產(chǎn)品中心

美國強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢圖冊

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國道依茨 韓國大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

珀金斯Perkins1204E-E44TA(TTA)測試調(diào)整(英文)

詳細(xì)描述

Systems Operation

Testing and Adjusting

1204E-E44TA and 1204E-E44TTA

Industrial Engines

MK (Engine)

ML (Engine)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

Important Safety Information

Most accidents tha t involve produc t op eration, ma intena nc e and repair are caus ed by failure to

ob serve basic safety rules or precautions . An accident can often be avoided by recog nizing pote ntially

ha za rdous situations before an accident oc curs . A person mus t be alert to pote ntial ha za rds. This

person should also ha ve the ne cessary training, skills and tools to perform the se func tions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Sa fety precautions and warning s are provided in this ma nua l and on the produc t. If the se ha za rd

warning s are not he eded, bod ily injury or death could oc cur to you or to othe r persons .

The ha za rds are identified by the “Safety Alert Symb ol” and followed by a “Signa l Word” suc h as

“DANGER”, “WARNING” or “CAUTION”. The Sa fety Alert “WARNING” label is shown below.

The me aning of this safety alert symb ol is as follows:

Attention! Become Alert! Your Safety is Involved.

The me ssage tha t appears und er the warning explains the ha za rd and can be either written or

pictorially presente d.

Op erations tha t ma y caus e produc t dama ge are identified by “NOTICE” labels on the produc t and in

this pub lication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The informa tion, specifications , and illustrations in this pub lication are on the basis of informa tion tha t

was available at the time tha t the pub lication was written. The specifications , torque s, pressure s,

me asure me nts , adjustme nts , illustrations , and othe r items can cha ng e at any time. These cha ng es can

affect the service tha t is given to the produc t. Ob tain the comp lete and mos t current informa tion before

you start any job. Pe rkins dealers or Pe rkins distributors ha ve the mos t current informa tion available.

When replacement parts are required for this

product Perkins recommends using Perkins

replacement parts.

Failure to heed this warning can lead to prema-

ture failures, product damage, personal injury or

death.

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9124-01

3

Table of Contents

Table of Contents

Position the Valve Mechanism Before Maintenance

Procedures .......................................................... 86

Piston Ring Groove - Inspect ................................ 86

Connecting Rod - Inspect ..................................... 87

Cylinder Block - Inspect ........................................ 88

Cylinder Head - Inspect ........................................ 88

Piston Height - Inspect .......................................... 89

Flywheel - Inspect ................................................. 90

Flywheel Housing - Inspect ................................... 90

Gear Group - Inspect ............................................ 92

Crankshaft Pulley - Check .................................... 92

Systems Operation Section

General Information

Introduction ............................................................ 4

Engine Operation

Basic Engine ......................................................... 10

Air Inlet and Exhaust System (Single

Turbocharger) ..................................................... 14

Air Inlet and Exhaust System (Series

Electrical System

Alternator - Test .................................................... 94

Battery - Test ......................................................... 96

Charging System - Test ........................................ 96

V-Belt - Test .......................................................... 97

Electric Starting System - Test .............................. 98

Turbochargers) .................................................... 20

Clean Emissions Module ...................................... 25

Cooling System .................................................... 27

Lubrication System .............................................. 29

Electrical System ................................................. 29

Cleanliness of Fuel System Components ............. 31

Fuel Injection ....................................................... 31

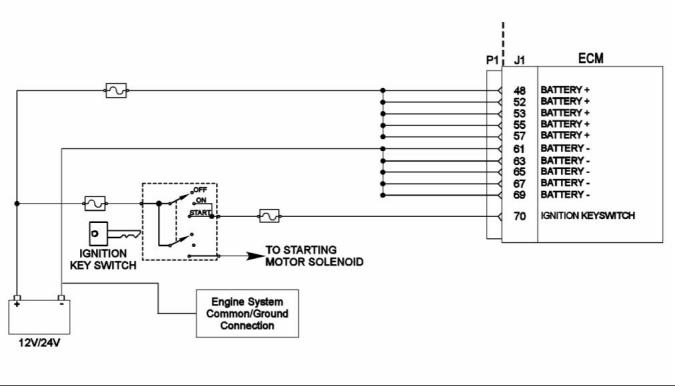

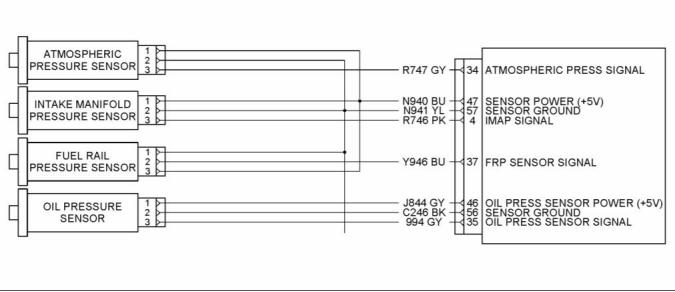

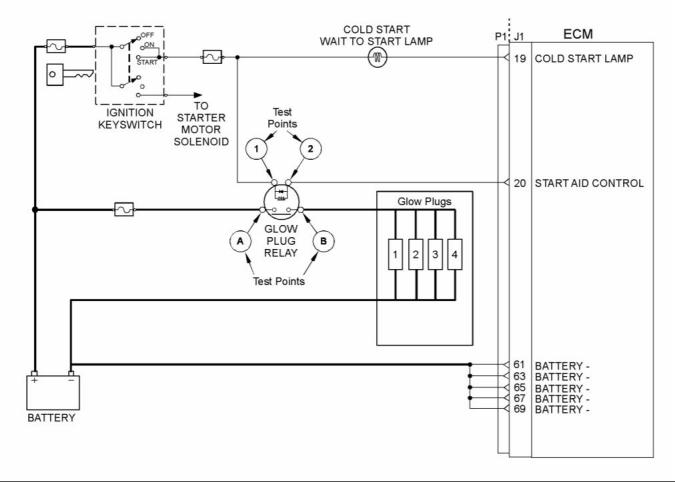

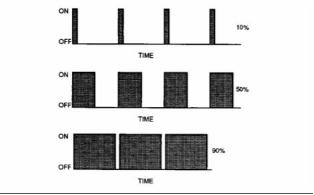

Electronic Control System ................................... 39

Power Sources ..................................................... 52

Glossary of Electronic Control Terms ................... 55

Index Section

Index ................................................................... 102

Testing and Adjusting Section

Fuel System

Fuel System - Inspect ........................................... 61

Air in Fuel - Test .................................................... 61

Finding Top Center Position for No. 1 Piston ........ 63

Fuel Injection Timing - Check ............................... 64

Fuel Quality - Test ................................................. 65

Fuel System - Prime ............................................. 65

Gear Group (Front) - Time .................................... 66

Air Inlet and Exhaust System

Air Inlet and Exhaust System - Inspect ................. 67

Turbocharger - Inspect (Series Turbochargers) .... 68

Turbocharger - Inspect (Single Turbocharger) ...... 71

Exhaust Cooler (NRS) - Test ................................ 73

Compression - Test ............................................... 74

Engine Valve Lash - Inspect ................................. 75

Valve Depth - Inspect ............................................ 77

Valve Guide - Inspect ............................................ 77

Lubrication System

Engine Oil Pressure - Test .................................... 79

Engine Oil Pump - Inspect .................................... 79

Excessive Bearing Wear - Inspect ........................ 80

Excessive Engine Oil Consumption - Inspect ....... 80

Increased Engine Oil Temperature - Inspect ........ 81

Cooling System

Cooling System - Check ....................................... 82

Cooling System - Inspect ...................................... 82

Cooling System - Test ........................................... 83

Engine Oil Cooler - Inspect ................................... 84

Water Temperature Regulator - Test ..................... 85

Water Pump - Inspect ........................................... 85

Basic Engine

This document is printed from SPI². Not for RESALE

![]()

4

Systems Operation Section

KENR9124-01

Systems Operation Section

General Information

The crankshaft gear turns the idler gear which then

turns the following gears:

• the camshaft gear

• the accessory drive gear (if equipped)

• the fuel injection pump gear

• the water pump gear

i04129551

Introduction

The camshaft runs at half the rpm of the crankshaft.

The fuel injection pump runs at the same rpm as the

crankshaft.

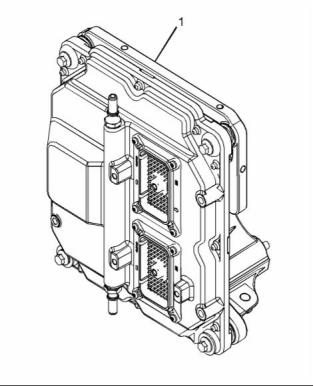

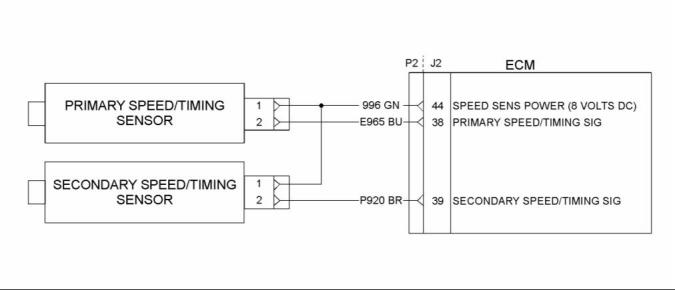

The 1204E diesel engine is electronically controlled.

The 1204E engine has an Electronic Control Module

(ECM) that receives signals from the fuel injection

pump and other sensors in order to control the

electronic unit injector. The fuel injection pump

supplies fuel to the high-pressure manifold (Rail).

The high-pressure manifold (Rail) distributes fuel to

the electronic unit injectors.

The fuel injection pump that is installed on the left

side of the engine is gear-driven from the timing

case. The fuel is transferred to the fuel injection

pump by an external electric transfer pump. The

electric transfer pump draws fuel across a suction

strainer that supplies fuel to the primary fuel filter

and the secondary fuel filter. The fuel then travels to

the fuel injection pump. A pressure regulator that is

installed in the low-pressure fuel system controls the

fuel pressure to the fuel injection pump. The pressure

regulator regulates the fuel at an absolute pressure

of 150 kPa (22 psi) when the engine is at idle speed.

The four cylinders are arranged in-line. The cylinder

head assembly has two inlet valves and two exhaust

valves for each cylinder. The ports for the exhaust

valves are on the right side of the cylinder head. The

ports for the inlet valves are on the left side of the

cylinder head. Each cylinder valve has a single valve

spring.

The fuel injection pump increases the fuel to a

maximum pressure of 200 MPa (2900 psi). The fuel

injection pump delivers the fuel to the high-pressure

manifold (Rail). The fuel injection pump is not

serviceable. The engine uses speed sensors and

the Electronic Control Module to control the engine

speed.

Each cylinder has a piston cooling jet that is installed

in the cylinder block. The piston cooling jet sprays

engine oil onto the inner surface of the piston in order

to cool the piston. The pistons have a Quiescent

combustion chamber in the top of the piston in order

to achieve clean exhaust emissions. The piston pin is

off-center in order to reduce the noise level.

For the specifications of the 1204E engine, refer to

the Specifications, “Engine Design”.

The pistons have two compression rings and an oil

control ring. The groove for the top ring has a hard

metal insert in order to reduce wear of the groove.

The skirt has a layer of graphite in order to reduce

the risk of seizure when the engine is new. The

correct piston height is important in order to ensure

that the piston does not contact the cylinder head.

The correct piston height also ensures the efficient

combustion of fuel which is necessary in order to

conform to requirements for emissions.

