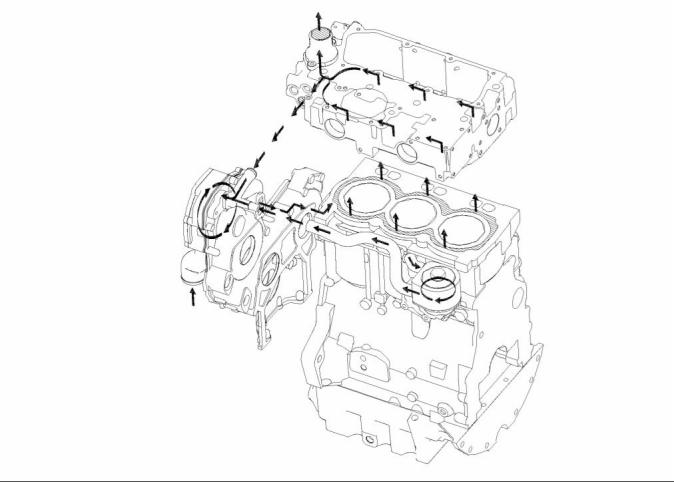

g01016432

Illustration 8

Flow diagram of the cooling system for the 1103D engine

The coolant flows from the bottom of the radiator to

the centrifugal water pump. The water pump assists

in the flow of the coolant through the system. The

water pump is installed on the front of the timing

case. The water pump is gear-driven by the fuel

injection pump gear.

From the rear of the cylinder block, some of the

coolant passes into the oil cooler (if equipped). The

oil cooler is located on the left side of the cylinder

block. The coolant passes through the oil cooler

before being returned through an external line to the

inlet side of the water pump.

The water pump forces the coolant through a

passage in the front of the timing case to the water

jacket in the top left side of the cylinder block. The

coolant continues to the rear of the cylinder block.

i02873644

Basic Engine

The main flow of the coolant passes from the rear of

the cylinder block into the rear of the cylinder head.

The coolant flows forward through the cylinder head

and into the water temperature regulator housing. If

the water temperature regulator is closed, the coolant

goes directly through a bypass to the inlet side of

the water pump. If the water temperature regulator

is open, the bypass is closed and the coolant flows

to the top of the radiator.

Cylinder Block and Cylinder Head

The cylinder block for the 1103D engine has three

cylinders which are arranged in-line.

This document has been printed from SPI². Not for Resale

![]()

![]()

16

KENR6912

Systems Operation Section

Crankshaft

The cylinder block for the 1103D engine has four

main bearings which support the crankshaft. Thrust

washers on both sides of the number three main

bearing control the end play of the crankshaft.

The crankshaft changes the linear energy of the

pistons and connecting rods into rotary torque in

order to power external equipment.

A cylinder head gasket is used between the

engine block and the cylinder head in order to seal

combustion gases, water, and oil.

A gear at the front of the crankshaft drives the timing

gears. The crankshaft gear turns the idler gear which

then turns the following gears:

The engine has a cast iron cylinder head. The inlet

manifold is integral within the cylinder head. An inlet

valve and an exhaust valve for each cylinder are

controlled by a pushrod valve system. The ports for

the inlet valves are on the left side of the cylinder

head. The ports for the exhaust valves are on the

right side of the cylinder head.

• Camshaft gear

• Fuel injection pump

• Lower idler gear which turns the gear of the

lubricating oil pump

Pistons, Rings, and Connecting

Rods

Camshaft

The engine has a single camshaft. The camshaft

is driven by an idler gear in the front housing. The

camshaft uses only one bearing on the front journal.

The other journals rotate in the bore of the cylinder

block. The front bearing and the camshaft bores

in the cylinder block support the camshaft. As the

camshaft turns, the camshaft lobes move the valve

system components. The valve system components

move the inlet and exhaust valves in each cylinder.

The camshaft gear must be timed to the crankshaft

gear. The relationship between the lobes and the

camshaft gear causes the valves in each cylinder to

be opened and closed at the correct time.

The pistons have a combustion chamber in the top of

the piston in order to provide an efficient mix of fuel

and air. The piston pin is off-center in order to reduce

the noise level.

The pistons have two compression rings and an oil

control ring. The groove for the top ring has a hard

metal insert in order to reduce wear of the groove.

The skirt has a layer of graphite in order to reduce

wear.

The correct piston height is important in order to

ensure that the piston does not contact the cylinder

head. The correct piston height also ensures the

efficient combustion of fuel which is necessary in

order to conform to requirements for emissions.

i02797480

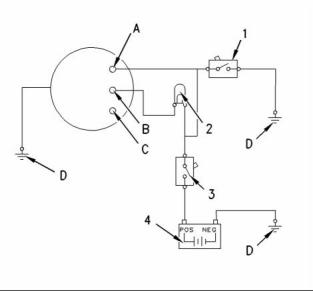

Electrical System

Engines are equipped with connecting rods that have

bearing caps that are fracture split. The bearing caps

on fracture split connecting rods are retained with

torx screws. Connecting rods with bearing caps that

are fracture split have the following characteristics:

The electrical system is a negative ground system.

The charging circuit operates when the engine

is running. The alternator in the charging circuit

produces direct current for the electrical system.

• Higher integrity for the rod

• The splitting produces an accurately matched

surface on each side for improved strength.

• Modern design

The connecting rod is matched to each cylinder.

The piston height is controlled by the length of the

connecting rod. Six different lengths of connecting

rods are available in order to attain the correct piston

height.