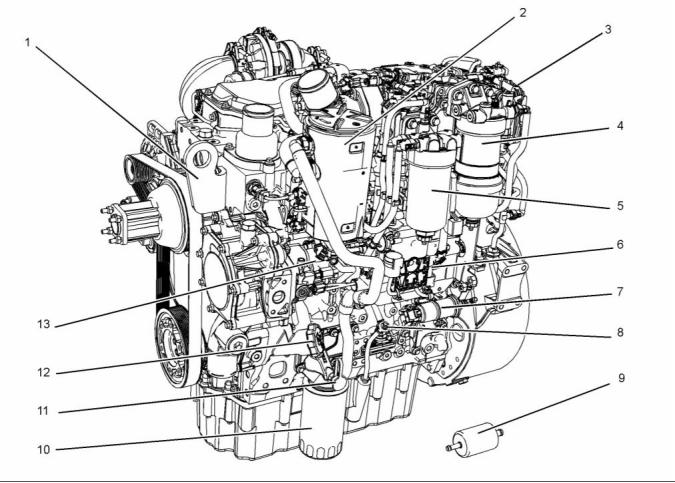

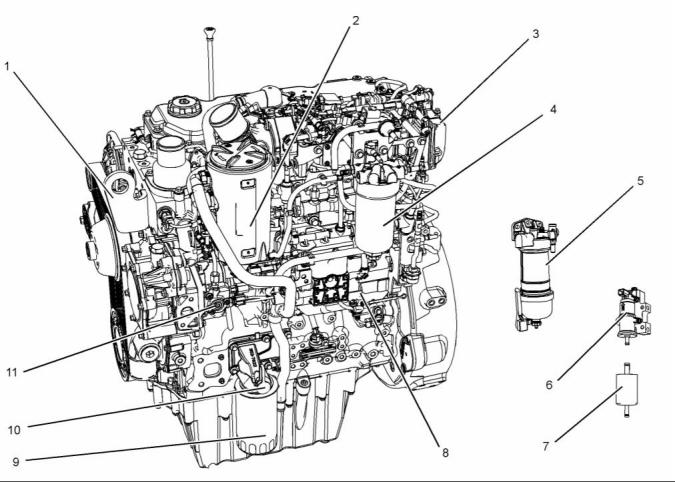

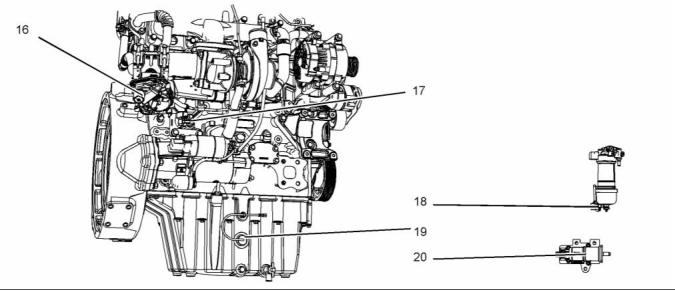

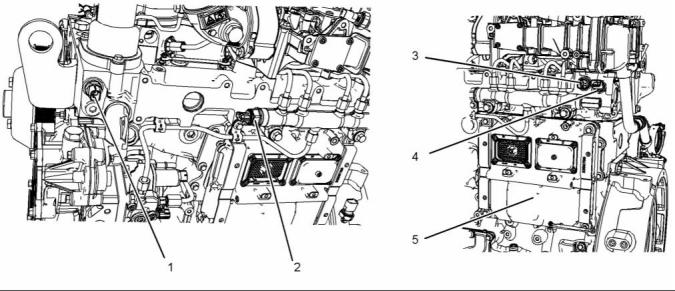

The following model views show a typical 1204E

engine. Due to individual applications, your engine

may appear different from the illustrations.

The crankshaft has five main bearing journals. End

play is controlled by thrust washers which are located

on both sides of the number 3 main bearing.

The timing case is made of aluminum or cast iron.

The timing gears are stamped with timing marks in

order to ensure the correct assembly of the gears.

When the number 1 piston is at the top center

position of the compression stroke, the marked teeth

on the idler gear will align with the marks that are

on the fuel injection pump gear, the camshaft gear,

and the gear on the crankshaft. There are no timing

marks on the rear face of the timing case.

This document is printed from SPI². Not for RESALE

![]()

KENR9124-01

5

Systems Operation Section

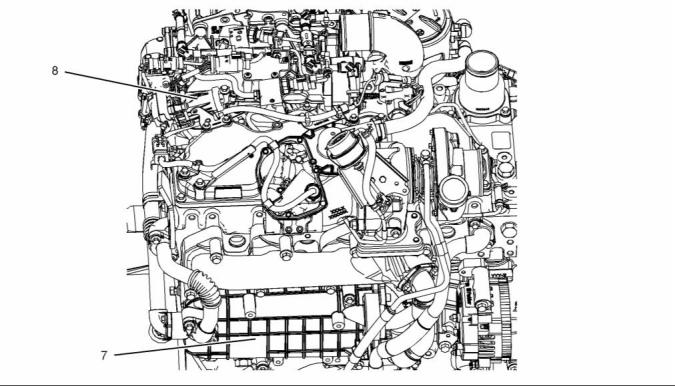

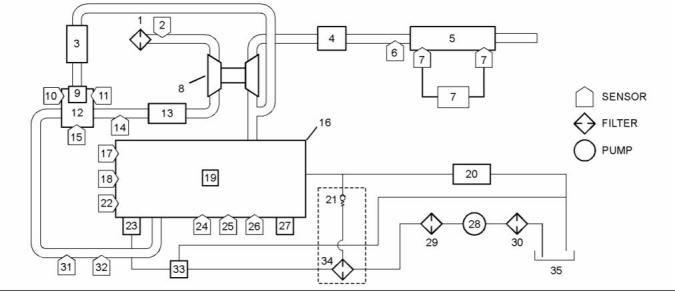

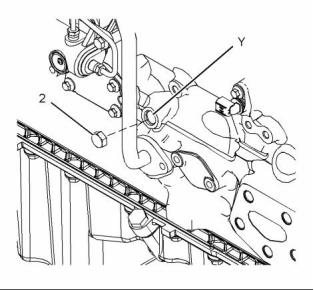

1204E-E44TTA Engine with Series

Turbochargers

g02409511

Illustration 1

Typical example

(1) Front lifting eye

(6) Electronic Control Module (ECM)

(11) Oil sampling valve

(2) Crankcase breather

(3) NOx Reduction System (NRS)

(4) Primary fuel filter

(7) Fuel priming pump

(8) Oil gauge (dipstick)

(9) Fuel strainer

(12) Oil filler

(13) Fuel injection pump

(5) Secondary fuel filter

(10) Oil filter

This document is printed from SPI². Not for RESALE

![]()

![]()

6

Systems Operation Section

KENR9124-01

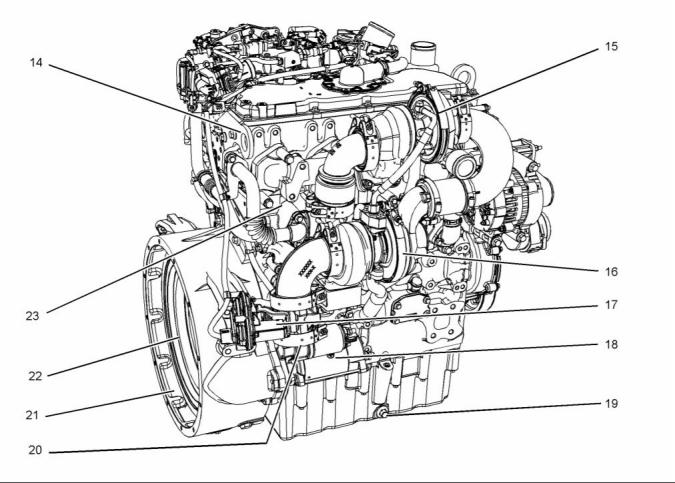

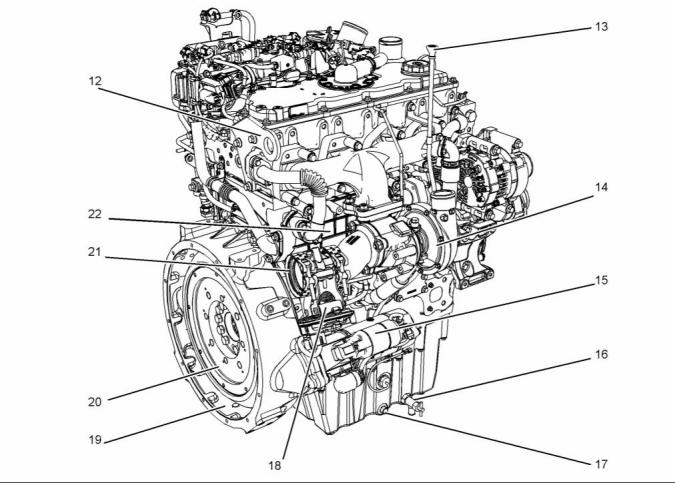

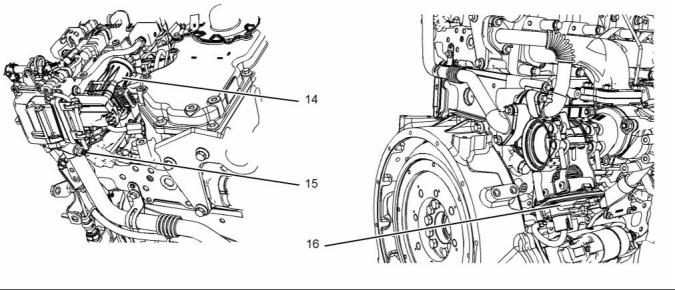

g02409512

Illustration 2

Typical example

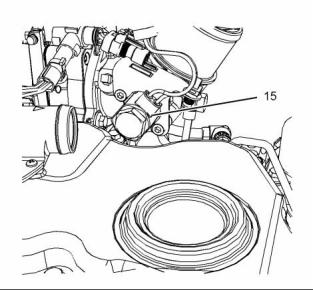

(14) Rear lifting eye

(18) Starting motor

(19) Oil drain plug

(20) Exhaust outlet

(21) Flywheel housing

(22) Flywheel

(23) Exhaust gas cooler (NRS)

(15) High-pressure turbocharger

(16) Low-pressure turbocharger

(17) Back pressure valve

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9124-01

7

Systems Operation Section

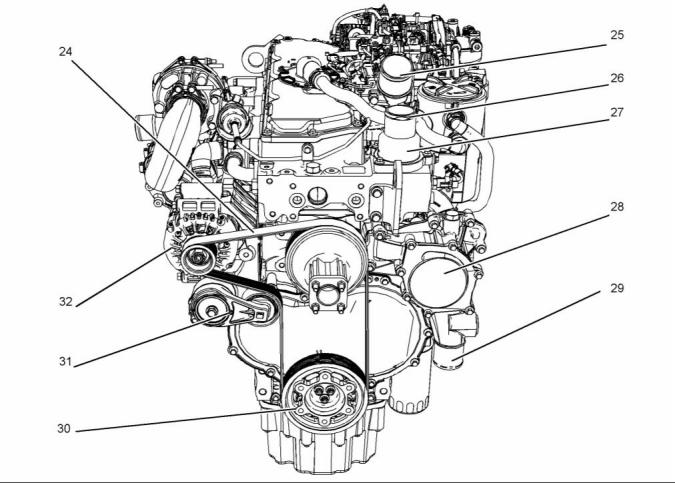

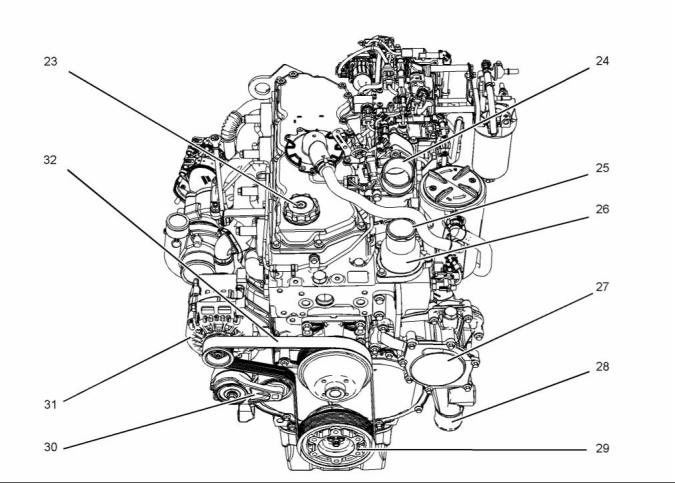

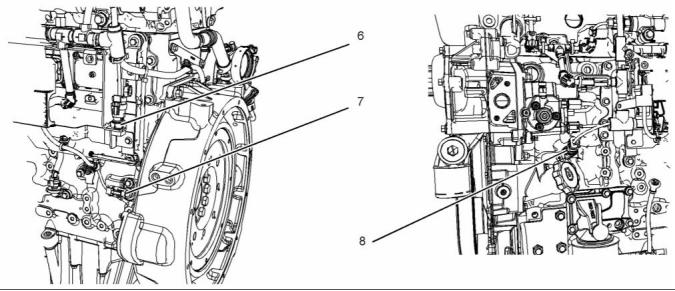

g02409862

Illustration 3

Typical example

(24) Belt

(25) Connection for air inlet

(26) Coolant outlet connection

(27) Water temperature regulator housing

(28) Water pump

(29) Inlet connection for the coolant

(30) Crankshaft pulley

(31) Belt tensioner

(32) Alternator

This document is printed from SPI². Not for RESALE

![]()

![]()

8

Systems Operation Section

KENR9124-01

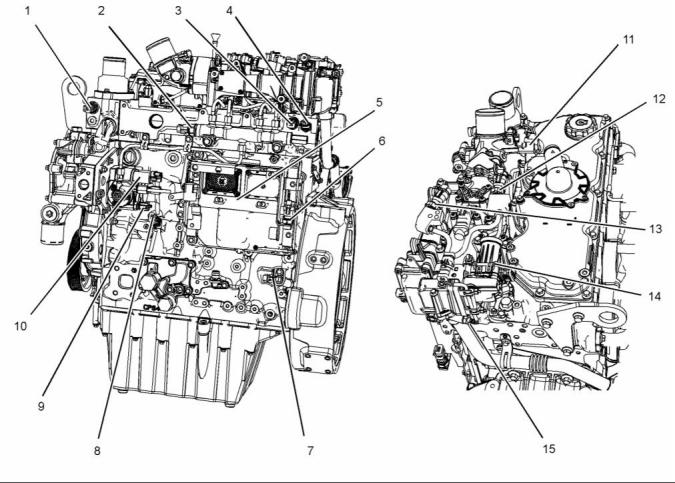

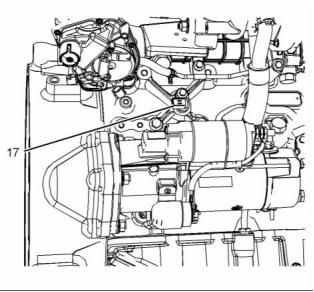

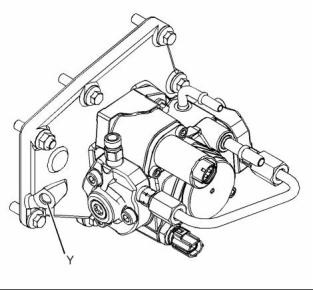

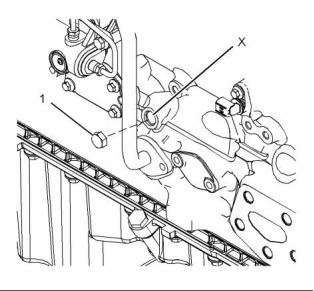

1204E-E44TA Engine with Single

Turbocharger

g02407436

Illustration 4

Typical example

(1) Front lifting eye

(5) Primary fuel filter

(9) Oil filter

(2) Crankcase breather

(3) NOx Reduction System (NRS)

(4) Secondary fuel filter

(6) Fuel priming pump

(7) Fuel strainer

(8) Electronic Control Module (ECM)

(10) Oil sampling valve

(11) Fuel injection pump

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9124-01

9

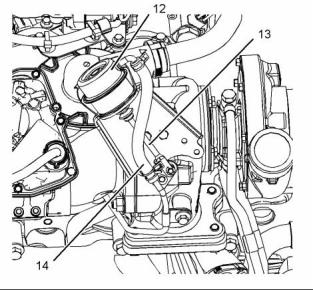

Systems Operation Section

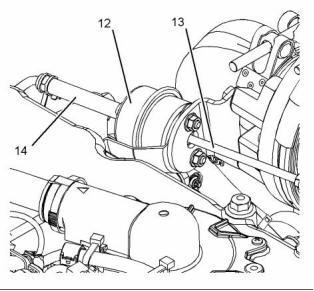

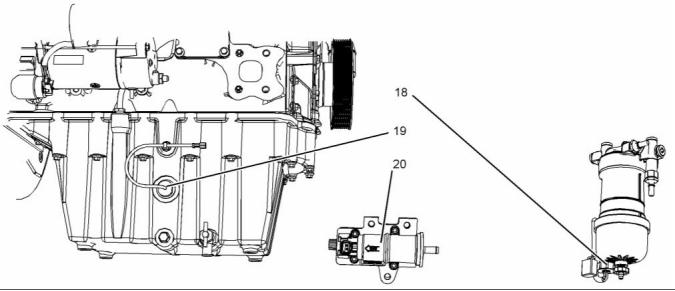

g02407536

Illustration 5

Typical example

(12) Rear lifting eye

(13) Oil gauge (dipstick)

(14) Turbocharger

(16) Oil drain valve

(17) Oil drain plug

(18) Back pressure valve

(19) Flywheel housing

(20) Flywheel

(21) Exhaust outlet

(22) Exhaust gas cooler (NRS)

(15) Starting motor

This document is printed from SPI². Not for RESALE

![]()

![]()

10

KENR9124-01

Systems Operation Section

g02407537

Illustration 6

Typical example

(23) Oil filler

(27) Water pump

(31) Alternator

(32) Belt

(24) Connection for air inlet

(25) Outlet connection for the coolant

(26) Water temperature regulator housing

(28) Inlet connection for the coolant

(29) Crankshaft pulley

(30) Belt tensioner

Engine Operation

Basic Engine

Introduction

• Connecting rods

• Crankshaft

i04135810

• Crankshaft pulley

• Timing gear case and gears

• Camshaft

The eight major mechanical components of the basic

engine are the following parts:

• Cylinder block

• Cylinder head

• Pistons

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9124-01

11

Systems Operation Section

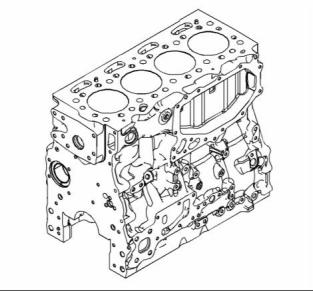

Cylinder Block

Cylinder Head

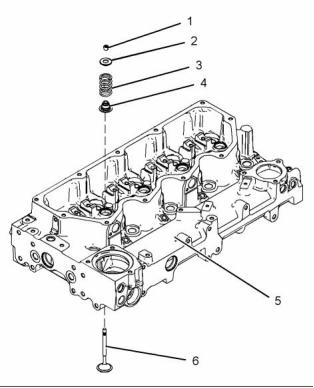

g02149272

Illustration 7

Typical example

The cast iron cylinder block for the four cylinder

engine has four cylinders which are arranged in-line.

The cylinder block is made of cast iron. The cylinder

block provides support for the full length of the

cylinder bores. The cylinder bores are machined into

the block.

g02466936

Illustration 8

Typical example

(1) Valve keepers

(2) Valve spring retainer

(3) Valve spring

The cylinders are honed to a specially controlled

finish in order to ensure long life and low oil

consumption.

The engine has a cast iron cylinder head (5). The

inlet manifold is integral within the cylinder head.

There are two inlet valves and two exhaust valves for

each cylinder. Each pair of valves (6) are connected

by a valve bridge that is controlled by a pushrod valve

system. The ports for the inlet valves are on the left

side of the cylinder head. The ports for the exhaust

valves are on the right side of the cylinder head. The

valve stems move in valve guides that are pressed

into the cylinder head. There is a renewable stem

seal (4) that fits over the top of the valve guide. The

valve seats are replaceable.

The cylinder block has five main bearings which

support the crankshaft. Thrust washers are installed

on both sides of number 3 main bearing in order to

control the end play of the crankshaft. The thrust

washers can only be installed one way.

Passages supply the lubrication for the crankshaft

bearings. These passages are machined into the

cylinder block.

Cooling passages are cast into the cylinder block in

order to allow the circulation of coolant.

The cylinder block has a bush that is installed for the

front camshaft journal. The other camshaft journals

run directly in the cylinder block.

The engine has a cooling jet that is installed in the

cylinder block for each cylinder. The piston cooling

jet sprays lubricating oil onto the inner surface of the

piston in order to cool the piston.

A Multi-Layered Steel (MLS) cylinder head gasket is

used between the engine block and the cylinder head

in order to seal combustion gases, water, and oil.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

12

KENR9124-01

Systems Operation Section

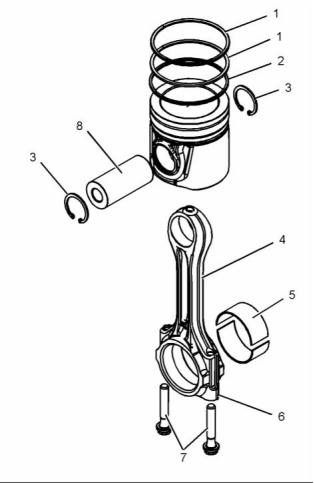

Pistons, Rings, and Connecting

rods

The connecting rods (4) are machined from forged

steel. The connecting rods have bearing caps (6)

that are fracture split. Two connecting rod bearings

(5) are installed between the connecting rod (4) and

the bearing cap (6). The bearing caps on fracture

split connecting rods are retained with Torx bolts (7).

Connecting rods with bearing caps that are fracture

split have the following characteristics:

• The splitting produces an accurately matched

surface on each side of the fracture for improved

strength.

• The correct connecting rod must be installed with

the correct bearing cap. Each connecting rod and

bearing cap have an unique serial number. When a

connecting rod is assembled the serial numbers for

the connecting rod and bearing cap must match.

Crankshaft

g02466938

Illustration 9

Typical example

The pistons (9) have a Quiescent combustion

chamber in the top of the piston in order to provide

an efficient mix of fuel and air. The piston pin (8) is

off-center in order to reduce the noise level. The

position pin (8) is retained in the correct position by

two circlips (3).

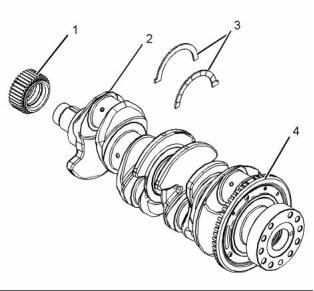

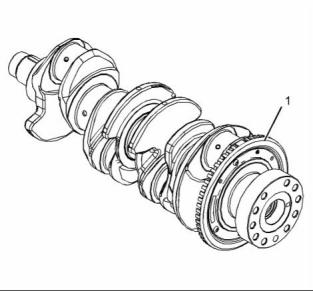

g02155439

Illustration 10

Typical example

(1) Crankshaft gear

(2) Crankshaft

(3) Crankshaft thrust washers

(4) Crankshaft timing ring

The pistons have two compression rings (1) and an

oil control ring (2). The groove for the top ring has

a hard metal insert in order to reduce wear of the

groove. The piston skirt has a low friction coating in

order to reduce the risk of seizure when the engine

is new.