This document has been printed from SPI². Not for Resale

![]()

KENR6912

17

Systems Operation Section

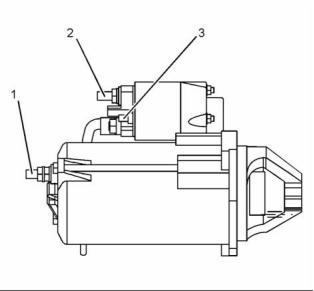

Starting Motor

Alternator

g00303424

g01216877

Illustration 10

Illustration 9

(1) Typical view of a shaft for mounting the pulley

Typical view of a 12 Volt Starting Motor

(1) Terminal for connection of the ground cable

(2) Terminal 30 for connection of the battery cable

(3) Terminal 50 for connection of the ignition switch

The alternator produces the following electrical

output:

• Three-phase

• Full-wave

• Rectified

The starting motor turns the engine flywheel. The

rpm is high enough in order to initiate a sustained

operation of the fuel ignition in the cylinders.

The starting motor has a solenoid. When the ignition

switch is activated, voltage from the electrical system

will cause the solenoid to engage the pinion in the

flywheel ring gear of the engine. When the pinion

gear is engaged in the flywheel ring gear, the

electrical contacts in the solenoid close the circuit

between the battery and the starting motor.

The alternator is an electro-mechanical component.

The alternator is driven by a drive belt from the

crankshaft pulley. The alternator charges the storage

battery during the engine operation.

The alternator converts the mechanical energy

and the magnetic energy into electrical energy.

This conversion is done by rotating a direct current

electromagnetic field on the inside of a three-phase

stator. The electromagnetic field is generated by

electrical current flowing through a rotor. The stator

generates AC electrical power.

When the engine begins to run, the overrunning

clutch of the pinion drive prevents damage to the

armature. Damage to the armature is caused by

excessive speeds. The clutch prevents damage by

stopping the mechanical connection. However, the

pinion will stay meshed with the ring gear until the

ignition switch is released. A spring in the overrunning

clutch returns the clutch to the rest position.

The alternating current is changed to direct current

by a three-phase, full-wave rectifier. Direct current

flows to the output terminal of the alternator. The

rectifier has three exciter diodes. The direct current

is used for the charging process.

A regulator is installed on the rear end of the

alternator. Two brushes conduct current through two

slip rings. The current then flows to the rotor field. A

capacitor protects the rectifier from high voltages.

The alternator is connected to the battery through

the ignition switch. Therefore, alternator excitation

occurs when the switch is in the ON position.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

18

KENR6912

Testing and Adjusting Section

Testing and Adjusting

Section

2. Install a suitable sight gauge in the fuel return line.

When possible, install the sight gauge in a straight

section of the fuel line that is at least 304.8 mm

(12 inches) long. Do not install the sight gauge

near the following devices that create turbulence:

Fuel System

• Elbows

• Relief valves

• Check valves

i02797486

Fuel System - Inspect

Observe the fuel flow during engine cranking.

Look for air bubbles in the fuel. If there is no fuel

that is present in the sight gauge, prime the fuel

system. Refer to Systems Operation, Testing

and Adjusting, “Fuel System - Prime” for more

information. If the engine starts, check for air in

the fuel at varying engine speeds. When possible,

operate the engine under the conditions which

have been suspect.

A fault with the components that send fuel to the

engine can cause low fuel pressure. This can

decrease engine performance.

1. Check the fuel level in the fuel tank. , Ensure that

the vent in the fuel cap is not filled with dirt.

2. Check all fuel lines for fuel leakage. The fuel lines

must be free from restrictions and faulty bends.

Verify that the fuel return line is not collapsed.

3. Inspect the fuel filter for excess contamination. If

necessary, install a new fuel filter. Determine the

source of the contamination. Make the necessary

repairs.

4. Service the primary fuel filter (if equipped).

5. Remove any air that may be in the fuel system.

Refer to Systems Operation, Testing and

Adjusting, “Fuel System - Prime”.

i02873659

Air in Fuel - Test

g00578151

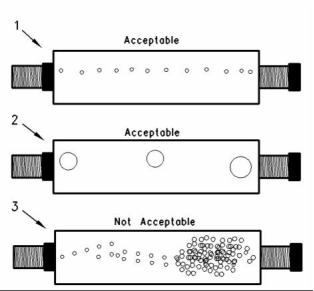

Illustration 11

This procedure checks for air in the fuel system. This

procedure also assists in finding the source of the air.

Sight Gauge

(1) A steady stream of small bubbles with a diameter of

approximately 1.60 mm (0.063 inch) is an acceptable amount

of air in the fuel.

(2) Bubbles with a diameter of approximately 6.35 mm (0.250 inch)

are also acceptable if there is two seconds to three seconds

intervals between bubbles.

1. Examine the fuel system for leaks. Ensure that

the fuel line fittings are properly tightened. Check

the fuel level in the fuel tank. Air can enter the

fuel system on the suction side between the fuel

transfer pump and the fuel tank.

(3) Excessive air bubbles in the fuel are not acceptable.

Work carefully around an engine that is running.

Engine parts that are hot, or parts that are moving,

can cause personal injury.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

KENR6912

19

Testing and Adjusting Section

3. If excessive air is seen in the sight gauge in the

fuel return line, install a second sight gauge at the

inlet to the fuel transfer pump. If a second sight

gauge is not available, move the sight gauge from

the fuel return line and install the sight gauge at

the inlet to the fuel transfer pump. Observe the fuel

flow during engine cranking. Look for air bubbles

in the fuel. If there is no fuel that is present in

the sight gauge, prime the fuel system. Refer

to Systems Operation, Testing and Adjusting,

“Fuel System - Prime” for more information. If the

engine starts, check for air in the fuel at varying

engine speeds.

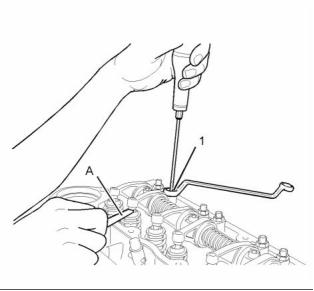

i02873757

Finding Top Center Position

for No. 1 Piston

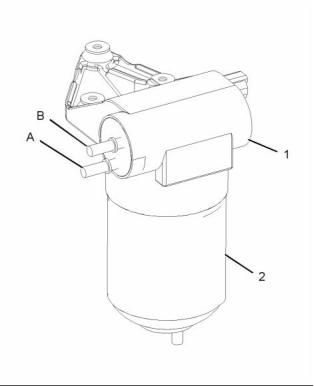

Table 1

Required Tools

Tool

A

Part Number

27610211

27610212

Part Description

Crankshaft Timing Pin

Camshaft Timing Pin

Qty

1

B

1

If excessive air is not seen at the inlet to the

fuel transfer pump, the air is entering the system

after the fuel transfer pump. Refer to Systems

Operation, Testing and Adjusting, “Fuel System -

Prime”.

If excessive air is seen at the inlet to the fuel

transfer pump, air is entering through the suction

side of the fuel system.

To avoid personal injury, always wear eye and face

protection when using pressurized air.

NOTICE

To avoid damage, do not use more than 55 kPa (8 psi)

to pressurize the fuel tank.

4. Pressurize the fuel tank to 35 kPa (5 psi). Do

not use more than 55 kPa (8 psi) in order to

avoid damage to the fuel tank. Check for leaks

in the fuel lines between the fuel tank and

the fuel transfer pump. Repair any leaks that

are found. Check the fuel pressure in order to

ensure that the fuel transfer pump is operating

properly. For information about checking the fuel

pressure, Refer to Systems Operation, Testing

and Adjusting, “Fuel System Pressure - Test”.

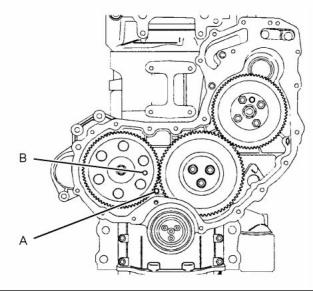

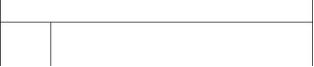

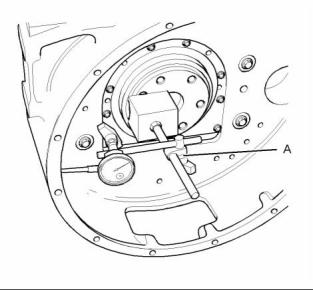

g01431408

Illustration 12

Typical example

(A) Hole for crankshaft timing pin

(B) Hole for camshaft timing pin

1. Remove the valve mechanism cover. Refer to

Disassembly and Assembly, “Valve Mechanism

Cover - Remove and Install”.

2. Remove the glow plugs. Refer to Disassembly

5. If the source of the air is not found, disconnect

the supply line from the fuel tank and connect an

external fuel supply to the inlet of the fuel transfer

pump. If this corrects the problem, repair the fuel

tank or the stand pipe in the fuel tank.

and Assembly, “Glow Plugs - Remove and Install”.

3. Remove the cover for the front housing. Refer

to Disassembly and Assembly, “Front Cover -

Remove and Install”.

Note: Tooling (A) can be inserted with the crankshaft

pulley still on the engine.

4. Rotate the crankshaft in the normal direction of the

engine until Tooling (B) can be inserted through

the camshaft gear and into the timing case.

Note: The camshaft gear can rotate a small amount

when Tooling (B) is installed.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

20

KENR6912

Testing and Adjusting Section

5. Carefully rotate the crankshaft in the normal

direction of the engine in order to align the hole in

the crankshaft with the hole in the timing case and

the cylinder block. Insert Tooling (A) fully into the

hole in the crankshaft web.

i02876576

Fuel Injection Pump Timing -

Adjust

Note: When Tooling (A) is inserted, number one

piston will be at top center.

Delphi DP210 and DP310 Fuel

Injection Pumps

6. Remove the Tooling (B) from the camshaft gear

and Tooling (A) from the crankshaft web.

The Delphi DP210 and DP310 fuel injection

pumps must be serviced by an authorized Delphi

technician. For repair information, contact your

Perkins distributor. The internal adjustment for the

pump timing is tamper proof. High idle and low idle

are factory set. High Idle adjustments can not be

made to the fuel pump.

7. Install the cover for the front housing. Refer

to Disassembly and Assembly, “Front Cover -

Remove and Install”.

8. Install the glow plugs. Refer to Disassembly and

Assembly, “Glow Plugs - Remove and Install”.

9. Install the valve mechanism cover. Refer to

Disassembly and Assembly, “Valve Mechanism

Cover - Remove and Install”.

i02563386

Fuel Quality - Test

i02876575

Fuel Injection Pump Timing -

Check

Note: Refer to Systems Operation, “Cleanliness

of Fuel System Components” for detailed

information on the standards of cleanliness that

must be observed during ALL work on the fuel

system.

Delphi DP210 and DP310 Fuel

Injection Pumps

Ensure that all adjustments and repairs are performed

by authorized personnel that have had the correct

training.