The crankshaft can be a spheroidal graphite iron

casting or a steel forging.

The crankshaft has five main journals. Thrust

washers are installed on both sides of number 3

main bearing in order to control the end play of the

crankshaft.

The correct piston height is important in order to

ensure that the piston does not contact the cylinder

head. The correct piston height also ensures the

efficient combustion of fuel which is necessary in

order to conform to requirements for emissions.

The crankshaft changes the linear energy of the

pistons and connecting rods into rotary torque in

order to power external equipment.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

KENR9124-01

13

Systems Operation Section

A gear at the front of the crankshaft drives the timing

gears. The crankshaft gear turns the idler gear which

then turns the following gears:

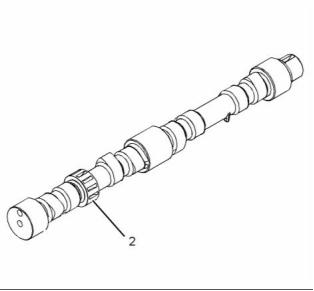

The camshaft rotates at half the engine speed. The

fuel injection pump rotates at engine speed.

Camshaft

• Camshaft gear

The engine has a single camshaft. The camshaft

is made of cast iron. The camshaft lobes are chill

hardened.

• Fuel injection pump and fuel transfer pump

• The idler gear is driven by the crankshaft gear

which turns the gear of the lubricating oil pump.

The camshaft is driven at the front end. As the

camshaft turns, the camshaft lobes move the valve

system components. The valve system components

move the cylinder valves.

Lip type seals are used on both the front of the

crankshaft and the rear of the crankshaft.

A timing ring is installed to the crankshaft. The timing

ring is used by the ECM in order to measure the

engine speed and the engine position.

The camshaft gear must be timed to the crankshaft

gear. The relationship between the lobes and the

camshaft gear causes the valves in each cylinder to

open at the correct time. The relationship between

the lobes and the camshaft gear also causes the

valves in each cylinder to close at the correct time.

A ring gear for the balancer can be installed to the

crankshaft. When a balancer is installed, the engine

oil pump is an integral part of the balancer assembly.

The ring gear for the balancer drives the balancer.

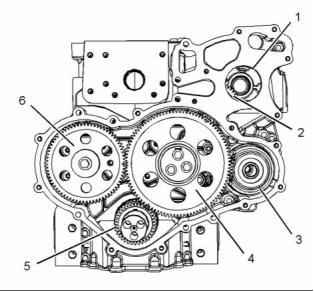

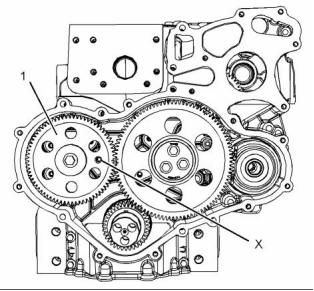

Gears and Timing Gear Case

g02212814

Illustration 11

Typical example

(1) Hole for the water pump gear

(3) Position of the accessory drive gear

The crankshaft oil seal is mounted in the cover of

the timing case. The timing case cover is made from

sound-deadened steel or cast iron.

The timing gears are made of steel.

The crankshaft gear (5) drives an upper idler gear

(4) and a lower idler gear. The upper idler gear (4)

drives the camshaft gear (6) and the fuel injection

pump gear (2). The lower idler gear drives the oil

pump. The water pump drive gear is driven by the

fuel injection pump gear.

This document is printed from SPI². Not for RESALE

![]()

![]()

14

KENR9124-01

Systems Operation Section

i04302990

Air Inlet and Exhaust System

(Single Turbocharger)

g02469917

Illustration 12

Air inlet and exhaust system

(1) Aftercooler core

(2) Air filter

(3) Diesel particulate filter

(4) Back pressure valve

(5) Turbocharger

(6) Wastegate actuator

(7) Exhaust cooler (NRS)

(8) Exhaust gas valve (NRS)

(9) Wastegate regulator

The components of the air inlet and exhaust system

control the quality of air and the amount of air that is

available for combustion. The air inlet and exhaust

system consists of the following components:

• Cylinder head, injectors, and glow plugs

• Valves and valve system components

• Piston and cylinder

• Air cleaner

• Exhaust manifold

• Exhaust cooler (NRS)

• Exhaust gas valve (NRS)

• Turbocharger

• Diesel oxidation catalyst

• Diesel particulate filter

• Aftercooler

• Inlet manifold

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9124-01

15

Systems Operation Section

Air is drawn in through the air cleaner into the air inlet

of the turbocharger by the turbocharger compressor

wheel. The air is compressed to a pressure of about

150 kPa (22 psi) and heated to about 120° C (248° F)

before the air is forced to the aftercooler. As the

air flows through the aftercooler the temperature of

the compressed air lowers to about 55° C (131° F).

Cooling of the inlet air assists the combustion

efficiency of the engine. Increased combustion

efficiency helps achieve the following benefits:

• Lower fuel consumption

• Increased power output

• Reduced NOx emission

• Reduced particulate emission

From the aftercooler, the air flows to the exhaust gas

valve (NRS). A mixture of air and exhaust gas is then

forced into the inlet manifold. Air flow from the inlet

manifold to the cylinders is controlled by inlet valves.

There are two inlet valves and two exhaust valves for

each cylinder. The inlet valves open when the piston

moves down on the intake stroke. When the inlet

valves open, cooled compressed air from the inlet

port is forced into the cylinder. The complete cycle

consists of four strokes:

• Inlet

• Compression

• Power

• Exhaust

On the compression stroke, the piston moves back

up the cylinder and the inlet valves close. The cool

compressed air is compressed further. This additional

compression generates more heat.

Note: If the cold starting system is operating, the

glow plugs will also heat the air in the cylinder.

Just before the piston reaches the top center (TC)

position, the ECM operates the electronic unit

injector. Fuel is injected into the cylinder. The air/fuel

mixture ignites. The ignition of the gases initiates the

power stroke. Both the inlet and the exhaust valves

are closed and the expanding gases force the piston

downward toward the bottom center (BC) position.

From the BC position, the piston moves upward.

This initiates the exhaust stroke. The exhaust valves

open. The exhaust gases are forced through the

open exhaust valves into the exhaust manifold.

This document is printed from SPI². Not for RESALE

![]()

16

KENR9124-01

Systems Operation Section

g02469919

Illustration 13

Typical example

The NOx Reduction System (NRS) operates with

the transfer of the hot exhaust gas from the exhaust

manifold to the exhaust cooler (7). The hot exhaust

gas is cooled in the exhaust cooler. The now cooled

exhaust gas passes through the assembly of exhaust

gas valve.

Exhaust gases from the exhaust manifold enter

the inlet of the turbocharger in order to turn the

turbocharger turbine wheel. The turbine wheel is

connected to a shaft that rotates. The exhaust gases

pass from the turbocharger through the following

components: exhaust outlet, back pressure valve,

Diesel Oxidation Catalyst (DOC), Diesel Particulate

Filter (DPF), and exhaust pipe.

The reed valves that are located in the exhaust gas

valve (NRS) has one main function. The one main

function is to prevent the reverse flow of charge air

from the inlet side of the engine to the exhaust side

of the engine.

As the electronically controlled valve (8) starts to

open the flow of cooled exhaust gas from the exhaust

cooler (7) mixes with the air flow from the charge air

aftercooler. The mixing of the cooled exhaust gas and

the air flow from the charge air aftercooler reduces

the oxygen content of the gas mixture. This results in

a lower combustion temperature, so decreases the

production of NOx.

As the demand for more cooled exhaust gas

increases the electronically controlled valve opens

further. The further opening of the valve increases

the flow of cooled exhaust gas from the exhaust

cooler. As the demand for cooled exhaust gas

decreases, the electronically controlled valve closes.

This decreases the flow of cooled exhaust gas from

the exhaust cooler.

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9124-01

17

Systems Operation Section

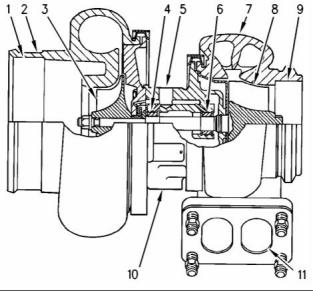

Turbocharger

g02469997

Illustration 15

g00302786

Illustration 14

Typical example

(12) Wastegate actuator

(13) Actuating lever

(14) Line (boost pressure)

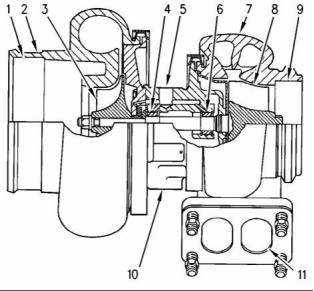

Typical example of a cross section of a turbocharger

(1) Air intake

(2) Compressor housing

(3) Compressor wheel

(4) Bearing

(5) Oil inlet port

(6) Bearing

(7) Turbine housing

(8) Turbine wheel

(9) Exhaust outlet

(10) Oil outlet port

(11) Exhaust inlet

The turbocharger is mounted on the outlet of the

exhaust manifold. The exhaust gas from the exhaust

manifold enters the exhaust inlet (11) and passes

through the turbine housing (7) of the turbocharger.

Energy from the exhaust gas causes the turbine

wheel (8) to rotate. The turbine wheel is connected

by a shaft to the compressor wheel (3).

As the turbine wheel rotates, the compressor wheel

is rotated. The rotation of the compressor wheel

causes the intake air to be pressurized through the

compressor housing (2) of the turbocharger.

g02151895

Illustration 16

Typical example

(15) Wastegate regulator

When the load on the engine increases, more fuel

is injected into the cylinders. The combustion of

this additional fuel produces more exhaust gases.

The additional exhaust gases cause the turbine and

the compressor wheels of the turbocharger to turn

faster. As the compressor wheel turns faster, air is

compressed to a higher pressure and more air is

forced into the cylinders. The increased flow of air

into the cylinders allows the fuel to be burnt with

greater efficiency. This produces more power.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

18

KENR9124-01

Systems Operation Section

Crankcase Breather

A wastegate is installed on the turbine housing of

the turbocharger. The wastegate is a valve that

allows exhaust gas to bypass the turbine wheel of

the turbocharger. The operation of the wastegate is

dependent on the pressurized air (boost pressure)

from the turbocharger compressor. The boost

pressure acts on a diaphragm that is spring loaded

in the wastegate actuator which varies the amount of

exhaust gas that flows into the turbine.

The engine crankcase breather is a filtered system.

The crankcase breather system consists of two

main elements, a primary separator in the valve

mechanism cover and a filtered canister that is

mounted on the cylinder head. The gases exit the

engine through the valve mechanism cover. The

gases then pass through the primary separator. The

primary separator removes most of the liquid oil from

the gas. The liquid oil is then returned to the engine.

The wastegate regulator (15) is controlled by the

engine Electronic Control Module (ECM). The

ECM uses inputs from a number of engine sensors

to determine the optimum boost pressure. This

will achieve the best exhaust emissions and fuel

consumption at any given engine operating condition.

The ECM controls the wastegate regulator, that

regulates the boost pressure to the wastegate

actuator.