Note: The Delphi DP210 and DP310 fuel injection

pump timing cannot be checked. If you suspect that

the fuel injection pump timing is incorrect, contact

your Perkins distributor for further information.

Use the following procedure to test for problems

regarding fuel quality:

1. Determine if water and/or contaminants are

present in the fuel. Check the water separator (if

equipped). If a water separator is not present,

proceed to Step 2. Drain the water separator, if

necessary. A full fuel tank minimizes the potential

for overnight condensation.

Delphi DP210 and DP310 fuel injection pumps must

be serviced by an authorized Delphi technician. For

repair information, contact your Perkins distributor.

The internal adjustment for the pump timing is tamper

proof. High idle and low idle are factory set. High idle

adjustments cannot be made to the fuel pump.

Note: A water separator can appear to be full of fuel

when the water separator is actually full of water.

2. Determine if contaminants are present in the

fuel. Remove a sample of fuel from the bottom

of the fuel tank. Visually inspect the fuel sample

for contaminants. The color of the fuel is not

necessarily an indication of fuel quality. However,

fuel that is black, brown, and/or similar to sludge

can be an indication of the growth of bacteria or

oil contamination. In cold temperatures, cloudy

fuel indicates that the fuel may not be suitable for

operating conditions.

This document has been printed from SPI². Not for Resale

![]()

KENR6912

21

Testing and Adjusting Section

Refer to Operation and Maintenance Manual,

i02797519

“Fuel Recommendations” for more information.

Fuel System Pressure - Test

3. If fuel quality is still suspected as a possible

cause to problems regarding engine performance,

disconnect the fuel inlet line, and temporarily

operate the engine from a separate source of

fuel that is known to be good. This will determine

if the problem is caused by fuel quality. If fuel

quality is determined to be the problem, drain the

fuel system and replace the fuel filters. Engine

performance can be affected by the following

characteristics:

• Cetane number of the fuel

• Air in the fuel

• Other fuel characteristics

i02797518

Fuel System - Prime

If air enters the fuel system, the air must be purged

before the engine can be started. Air can enter the

fuel system when the following events occur:

• The fuel tank is empty or the tank has been partially

drained during normal operation.

g01235017

Illustration 13

• The low pressure fuel lines are disconnected.

(A and B) Fuel outlet

(1) Fuel transfer pump

(2) Fuel filter

• A leak exists in the low pressure fuel system during

engine operation.

The pressure test measures the output pressure of

the fuel transfer pump. Low fuel pressure and starting

difficulty may be indications of faults with the fuel

priming pump.

• The fuel filter or the fuel pump is replaced.

• The high pressure fuel lines are disconnected.

Delphi DP210 and DP310

Check the Function of the Fuel

Transfer Pump

The Delphi DP210 and DP310 fuel injection

pumps will eliminate the air from the fuel system

automatically. Position the starting switch to the RUN

position for three minutes. Air in the fuel and the fuel

lines will be purged from the system.

1. Make a note of the location of the fuel lines from

the fuel transfer pump. Remove the two lines from

fuel outlets (A) and (B).

2. Connect two suitable lengths of 5/16 inch rubber

hose to fuel outlets (A) and (B). Place the hoses

into a suitable container that is capable of holding

3 L (3.17 qt) of fuel.

3. Energize the fuel transfer pump until a constant

flow of fuel is running from the outlet for the supply

for the fuel injection pump.

Note: The flow from fuel outlet (B) for the return to

the fuel tank will have a slower flow rate.

This document has been printed from SPI². Not for Resale

![]()

![]()

22

KENR6912

Testing and Adjusting Section

4. Use a suitable tool in order to measure the

combined flow of both outlets with a stopwatch.

Fuel flow should be a minimum of 2 L/min

(0.53 US gpm).

5. If the combined flow is less than 2 L/min

(0.53 US gpm), replace the pump.

6. Reconnect the outlet lines in the correct positions.

7. Start the engine and check for any leakage of fuel

or air from the fuel lines.

Check the Function of the Pressure

Regulator

1. Remove the fuel line from fuel outlet (A) for the

supply to the fuel injection pump.

2. Install a suitable pipe with a tap for a pressure

gauge. Connect a 0 to 80 kPa (0 to 12 psi)

pressure gauge.

Note: One end of the pipe must be blanked.

3. Energize the fuel transfer pump for two minutes in

order to remove any trapped air.

4. Record the pressure reading at high idle. The

minimum pressure reading should be the following

values:

All Fuel Injection Pumps

Low idle ................................. 25 kPa (3.6 psi)

High idle ................................ 25 kPa (3.6 psi)

Note: The maximum pressure for the fuel injection

pump at idle speed or rated speed is 75 kPa

(10.9 psi).

5. Reconnect the fuel line. Energize the fuel transfer

pump for two minutes in order to remove any

trapped air.

Check for the following issues if the pressures are

outside of the above specifications.

• All electrical connections are installed correctly.

• There are no leaks in the fuel lines or connections.

• The O-ring on the fuel filter housing (2) does not

leak.

This document has been printed from SPI². Not for Resale

![]()

KENR6912

23

Testing and Adjusting Section

Air Inlet and Exhaust

System

Hot engine components can cause injury from

burns. Before performing maintenance on the

engine, allow the engine and the components to

cool.

i02797521

Air Inlet and Exhaust System

- Inspect

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

A general visual inspection should be made to the air

inlet and exhaust system. Make sure that there are

no signs of leaks in the system.

There will be a reduction in the performance of the

engine if there is a restriction in the air inlet system or

the exhaust system.

Hot engine components can cause injury from

burns. Before performing maintenance on the

engine, allow the engine and the components to

cool.