The gas then passes through the filter element before

exiting to atmosphere in an open breather system

or back to the induction system in a closed breather

system via the breather vent pipe.

Any liquid oil that is captured by the filter drains from

the bottom of the canister. The liquid oil is returned

by the drain pipe that runs from the bottom of the

canister back to the crankcase. A valve connects the

drain pipe to the crankcase. This valve prevents the

bypass of gas past the filter and oil from passing up

the drain pipe.

When higher boost pressure is needed for the

engine performance, a signal is sent from the ECM

to the wastegate regulator. The wastegate regulator

reduces the pressure in the air inlet pipe (14) that

acts upon the diaphragm within the wastegate

actuator (12).

A pressure relief valve is located in the rear of the

canister in the integral mounting bracket. Under

normal operation of the engine, this valve will not

operate. If part of the system becomes blocked the

valve will open at a pressure of 8.5 kPa (1.2 psi). The

open valve will allow gas to bypass the filter and the

pipes for venting.

The spring within the wastegate actuator (12) forces

the wastegate valve that is within the turbine housing

to close via the actuating rod and lever. When the

wastegate valve is closed, more exhaust gas is able

to pass over the turbine wheel. This results in an

increase in turbocharger speed and boost pressure

generation.

The filter element can be accessed by removing

the top cap of the canister. Refer to Operation and

Maintenance Manual, “Engine Crankcase Breather

Element - Replace” for the correct procedure.

When lower boost pressure is needed for the engine

performance, a signal is sent from the ECM to the

wastegate regulator. This causes high pressure in

the air inlet pipe (14) to act on the diaphragm within

the wastegate actuator (12). The actuating rod (13)

acts upon the actuating lever to open the valve in

the wastegate. When the valve in the wastegate is

opened, more exhaust gas from the engine is able to

bypass the turbine wheel. The exhaust gases bypass

the turbine wheel results in a decrease in the speed

of the turbocharger.

NOTICE

The crankcase breather gases are part of the engines

measured emissions output. Any tampering with the

breather system could invalidate the engines emis-

sions compliance.

The shaft that connects the turbine to the compressor

wheel rotates in bearings (4) and (6). The bearings

require oil under pressure for lubrication and cooling.

The oil that flows to the lubricating oil inlet port (5)

passes through the center of the turbocharger which

retains the bearings. The oil exits the turbocharger

from the lubricating oil outlet port (10) and returns

to the oil pan.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

KENR9124-01

19

Systems Operation Section

Valve System Components

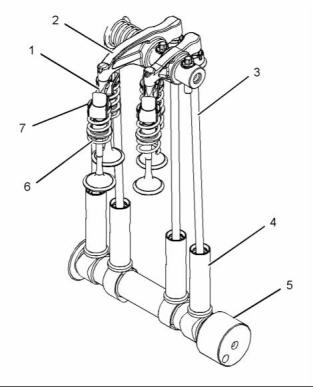

The engine lubricating oil enters the lifter (4) through

a non-return valve. The engine lubricating oil

increases the length of the lifter (4) until all valve lash

is removed. If the engine is stationary for a prolonged

period the valve springs will cause the lifter (4) to

shorten so that when the engine is started engine

valve lash is present for the first few seconds.

After cranking restores oil pressure the lifter (4)

increases in length and removes the valve lash.

When load is removed from a lifter (4) during service

work by the removal of the rocker shaft the lifter

(4) increases in length to the maximum extent.

Refer to Systems Operation, Testing and Adjusting,

“Position the Valve Mechanism Before Maintenance

Procedures” for the correct procedure.

During reassembly of the rocker shaft the engine

must be put into a safe position to avoid engine

damage. After load is imposed on the lifters by

reassembling the rocker assembly, the engine must

be left in safe position for a safe period until the

lifters have reduced to the correct length. Refer to

Disassembly and Assembly, “Rocker Shaft and

Pushrod - Install” for the correct procedure.

Upward movement of the pushrod against rocker arm

(2) results in a downward movement that acts on the

valve bridge (1). This action opens a pair of valves (7)

which compresses the valve springs (6). When the

camshaft (5) has rotated to the peak of the lobe, the

valves are fully open. When the camshaft (5) rotates

further, the two valve springs (6) under compression

start to expand. The valve stems are under tension of

the springs. The stems are pushed upward in order

to maintain contact with the valve bridge (1). The

continued rotation of the camshaft causes the rocker

arm (2), the pushrods (3) and the lifters (4) to move

downward until the lifter reaches the bottom of the

lobe. The valves (7) are now closed. The cycle is

repeated for all the valves on each cylinder.

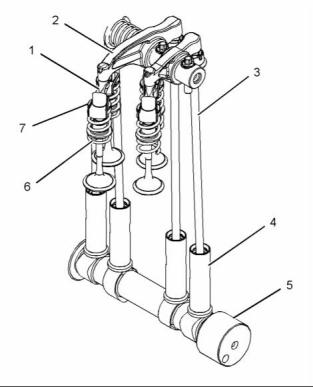

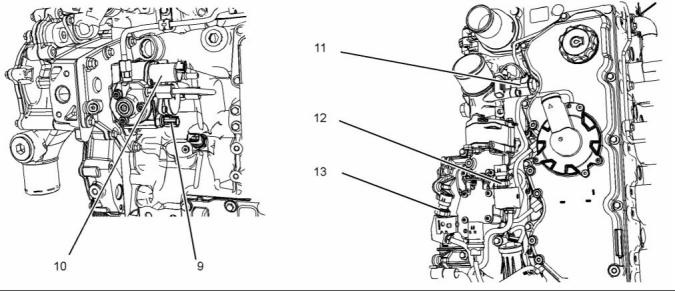

g01924293

Illustration 17

Valve system components

(1) Bridge

(2) Rocker arm

(3) Pushrod

(4) Lifter

(5) Camshaft

(6) Spring

(7) Valve

The valve system components control the flow of

inlet air into the cylinders during engine operation.

The valve system components also control the flow

of exhaust gases out of the cylinders during engine

operation.

The crankshaft gear drives the camshaft gear through

an idler gear. The camshaft (5) must be timed to the

crankshaft in order to get the correct relation between

the piston movement and the valve movement.

The camshaft (5) has two camshaft lobes for each

cylinder. The lobes operate either a pair of inlet

valves or a pair of exhaust valves. As the camshaft

turns, lobes on the camshaft cause the lifter (4) to

move the pushrod (3) up and down.

The lifter (4) incorporates a hydraulic lash adjuster

which removes valve lash from the valve mechanism.

The lifter (4) uses engine lubricating oil to compensate

for wear of system components so that no service

adjustment of valve lash is needed.

This document is printed from SPI². Not for RESALE

![]()

![]()

20

KENR9124-01

Systems Operation Section

i04302992

Air Inlet and Exhaust System

(Series Turbochargers)

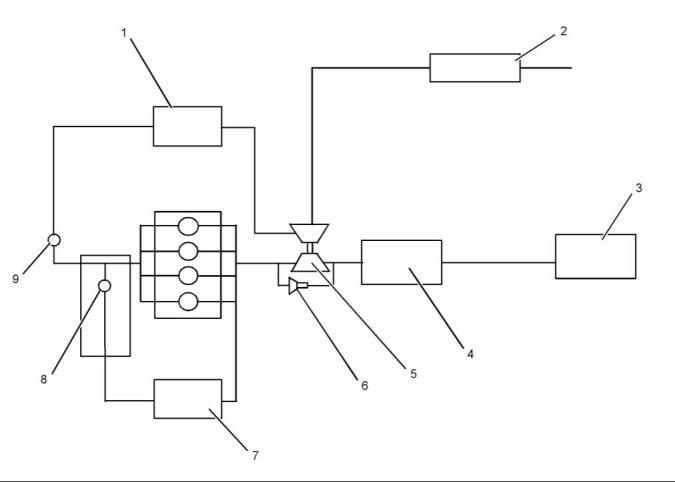

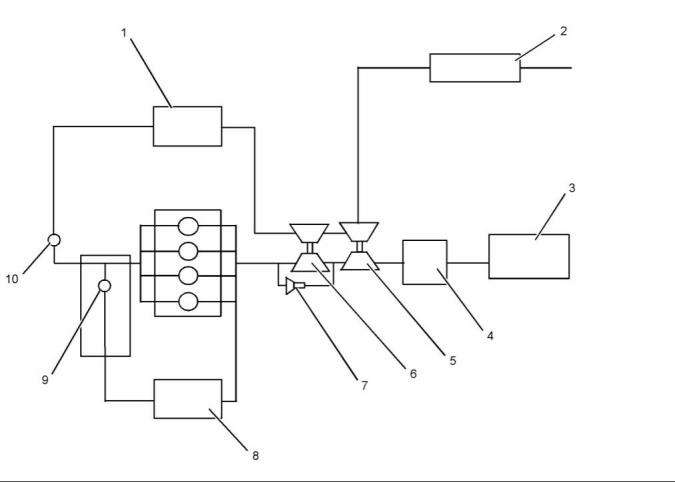

g02467317

Illustration 18

Air inlet and exhaust system

(1) Aftercooler core

(2) Air filter

(3) Diesel particulate filter

(4) Back pressure valve

(5) Low-pressure turbocharger

(6) High-pressure turbocharger

(7) Wastegate actuator

(9) Exhaust gas valve (NRS)

(10) Wastegate regulator

(8) Exhaust cooler (NRS)

The components of the air inlet and exhaust system

control the quality of air and the amount of air that is

available for combustion. The air inlet and exhaust

system consists of the following components:

• Inlet manifold

• Cylinder head, injectors, and glow plugs

• Valves and valve system components

• Piston and cylinder

• Air cleaner

• Exhaust cooler (NRS)

• Exhaust gas valve (NRS)

• Turbochargers

• Exhaust manifold

• Diesel oxidation catalyst

• Diesel particulate filter

• Aftercooler

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9124-01

21

Systems Operation Section

Air is drawn in through the air cleaner into the

air inlet of the low-pressure turbochar, ger by the

low-pressure turbocharger compressor wheel. The

air is compressed to a pressure of about 75 kPa

(11 psi) and heated to about 120° C (248° F). From

the low-pressure turbocharger, the air passes to the

high-pressure turbocharger. The air is compressed

to a pressure of about 220 kPa (32 psi) and heated

to about 240° C (464° F) before the air is forced to

the aftercooler. The air flows through the aftercooler.

The temperature of the compressed air lowers to

about 55° C (131° F). Cooling of the inlet air assists

the combustion efficiency of the engine. Increased

combustion efficiency helps achieve the following

benefits:

From the BC position, the piston moves upward. The

piston moving upward initiates the exhaust stroke.

The exhaust valves open. The exhaust gases are

forced through the open exhaust valves into the

exhaust manifold.

• Lower fuel consumption

• Increased power output

• Reduced NOx emission

• Reduced particulate emission

From the aftercooler, the air flows to the exhaust gas

valve (NRS). A mixture of air and exhaust gas is then

forced into the inlet manifold. Air flow from the inlet

manifold to the cylinders is controlled by inlet valves.

There are two inlet valves and two exhaust valves for

each cylinder. The inlet valves open when the piston

moves down on the intake stroke. When the inlet

valves open, cooled compressed air from the inlet

port is forced into the cylinder. The complete cycle

consists of four strokes:

• Inlet

• Compression

• Power

• Exhaust

On the compression stroke, the piston moves back

up the cylinder and the inlet valves close. The cool

compressed air is compressed further. This additional

compression generates more heat.

Note: If the cold starting system is operating, the

glow plugs will also heat the air in the cylinder.