Making contact with a running engine can cause

burns from hot parts and can cause injury from

rotating parts.

When working on an engine that is running, avoid

contact with hot parts and rotating parts.

1. Inspect the engine air cleaner inlet and ducting

in order to ensure that the passageway is not

blocked or collapsed.

2. Inspect the engine air cleaner element. Replace a

dirty element with a clean element.

3. Check for dirt tracks on the clean side of the

engine air cleaner element. If dirt tracks are

observed, contaminants are flowing past the

element.

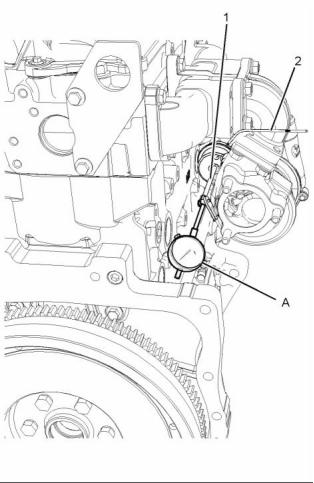

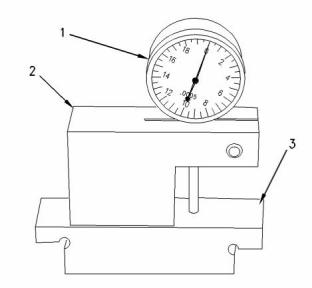

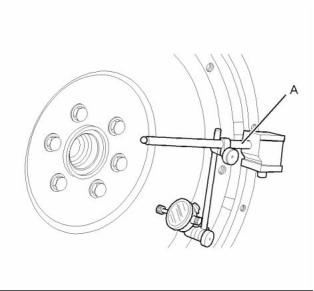

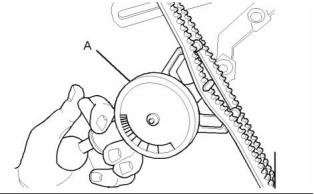

g01401677

Illustration 14

Typical example

i02875196

Note: The turbocharger is a nonserviceable item.

The pressure for the wastegate can be checked, but

not adjusted.

Wastegate - Test

1. Install Tooling (A). Tooling (A) is shown in

illustration 14. Align the dial gauge on Tooling (A)

to the actuator rod (1).

Table 2

Required Tools

Part

2. Remove the air hose to the actuator. Install a

suitable air line (2) that can be adjusted in order to

give the correct pressure.

Tool

Part Description

Qty

Number

A

21825617

Dial Gauge

1

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

24

KENR6912

Testing and Adjusting Section

3. Slowly apply air pressure to the wastegate so

that the actuator rod moves 1.0 mm (0.039 inch).

The air pressure should be within 107 to 117 kPa

(15.5 to 17.0 psi). Ensure that the dial indicator

returns to zero when the air pressure is released.

Repeat the test several times. This will ensure that

an accurate reading is obtained.

i02875199

Engine Crankcase Pressure

(Blowby) - Test

Damaged pistons or rings can cause too much

pressure in the crankcase. This condition will cause

the engine to run rough. There will be more than the

normal amount of fumes (blowby) rising from the

crankcase breather. The breather can then become

restricted in a very short time, causing oil leakage

at gaskets and seals that would not normally have

leakage. Blowby can also be caused by worn valve

guides or by a failed turbocharger seal.

Note: Do not exceed 205 kPa (30 psi) in order

to check the actuator. Refer to Specification,

“Turbocharger” for information on the correct

pressure setting for your actuator.

4. For more information on installing a new

turbocharger, contact a Perkins dealer.

i02875197

Exhaust Temperature - Test

Measure the Exhaust Temperature

When the engine runs at low idle, the temperature of

an exhaust manifold port can indicate the condition

of a fuel injection nozzle.

A low temperature indicates that no fuel is flowing to

the cylinder. An inoperative fuel injection nozzle or

a problem with the fuel injection pump could cause

this low temperature.

g00286269

Illustration 15

Typical air gauge

A very high temperature can indicate that too much

fuel is flowing to the cylinder. A malfunctioning

fuel injection nozzle could cause this very high

temperature.

Use a suitable air gauge in order to check the amount

of blowby.

i02797667

Use a suitable laser infrared thermometer in order to

check the exhaust temperature at the exhaust outlet

for each cylinder.

Compression - Test

Compare the temperature readings for each exhaust

outlet. Investigate any difference in the temperature

readings.

The cylinder compression test should only be used

in order to compare the cylinders of an engine.

The pressure in the cylinder should be between

300 to 500 kPa (43.5120 to 72.5200 psi). If one or

more cylinders vary by more than 350 kPa (51 psi),

the cylinder and related components may need to

be repaired.

A compression test should not be the only method

which is used to determine the condition of an engine.

Other tests should also be conducted in order to

determine if the adjustment or the replacement of

components is required.

Before the performance of the compression test,

make sure that the following conditions exist:

This document has been printed from SPI². Not for Resale

![]()

![]()

KENR6912

25

Testing and Adjusting Section

• The battery is in good condition.

• The battery is fully charged.

Not enough valve lash can be the cause of rapid

wear of the camshaft and valve lifters. Not enough

valve lash can indicate that the seats for the valves

are worn.

• The starting motor operates correctly.

• The valve lash is set correctly.

• All fuel injectors are removed.

• The fuel supply is disconnected.

Valves become worn due to the following causes:

• Fuel injectors that operate incorrectly

• Excessive dirt and oil are present on the filters for

the inlet air.

1. Install a gauge for measuring the cylinder

compression in the hole for a fuel injector.

• Incorrect fuel settings on the fuel injection pump.

• The load capacity of the engine is frequently

exceeded.

2. Operate the starting motor in order to turn the

engine. Record the maximum pressure which is

indicated on the compression gauge.

Too much valve lash can cause broken valve stems,

springs, and spring retainers. Too much valve lash

can be an indication of the following problems:

3. Repeat Steps 1 and 2 for all cylinders.

• Worn camshaft and valve lifters

• Worn rocker arms

i02875200

Engine Valve Lash -

Inspect/Adjust

• Bent pushrods

• Broken socket on the upper end of a pushrod

• Loose adjustment screw for the valve lash

Table 3

Required Tools

If the camshaft and the valve lifters show rapid wear,

look for fuel in the lubrication oil or dirty lubrication

oil as a possible cause.

Tool

Part Number

Part Description

Qty

A

26710298

Angled feeler gauge

1

The valve lash is measured between the top of the

valve stem and the rocker arm lever.

To prevent possible injury, do not use the starter

to turn the flywheel.

Note: An adjustment is not necessary if the

measurement of the valve lash is in the acceptable

range. Inspect the valve lash while the engine is

stopped. The temperature of the engine does not

change the valve lash setting.

Hot engine components can cause burns. Allow

additional time for the engine to cool before mea-

suring valve clearance.

Note: When the following procedures are performed,

the front housing must be installed.

Valve Lash Setting

Table 4

Inlet Valves

Exhaust Valves

Valve Lash

0.2 ± 0.05 mm

(0.008 ± 0.002

inch)

0.45 ± 0.05 mm

(0.018 ± 0.002 inch)

Refer to Systems Operation, Testing and Adjusting,

“Engine Design” for the location of the cylinder valves.

If the valve lash requires adjustment several times

in a short period of time, excessive wear exists in

a different part of the engine. Find the problem and

make necessary repairs in order to prevent more

damage to the engine.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

26

KENR6912

Testing and Adjusting Section

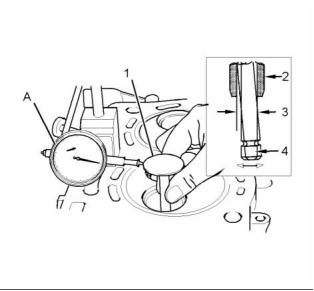

2. Rotate the crankshaft in a clockwise direction that

is viewed from the front of the engine. When the

inlet valve of the No 1 cylinder has opened and

the exhaust valve of the No 1 cylinder has not

completely closed measure the valve lash of the

inlet valve of No 2 cylinder and the exhaust valve

of No 3 cylinder. If necessary, make adjustment.

a. Lightly tap the rocker arm at the top of the

adjustment screw with a soft mallet. This

will ensure that the lifter seats against the

camshaft.

b. Loosen the valve adjustment screw locknut

that is on adjustment screw (1).

c. Place Tooling (A) between the rocker arm and

the valve. Turn adjustment screw (1) while the

valve adjustment screw locknut is being held

from turning. Adjust the valve lash until the

correct specification is achieved.

g01227408

Illustration 16

d. Tighten the adjustment locknut to a torque of

27 N·m (20 lb ft). Do not allow the adjustment

screw to turn while you are tightening the

adjustment locknut. Recheck the valve lash

after tightening the adjustment locknut.

Setting the valve lash

(1) Adjustment screw

(A) Angled Feeler gauge

Valve Lash Adjustment

3. Rotate the crankshaft in a clockwise direction that

is viewed from the front of the engine. When the

inlet valve of the No 2 cylinder has opened and

the exhaust valve of the No 2 cylinder has not

completely closed measure the valve lash of the

inlet valve for No 3 cylinder and the exhaust valve

for No 1 cylinder.

Accidental engine starting can cause injury or

death to personnel.

To prevent accidental engine starting, turn the ig-

nition switch to the OFF position, place a do not

operate tag at the ignition switch location and dis-

connect and tape the electrical connection to the

stop solenoid that is located on the fuel injection

pump.

If adjustment is necessary, refer to Step 2.

4. Rotate the crankshaft in a clockwise direction that

is viewed from the front of the engine. When the

inlet valve of the No 3 cylinder has opened and

the exhaust valve of the No 3 cylinder has not

completely closed measure the valve lash of the

inlet valve for No 1 cylinder and the exhaust valve

for No 2 cylinder.

Table 5

Inlet Valves

Exhaust Valves

Valve Lash

Firing Order

0.2 ± 0.05 mm

(0.008 ± 0.002 (0.018 ± 0.0020 inch)

inch)

0.45 ± 0.05 mm

If adjustment is necessary, refer to Step 2.

5. Install the valve mechanism cover. Refer to

Disassembly and Assembly, “Valve Mechanism

Cover - Remove and Install”.

1-2-3

(1)

(1) The No. 1 Cylinder is at the front of the engine.

1. Remove the valve mechanism cover. Refer to

Disassembly and Assembly, “Valve Mechanism

Cover - Remove and Install”.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

KENR6912

27

Testing and Adjusting Section

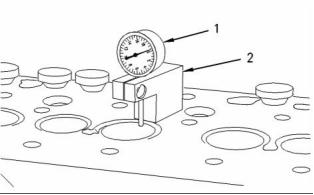

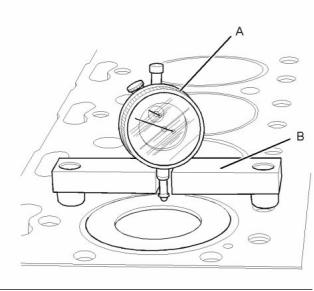

i02875207

2. Position gauge body (2) and dial indicator (1) in

order to measure the valve depth. Measure the

depth of the inlet valve and the exhaust valve

before the valve springs are removed.