Just before the piston reaches the top center (TC)

position, the ECM operates the electronic unit

injector. Fuel is injected into the cylinder. The air/fuel

mixture ignites. The ignition of the gases initiates the

power stroke. Both the inlet and the exhaust valves

are closed and the expanding gases force the piston

downward toward the bottom center (BC) position.

This document is printed from SPI². Not for RESALE

![]()

22

KENR9124-01

Systems Operation Section

g02467360

Illustration 19

Typical example

The NOx Reduction System (NRS) operates with

the transfer of the hot exhaust gas from the exhaust

manifold to the exhaust cooler (8). The hot exhaust

gas is cooled in the exhaust cooler (8). The now

cooled exhaust gas passes through the assembly

of the exhaust gas valve.

As the demand for more cooled exhaust gas

increases the electronically controlled valve opens

further. The further opening of the valve increases

the flow of cooled exhaust gas from the exhaust

cooler. As the demand for cooled exhaust gas

decreases, the electronically controlled valve closes.

This decreases the flow of cooled exhaust gas from

the exhaust cooler.

The reed valves that are located in the exhaust gas

valve (NRS) has one main function. The one main

function is to prevent the reverse flow of charge air

from the inlet side of the engine to the exhaust side

of the engine.

Exhaust gases from the exhaust manifold enter the

inlet of the high-pressure turbocharger in order to turn

the high-pressure turbocharger turbine wheel. The

turbine wheel is connected to a shaft that rotates.

The exhaust gases travel from the high-pressure

turbocharger. The exhaust gases then travel through

the duct on the turbine side into the turbine inlet of

the low-pressure turbocharger in order to power

the low-pressure turbocharger. The exhaust gases

pass from the low-pressure turbocharger through the

following components: exhaust outlet, back pressure

valve, Diesel Oxidation Catalyst (DOC), Diesel

Particulate Filter (DPF), and exhaust pipe.

As the electronically controlled valve (9) starts to

open the flow of cooled exhaust gas from the exhaust

cooler (8) mixes with the air flow from the charge air

aftercooler. The mixing of the cooled exhaust gas and

the air flow from the charge air aftercooler reduces

the oxygen content of the gas mixture. This results in

a lower combustion temperature, so decreases the

production of NOx.

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9124-01

23

Systems Operation Section

Turbochargers

g02467380

Illustration 21

g00302786

Illustration 20

Typical example

(12) Wastegate actuator

(13) Actuating lever

(14) Line (boost pressure)

Typical example of a cross section of a turbocharger

(1) Air intake

(2) Compressor housing

(3) Compressor wheel

(4) Bearing

(5) Oil inlet port

(6) Bearing

(7) Turbine housing

(8) Turbine wheel

(9) Exhaust outlet

(10) Oil outlet port

(11) Exhaust inlet

The high-pressure turbocharger is mounted on the

outlet of the exhaust manifold. The low-pressure

turbocharger is mounted on the side of the cylinder

block. The exhaust gas from the exhaust manifold

enters the exhaust inlet (11) and passes through

the turbine housing (7) of the turbocharger. Energy

from the exhaust gas causes the turbine wheel (8) to

rotate. The turbine wheel is connected by a shaft to

the compressor wheel (3).

As the turbine wheel rotates, the compressor

wheel is rotated. This causes the intake air to be

pressurized through the compressor housing (2) of

the turbocharger.

g02151895

Illustration 22

Typical example

(15) Wastegate regulator

When the load on the engine increases, more fuel

is injected into the cylinders. The combustion of

this additional fuel produces more exhaust gases.

The additional exhaust gases cause the turbine and

the compressor wheels of the turbocharger to turn

faster. As the compressor wheel turns faster, air is

compressed to a higher pressure and more air is

forced into the cylinders. The increased flow of air

into the cylinders allows the fuel to be burnt with

greater efficiency. This produces more power.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

24

KENR9124-01

Systems Operation Section

Crankcase Breather

A wastegate is installed on the compressor side

of the turbocharger. The wastegate is a valve that

allows exhaust gas to bypass the turbine wheel of

the turbocharger. The operation of the wastegate is

dependent on the pressurized air (boost pressure)

from the turbocharger compressor. The boost

pressure acts on a diaphragm that is spring loaded

in the wastegate actuator which varies the amount of

exhaust gas that flows into the turbine.

The engine crankcase breather is a filtered system.

The crankcase breather system consists of two

main elements, a primary separator in the valve

mechanism cover and a filtered canister that is

mounted on the cylinder head. The gases exit the

engine through the valve mechanism cover. The

gases then pass through the primary separator. The

primary separator removes most of the liquid oil from

the gas. The liquid oil is then returned to the engine.

The wastegate regulator (15) is controlled by the

engine Electronic Control Module (ECM). The

ECM uses inputs from a number of engine sensors

to determine the optimum boost pressure. This

will achieve the best exhaust emissions and fuel

consumption at any given engine operating condition.

The ECM controls the wastegate regulator, that

regulates the boost pressure to the wastegate

actuator.

The gas then passes through the filter element before

exiting to atmosphere in an open breather system

or back to the induction system in a closed breather

system via the breather vent pipe.

Any liquid oil that is captured by the filter drains from

the bottom of the canister. The liquid oil is returned

by the drain pipe that runs from the bottom of the

canister back to the crankcase. A valve connects the

drain pipe to the crankcase. This valve prevents the

bypass of gas past the filter and oil from passing up

the drain pipe.

When higher boost pressure is needed for the

engine performance, a signal is sent from the ECM

to the wastegate regulator. The wastegate regulator

reduces the pressure in the air inlet pipe (14) that

acts upon the diaphragm within the wastegate

actuator (13).

A pressure control valve is located in the top cap

of the canister. This valve regulates the crankcase

pressure on the closed breather system.

The spring within the wastegate actuator (13) forces

the wastegate valve that is within the turbine housing

to close via the actuating rod and lever. When the

wastegate valve is closed, more exhaust gas is able

to pass over the turbine wheel. This results in an

increase in turbocharger speed and boost pressure

generation.

A pressure relief valve is located in the rear of the

canister in the integral mounting bracket. Under

normal operation of the engine, this valve will not

operate. If part of the system becomes blocked the

valve will open at a pressure of 8.5 kPa (1.2 psi). The

open valve will allow gas to bypass the filter and the

pipes for venting.

When lower boost pressure is needed for the engine

performance, a signal is sent from the ECM to the

wastegate regulator. This causes high pressure in

the air inlet pipe (14) to act on the diaphragm within

the wastegate actuator (13). The actuating rod (12)

acts upon the actuating lever to open the valve in

the wastegate. When the valve in the wastegate is

opened, more exhaust gas from the engine is able to

bypass the turbine wheel. The exhaust gases bypass

the turbine wheel results in a decrease in the speed

of the turbocharger.

The filter element can be accessed by removing

the top cap of the canister. Refer to Operation and

Maintenance Manual, “Engine Crankcase Breather

Element - Replace” for the correct procedure.

NOTICE

The crankcase breather gases are part of the engines

measured emissions output. Any tampering with the

breather system could invalidate the engines emis-

sions compliance.

The shaft that connects the turbine to the compressor

wheel rotates in bearings (4) and (6). The bearings

require oil under pressure for lubrication and cooling.

The oil that flows to the lubricating oil inlet port (5)

passes through the center of the turbocharger which

retains the bearings. The oil exits the turbocharger

from the lubricating oil outlet port (10) and returns

to the oil pan.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

KENR9124-01

25

Systems Operation Section

Valve System Components

The engine lubricating oil enters the lifter (4) through

a non-return valve. The engine lubricating oil

increases the length of the lifter (4) until all valve lash

is removed. If the engine is stationary for a prolonged

period the valve springs will cause the lifter (4) to

shorten so that when the engine is started engine

valve lash is present for the first few seconds.

After cranking restores oil pressure the lifter (4)

increases in length and removes the valve lash.

When load is removed from a lifter (4) during service

work by the removal of the rocker shaft the lifter

(4) increases in length to the maximum extent.

Refer to Systems Operation, Testing and Adjusting,

“Position the Valve Mechanism Before Maintenance

Procedures” for the correct procedure.

During reassembly of the rocker shaft the engine

must be put into a safe position to avoid engine

damage. After load is imposed on the lifters by

reassembling the rocker assembly, the engine must

be left in safe position for a safe period until the

lifters have reduced to the correct length. Refer to

Disassembly and Assembly, “Rocker Shaft and

Pushrod - Install” for the correct procedure.

Upward movement of the pushrod against rocker arm

(2) results in a downward movement that acts on the

valve bridge (1). This action opens a pair of valves (7)

which compresses the valve springs (6). When the

camshaft (5) has rotated to the peak of the lobe, the

valves are fully open. When the camshaft (5) rotates

further, the two valve springs (6) under compression

start to expand. The valve stems are under tension of

the springs. The stems are pushed upward in order

to maintain contact with the valve bridge (1). The

continued rotation of the camshaft causes the rocker

arm (2), the pushrods (3) and the lifters (4) to move

downward until the lifter reaches the bottom of the

lobe. The valves (7) are now closed. The cycle is

repeated for all the valves on each cylinder.

g01924293

Illustration 23

Valve system components

(1) Bridge

(2) Rocker arm

(3) Pushrod

(4) Lifter

(5) Camshaft

(6) Spring

(7) Valve

The valve system components control the flow of

inlet air into the cylinders during engine operation.

The valve system components also control the flow

of exhaust gases out of the cylinders during engine

operation.

i04332330

Clean Emissions Module

The crankshaft gear drives the camshaft gear through

an idler gear. The camshaft (5) must be timed to the

crankshaft in order to get the correct relation between

the piston movement and the valve movement.

To meet current emissions legislation requirements,

a small amount of certain chemical compounds that

are emitted by the engine must not be allowed to

enter the atmosphere. The Clean Emissions Module

(CEM) that is installed to the engine is designed to

convert these chemical compounds into less harmful

compounds.

The camshaft (5) has two camshaft lobes for each

cylinder. The lobes operate either a pair of inlet

valves or a pair of exhaust valves. As the camshaft

turns, lobes on the camshaft cause the lifter (4) to

move the pushrod (3) up and down.

The lifter (4) incorporates a hydraulic lash adjuster

which removes valve lash from the valve mechanism.

The lifter (4) uses engine lubricating oil to compensate

for wear of system components so that no service

adjustment of valve lash is needed.

This document is printed from SPI². Not for RESALE

![]()

![]()

26

KENR9124-01

Systems Operation Section

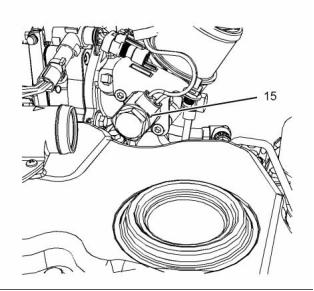

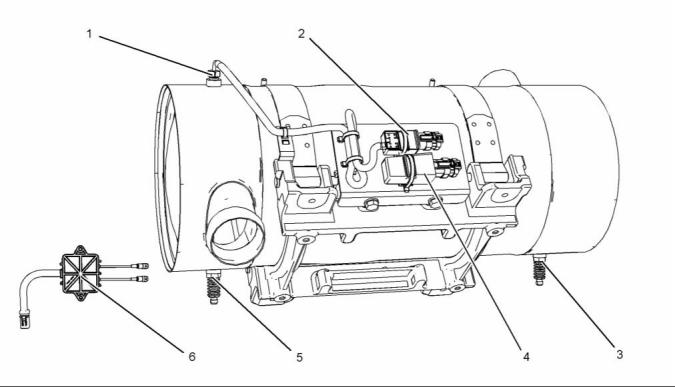

g02384560

Illustration 24

Typical example

(1) Clean emissions module (CEM)

(2) Inlet connection

(3) Outlet connection

(4) Mounting cradle

(5) Flexible exhaust pipe from engine to

CEM

The Clean Emissions Module (CEM) for the engine

consists of the following components.