Valve Depth - Inspect

Refer to Specifications, “Cylinder Head Valves”

for the minimum, the maximum, and the service

wear limits for the valve depth below the cylinder

head face.

Table 6

Required Tools

Part

Tool

Part Name

Qty

Number

If the valve depth below the cylinder head face

exceeds the service limit, use a new valve to

check the valve depth. If the valve depth still

exceeds the service limit, renew the cylinder head

or renew the valve seat inserts. If the valve depth

is within the service limit, renew the valves.

A

GE50002

Liner Projection Tool

1

3. Inspect the valves for cracks and other damage.

Check the valve stems for wear. Check that the

valve springs are the correct length under the

test force. Refer to Specifications, “Cylinder Head

Valves” for the dimensions and tolerances of the

valves and valve springs.

i02875210

Valve Guide - Inspect

Table 7

Required Tools

Tool

Part

Number

Part Name

Qty

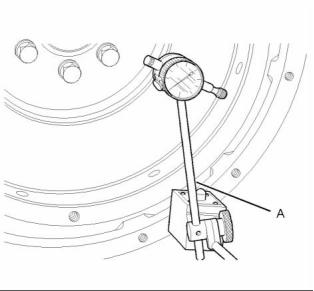

g00323908

Illustration 17

Liner Projection Tool

A

21825617

Dial Gauge

1

(1) Dial indicator

(2) Gauge body

(3) Gauge block

Perform this test in order to determine if a valve guide

should be replaced.

1. Use Tooling (A) in order to check the depths of

the inlet valves and the exhaust valves below the

face of the cylinder head. Use gauge block (3) to

zero dial indicator (1).

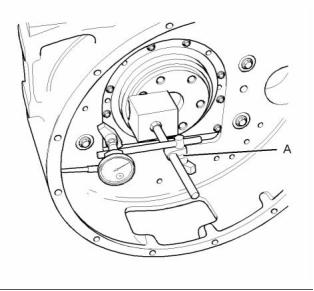

g00323909

Illustration 18

Measurement of the valve depth

(1) Dial indicator

(2) Gauge body

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

28

KENR6912

Testing and Adjusting Section

Refer to Specifications, “Cylinder Head Valves” for

the maximum clearance of the valve in the valve

guide.

g01235205

Illustration 19

(A) Dial gauge

(1) Valve head

(2) Valve guide

(3) Radial movement of the valve in the valve guide

(4) Valve stem

1. Place a new valve in the valve guide.

2. Place Tooling A with the magnetic base on the

face of the cylinder head.

3. Lift the edge of the valve head (1) to a distance

of 15.0 mm (0.60 inch).

4. Move the valve in a radial direction away from

Tooling (A). Make sure that the valve moves away

from Tooling (A) as far as possible. Position the

contact point of Tooling (A) on the edge of the

valve head (1). Set the position of the needle of

Tooling (A) to zero.

5. Move the valve in a radial direction toward Tooling

(A) as near as possible. Note the distance of

movement which is indicated on Tooling (A). If the

distance is greater than the maximum clearance

of the valve in the valve guide, replace the valve

guide.

When new valve guides are installed, new valves

and new valve seat inserts must be installed.

Valve guides and valve seat inserts are supplied

as an unfinished part. The unfinished valve guides

and unfinished valve seat inserts are installed in

the cylinder head. Then, the valve guides and

valve inserts are cut and reamed in one operation

with special tooling.

This document has been printed from SPI². Not for Resale

![]()

![]()

KENR6912

29

Testing and Adjusting Section

Lubrication System

Engine Oil Pressure - Test

Low Oil Pressure

i02875224

Engine Oil Pump - Inspect

i02875215

Table 8

Required Tools

Tool

Part Number

Part Description

Qty

A

CVT0014

Feeler gauge

1

The following conditions will cause low oil pressure.

• The oil level is low in the crankcase.

If any part of the oil pump is worn enough in order to

affect the performance of the oil pump, the oil pump

must be replaced.

• A restriction exists on the oil suction screen.

• Connections in the oil lines are leaking.

Perform the following procedures in order to inspect

the oil pump for clearances and torques.

• The connecting rod or the main bearings are worn.

• The rotors in the oil pump are worn.

Refer to Specifications, “Engine Oil Pump”.

1. Remove the oil pump from the engine. Refer to

Disassembly and Assembly, “Engine Oil Pump -

Remove”. Remove the cover of the oil pump.

• The oil pressure relief valve is operating incorrectly.

A worn oil pressure relief valve can allow oil to leak

through the valve which lowers the oil pressure.

Refer to Specifications, “Engine Oil Relief Valve” for

the correct operating pressure and other information.

2. Remove the outer rotor. Clean all of the parts.

Look for cracks in the metal or other damage.

When an engine that is turbocharged runs at the

normal temperature for operation and at high idle, the

oil pressure must be a minimum of 280 kPa (40 psi).

A lower pressure is normal at low idle.

Use a suitable pressure gauge in order to test the

pressure of the lubrication system.

High Oil Pressure

High oil pressure can be caused by the following

conditions.

• The spring for the oil pressure relief valve is

installed incorrectly.

• The plunger for the oil pressure relief valve

becomes jammed in the closed position.

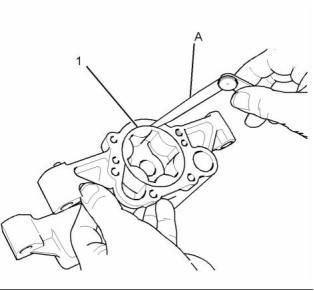

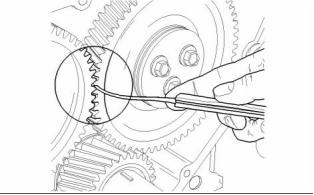

g01235471

Illustration 20

• Excessive sludge exists in the oil which makes the

viscosity of the oil too high.

Clearance for the outer rotor body

(1) Outer rotor to the body

(A) Feeler gauge

3. Install the outer rotor. Place Tooling (A) between

the outer body and the outer rotor in order to

measure the clearance of the outer rotor to the

body (1). Refer to Specifications, “Engine Oil

Pump”.

This document has been printed from SPI². Not for Resale

![]()

![]()

30

KENR6912

Testing and Adjusting Section

6. Clean the top face of the oil pump and the bottom

face of the cover. Install the cover on the oil

pump. Install the oil pump on the engine. Refer to

Disassembly and Assembly, “Engine Oil Pump -

Install”.

i02801063

Excessive Bearing Wear -

Inspect

When some components of the engine show bearing

wear in a short time, the cause can be a restriction in

an oil passage.

An engine oil pressure indicator may show that there

is enough oil pressure, but a component is worn

due to a lack of lubrication. In such a case, look at

the passage for the oil supply to the component.

A restriction in an oil supply passage will not allow

enough lubrication to reach a component. This will

result in early wear.

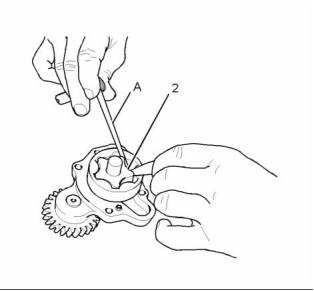

g01235472

Illustration 21

Clearance for the inner rotor

(2) Inner rotor to the outer rotor

(A) Feeler gauge

4. Place Tooling (A) between the inner rotor (2) and

the outer rotor in order to measure the clearance.

i02801065

Excessive Engine Oil

Consumption - Inspect

Engine Oil Leaks on the Outside of

the Engine

Check for leakage at the seals at each end of the

crankshaft. Look for leakage at the gasket for the

engine oil pan and all lubrication system connections.

Look for any engine oil that may be leaking from

the crankcase breather. This can be caused by

combustion gas leakage around the pistons. A dirty

crankcase breather will cause high pressure in the

crankcase. A dirty crankcase breather will cause the

gaskets and the seals to leak.

Engine Oil Leaks into the

Combustion Area of the Cylinders

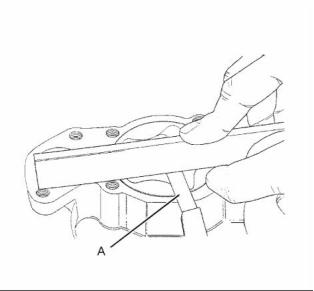

g01235624

Illustration 22

End play measurement for the rotor

(A) Feeler gauge

Engine oil that is leaking into the combustion area of

the cylinders can be the cause of blue smoke. There

are several possible ways for engine oil to leak into

the combustion area of the cylinders:

5. Measure the end play of the rotor with a straight

edge and Tooling (A). Refer to Specifications,

“Engine Oil Pump”.

• Failed valve stem seals

• Leaks between worn valve guides and valve stems

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

KENR6912

31

Testing and Adjusting Section

• Worn components or damaged components

(pistons, piston rings, or dirty return holes for the

engine oil)

• Incorrect installation of the compression ring and/or

the intermediate ring

• Leaks past the seal rings in the turbocharger shaft

• Overfilling of the crankcase

• Wrong dipstick or guide tube

• Sustained operation at light loads

Excessive consumption of engine oil can also

result if engine oil with the wrong viscosity is used.

Engine oil with a thin viscosity can be caused by fuel

leakage into the crankcase or by increased engine

temperature.

i02801067

Increased Engine Oil

Temperature - Inspect

Look for a restriction in the oil passages of the oil

cooler. The oil temperature may be higher than

normal when the engine is operating. In such a

case, the oil cooler may have a restriction. High oil

temperature can be a cause of low oil pressure.

Determine if the oil cooler bypass valve is held in the

open position. This condition will allow the oil to pass

through the valve instead of the oil cooler. The oil

temperature will increase.

This document has been printed from SPI². Not for Resale

![]()

32

KENR6912

Testing and Adjusting Section

Cooling System

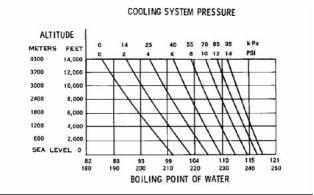

6. Check the filler cap. A pressure drop in the cooling

system can cause the boiling point to be lower.

This can cause the cooling system to boil. Refer

to Systems Operation, Testing and Adjusting,

“Cooling System - Test”.

i02801080

Cooling System - Check

(Overheating)

7. Check the cooling system hoses and clamps.

Damaged hoses with leaks can normally be

seen. Hoses that have no visual leaks can soften

during operation. The soft areas of the hose

can become kinked or crushed during operation.

These areas of the hose can cause a restriction

in the coolant flow. Hoses become soft and/or get

cracks after a period of time. The inside of a hose

can deteriorate, and the loose particles of the

hose can cause a restriction of the coolant flow.

Above normal coolant temperatures can be caused

by many conditions. Use the following procedure

to determine the cause of above normal coolant