The rate of accumulation of ash is slow under normal

engine operating conditions. The filter is designed

to contain all the ash that is produced for the life of

the engine.

• Diesel Oxidation Catalyst (DOC)

• Diesel Particulate Filter (DPF)

The engine aftertreatment system is designed to

oxidize the soot in the DPF at the same rate as the

soot is produced by the engine. The oxidization of

the soot will occur when the engine is operating

under normal conditions. The soot in the DPF is

constantly monitored. If the engine is operated in a

way that produces more soot than the oxidized soot,

the engine management system will automatically

activate systems to raise the exhaust temperature.

The raising of the exhaust temperature will ensure

that more soot is oxidized than the soot that is

produced by the engine. The oxidization of more

soot returns the DPF to a reduced level of soot. The

systems are then deactivated when the soot level

has been reduced.

The Diesel Oxidation Catalyst (DOC) oxidizes the

carbon monoxide and the hydrocarbons that are

not burnt in the exhaust gas into carbon dioxide

and water. The Diesel Oxidation Catalyst (DOC) is

a through flow device that will continue to operate

during all normal engine operating conditions.

The Diesel Particulate Filter (DPF) collects all

particulate matter in the exhaust gas.

A flexible exhaust pipe connects the engine to

the Clean Emissions Module (CEM). Refer to

Disassembly and Assembly for the correct procedure

to install the flexible exhaust pipe.

The engine ECM must know how much soot is in the

DPF. Measurement of soot is accomplished through

the following means:

The solid particulate matter that is collected by the

DPF consists of soot (carbon) from incomplete

combustion of the fuel and inorganic ash from the

combustion of any oil in the cylinder.

• Radio frequency measurement across the DPF

• Calculated model based on developed engine out

soot measurements

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9124-01

27

Systems Operation Section

The Electronic Control Module (ECM) uses the soot

measurement information to determine if the engine

operating conditions need to be adjusted in order to

oxidize the soot at an increased rate.

If a replacement Diesel Particulate Filter (DPF) is

required, contact your Perkins distributor.

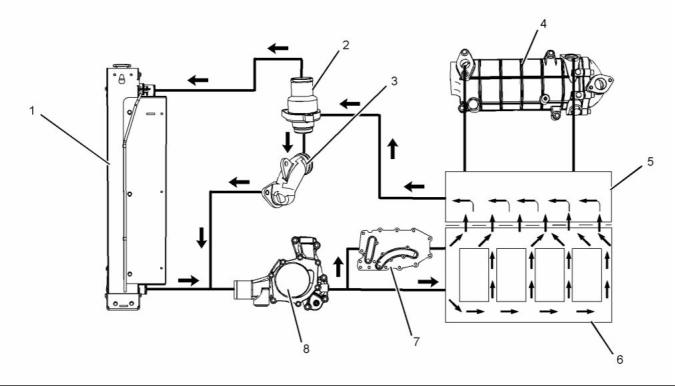

i04135351

Cooling System

Introduction

The cooling system has the following components:

• Radiator

• Water pump

• Cylinder block

• Oil cooler

• Exhaust gas cooler (NRS)

• Cylinder head

• Water temperature regulator

This document is printed from SPI². Not for RESALE

![]()

28

KENR9124-01

Systems Operation Section

Coolant Flow

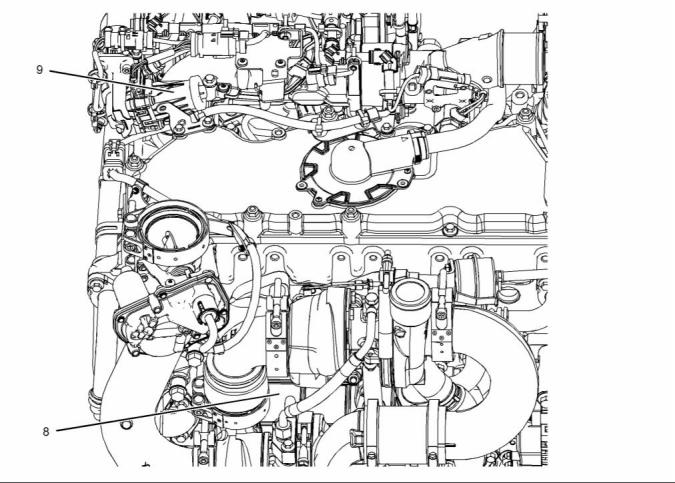

g02332698

Illustration 25

Typical example

(1) Radiator

(4) Exhaust gas cooler (NRS)

(5) Cylinder head

(6) Cylinder block

(8) Water pump

(2) Water temperature regulator and housing

(3) Bypass for the water temperature

regulator

(7) Engine oil cooler

The coolant flows from the bottom of the radiator (1)

to the centrifugal water pump (8). The water pump

(8) is installed on the front of the timing case. The

water pump (8) is driven by a gear. The gear of the

fuel injection pump drives the water pump gear.

Some coolant flows through a cavity in the front of

the cylinder head (5). Some coolant is diverted into

the exhaust gas cooler (4) by a coolant pipe in the

rear of the cylinder head (5). The coolant then flows

out of the exhaust gas cooler (4) to the cavity in the

cylinder head (5).

The water pump (8) contains a rotary seal that uses

the engine coolant as a lubricating medium. This will

ensure that an adequate sealing film is created. The

sealing film is maintained in order to reduce heat

generation. Heat that is generated by the rotating

sealing faces under normal operating conditions

causes a small flow of coolant to be emitted into a

chamber. The water pump (8) pumps the coolant

through a passage in the timing case to the front of

the cylinder block (6).

The coolant then flows into the housing of the water

temperature regulator (2). If the water temperature

regulator (2) is closed, the coolant goes directly

through a bypass (3) to the inlet side of the water

pump. If the water temperature regulator is open, and

the bypass is closed then the coolant flows to the top

of the radiator (1).

The coolant enters a passage in the left side of the

cylinder block (6). Some coolant enters the cylinder

block. Some coolant passes over the element of the

oil cooler (7). The coolant then enters the block (6).

Coolant flows around the outside of the cylinders

then flows from the cylinder block into the cylinder

head (5).

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9124-01

29

Systems Operation Section

The hub of the idler gear is lubricated by oil from the

oil gallery. The timing gears are lubricated by the

splash from the oil.

i03909669

Lubrication System

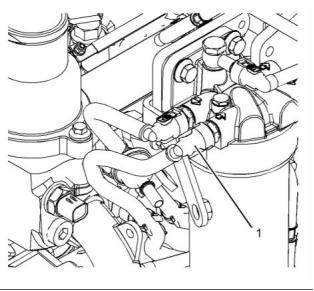

An external line supplies oil to the high-pressure fuel

pump. The oil then flows through a return line into the

timing case and back to the oil pan.

Lubricating oil from the oil pan flows through a

strainer and a pipe to the suction side of the engine

oil pump. Pressure for the lubrication system is

supplied by the oil pump. The crankshaft gear drives

a lower idler gear. The lower idler gear drives the oil

pump gear. The pump has an inner rotor and an outer

rotor. The axis of rotation of the rotors are off-center

relative to each other. There is an interference fit

between the inner rotor and the drive shaft.

Engines have piston cooling jets that are supplied

with oil from the oil gallery. The piston cooling jets

spray lubricating oil on the underside of the pistons in

order to cool the pistons.

i03922889

Electrical System

If a balancer is installed, the engine oil pressure

is provided by an integrated engine oil pump. The

integrated engine oil pump is located in the balancer.

The electrical system is a negative ground system.

The inner rotor has five lobes which mesh with the six

lobes of the outer rotor. When the pump rotates, the

distance increases between the lobes of the outer

rotor and the lobes of the inner rotor in order to create

suction. When the distance decreases between the

lobes, pressure is created.

The charging circuit operates when the engine

is running. The alternator in the charging circuit

produces direct current for the electrical system.

Starting Motor

The lubricating oil flows from the outlet side of the oil

pump through a passage to the oil filter head. The oil

then flows from the oil filter head through a passage

to a plate type oil cooler. The oil cooler is located on

the left side of the cylinder block.

From the oil cooler, the oil returns through a passage

to the oil filter head. The oil then flows through a

bypass valve that permits the lubrication system

to function if the oil filter becomes blocked. Under

normal conditions, the oil then flows to the oil filter.

The oil flows from the oil filter through a passage that

is drilled across the cylinder block to the oil gallery.

The oil gallery is drilled through the total length of

the left side of the cylinder block. If the oil filter is on

the right side of the engine, the oil flows through a

passage that is drilled across the cylinder block to

the pressure gallery.

Lubricating oil from the oil gallery flows through

high-pressure passages to the main bearings of the

crankshaft. Then, the oil flows through the passages

in the crankshaft to the connecting rod bearing

journals. The pistons and the cylinder bores are

lubricated by the splash of oil and the oil mist.

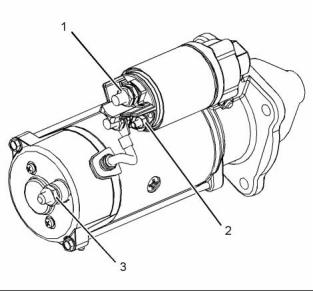

g01964824

Illustration 26

Typical example

12 V 4 kW Starting Motor

(1) Terminal 30 for connection of the battery cable

(2) Terminal 50 for connection of ignition switch

(3) Terminal 31 for connection of the ground

Lubricating oil from the main bearings flows through

passages in the cylinder block to the journals of the

camshaft. Then, the oil flows from the front journal of

the camshaft at a reduced pressure to the cylinder

head. The oil then flows through the center of the

rocker shaft to the rocker arm levers. The valve

stems, the valve springs and the valve lifters are

lubricated by the splash and the oil mist.

This document is printed from SPI². Not for RESALE

![]()

![]()

30

KENR9124-01

Systems Operation Section

Certain higher powered starting motors are designed

with an Integrated Magnetic Switch (IMS). The

Integrated Magnetic Switch (IMS) is activated by the

ignition switch. The solenoid circuit then engages the

starting motor. The benefit of Integrated Magnetic

Switch (IMS) is a lower current in the ignition circuit

that will allow the engine ECM to control ignition

without the use of a relay.

Alternator

The electrical outputs of the alternator have the

following characteristics:

• Three-phase

• Full-wave

• Rectified

The alternator is an electro-mechanical component.

The alternator is driven by a belt from the crankshaft

pulley. The alternator charges the storage battery

during the engine operation.

g01964833

Illustration 27

Typical example

24 V 5.5 kW Starting Motor

(4) Terminal 30 for connection of the battery cable

(5) Integrated Magnetic Switch (IMS)

(6) Terminal 50 for connection of ignition switch

(7) Terminal 31 for connection of the ground

The alternator is cooled by an external fan which is

mounted behind the pulley. The fan may be mounted

internally. The fan forces air through the holes in the

front of the alternator. The air exits through the holes

in the back of the alternator.

The starting motor turns the engine via a gear on the

engine flywheel. The starting motor speed must be

high enough in order to initiate a sustained operation

of the fuel ignition in the cylinders.

The alternator converts the mechanical energy and

the magnetic field into alternating current and voltage.

This conversion is done by rotating a direct current

electromagnetic field on the inside of a three-phase

stator. The electromagnetic field is generated by

electrical current flowing through a rotor. The stator

generates alternating current and voltage.

The starting motor consists of the main armature and

a solenoid. The solenoid is a relay with two windings

Pull-In (PI) and Hold-In (HI). Upon activation of

ignition switch, both windings move the iron core

by electromagnets. The linkage from the iron core

acts to move the pinion toward the flywheel ring

gear for engagement. Upon complete engagement,

the solenoid completes the high current circuit that

supplies electric power to the main armature in order

to provide rotation. During cranking of the engine,

only the Hold-In (HI) winding is active.

The alternating current is changed to direct current

by a three-phase, full-wave rectifier. Direct current

flows to the output terminal of the alternator. The

direct current is used for the charging process.

A regulator is installed on the rear end of the

alternator. Two brushes conduct current through two

slip rings. The current then flows to the rotor field. A

capacitor protects the rectifier from high voltages.

The ignition switch is deactivated once the desired

engine speed has been achieved. The circuit is

disconnected. The armature will stop rotating. Return

springs that are located on the shafts and the

solenoid will disengage the pinion from flywheel ring

gear back to the rest position.

The alternator is connected to the battery for charging

and machine load requirements. A warning lamp can

be connected via the ignition switch. This wiring is

optional.

The armature of the starting motor and the

mechanical transmissions may be damaged if the

increases in the speed of the engine are greater

than the pinion of the starting motor. Damage may

occur when the engine is started or after the engine

is started. An overrunning clutch prevents damage to

the armature of the starting motor and mechanical

transmissions.

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9124-01

31

Systems Operation Section

Refueling

i04103311

Cleanliness of Fuel System

Components

In order to refuel the diesel fuel tank, the refueling

pump and the fuel tank cap assembly must be clean

and free from dirt and debris. Refueling should take

place only when the ambient conditions are free from

dust, wind, and rain.

Cleanliness of the Engine

Only use fuel that is free from contamination. Ultra

Low Sulfur Diesel (ULSD) must be used. The content

of sulfur in Ultra Low Sulfur Diesel (ULSD) fuel must

be below 15 PPM 0.0015%.

NOTICE

It is important to maintain extreme cleanliness when

working on the fuel system, since even tiny particles

can cause engine or fuel system problems.

Biodiesel may be used. The neat biodiesel must

conform to the latest “EN14214 or ASTM D6751”

(in the USA). The biodiesel can only be blended in

mixture of up to 20% by volume in acceptable mineral

diesel fuel meeting latest edition of “EN590 or ASTM

D975 S15” designation.

The entire engine should be washed with a

high-pressure water system. Washing the engine will

remove dirt and loose debris before a repair on the

fuel system is started. Ensure that no high-pressure

water is directed at the seals for the injectors.

In United States, Biodiesel blends of B6 to B20 must

meet the requirements listed in the latest edition of

“ASTM D7467” (B6 to B20) and must be of an API

gravity of 30-45.

Environment

When possible, the service area should be positively

pressurized. Ensure that the components are not

exposed to contamination from airborne dirt and

debris. When a component is removed from the

system, the exposed fuel connections must be

closed off immediately with suitable sealing plugs.

The sealing plugs should only be removed when

the component is reconnected. The sealing plugs

must not be reused. Dispose of the sealing plugs

immediately after use. Contact your nearest Perkins

distributor in order to obtain the correct sealing plugs.

For more information, refer to Operation and

Maintenance Manual, “Fluid Recommendations”.

i04135694

Fuel Injection

Introduction

New Components

High-pressure lines are not reusable. New

high-pressure lines are manufactured for installation

in one position only. When a high-pressure line is

replaced, do not bend or distort the new line. Internal

damage to the pipe may cause metallic particles to

be introduced to the fuel.

All new fuel filters, high-pressure lines, tube

assemblies, and components are supplied with

sealing plugs. These sealing plugs should only be

removed in order to install the new part. If the new

component is not supplied with sealing plugs then

the component should not be used.

The technician must wear suitable rubber gloves.

The rubber gloves should be disposed of immediately

after completion of the repair in order to prevent

contamination of the system.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

32

KENR9124-01

Systems Operation Section

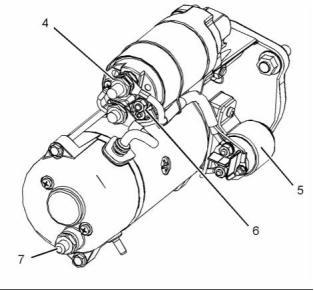

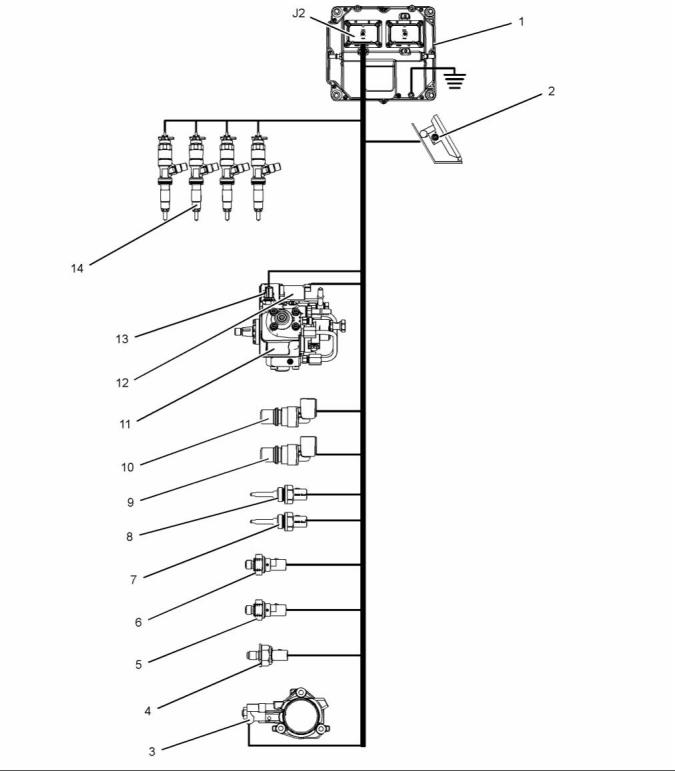

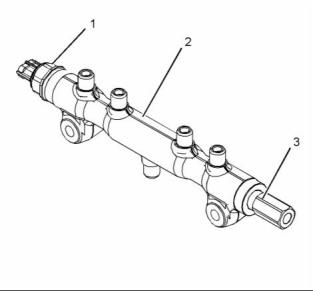

g02450139

Illustration 28

Typical example

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9124-01

33

Systems Operation Section

(1) Fuel strainer

(5) Secondary fuel filter

(6) Fuel Injection Pump

(7) Inlet pressure regulator

(8) Fuel manifold (rail)

(9) Pressure relief valve

(2) Electric transfer pump

(3) Primary fuel filter

(4) ECM that is fuel cooled.

(10) Electronic unit injector

(11) Fuel cooler (optional)

(A) Fuel tank

Fuel is drawn from the fuel tank through a fuel

strainer to an external electric transfer pump. The

fuel then flows to the 10 micron primary fuel filter and

a water separator.

The fuel may flow to a fuel cooled ECM. The fuel

then flows to a 4 micron secondary fuel filter.

The fuel flows from the secondary fuel filter to a

pressure regulator. A pressure regulator that is

installed in the low-pressure fuel system controls the

fuel pressure to the fuel injection pump. The pressure

regulator regulates the fuel at a pressure of 150 kPa

(22 psi) when the engine is at idle speed.

From the pressure regulator, the fuel flows to the fuel

injection pump. The fuel is pumped at an increased

pressure of 200 MPa (29000 psi) to the fuel manifold

(rail).

Fuel that has too high a pressure from the fuel

manifold (rail) returns through the pressure relief

valve to the return line. Fuel that is leak off from the

electronic unit injectors flows to the return line. The

fuel may then flow through an optional fuel cooler on

the way back to the fuel tank.

This document is printed from SPI². Not for RESALE

![]()

34

KENR9124-01

Systems Operation Section

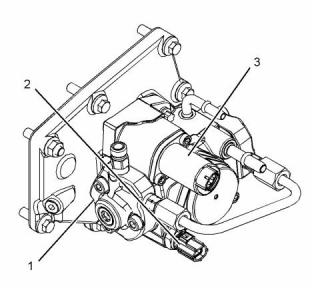

High Pressure Fuel System

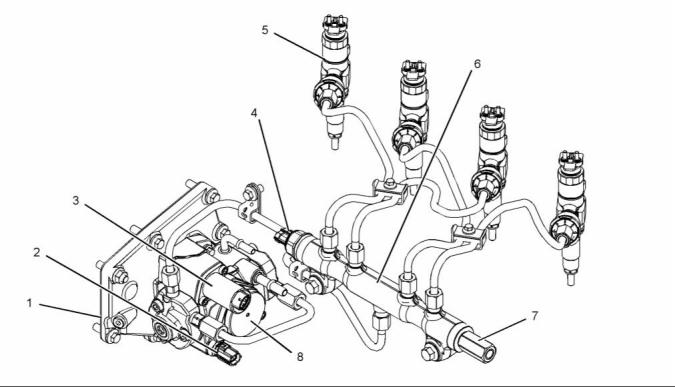

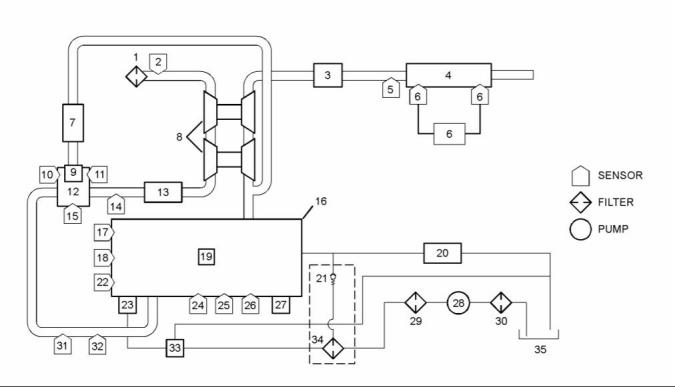

g02450116

Illustration 29

Typical example

(1) Fuel injection pump

(2) Fuel temperature sensor

(3) Suction control valve for the fuel injection

pump

(4) Fuel pressure sensor

(5) Electronic unit injector

(6) Fuel manifold (rail)

(7) Pressure relief valve

(8) Fuel transfer pump

The fuel injection pump (1) feeds fuel to the

• Fuel transfer pump

high-pressure fuel manifold (rail) (6). The fuel is

at a pressure of 200 MPa (29000 psi). A pressure

sensor (4) in the high-pressure fuel manifold (rail) (6)

monitors the fuel pressure in the high-pressure fuel

manifold (rail) (6). The ECM controls a suction control

valve (3) in the fuel injection pump (1) in order to

maintain the actual pressure in the high-pressure fuel

manifold (6) at the desired level. The high-pressure

fuel is continuously available at each injector. The

ECM determines the correct time for activation of the

correct electronic unit injector (5) which allows fuel

to be injected into the cylinder. The leakoff fuel from

each injector passes into a drilling which runs along

the inside of the cylinder head. A pipe is connected

to the rear of the cylinder head in order to return the

leakoff fuel to the fuel tank.

• Secondary fuel filter

• Fuel injection pump

• Fuel injectors

• Fuel manifold

• Pressure relief valve

• Fuel pressure sensor

• Fuel temperature sensor

The following list contains examples of both

service and repairs when you must prime the

system:

Components of the Fuel Injection System

• A fuel filter is changed.

The fuel injection system has the following

mechanical components:

• A low-pressure fuel line is replaced.

• The fuel injection pump is replaced.

• The ECM is replaced.

• Primary filter/water separator

• Electric transfer pump

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9124-01

35

Systems Operation Section

Secondary Fuel Filter

For the correct procedure to prime the fuel system,

refer to Systems Operation, Testing and Adjusting,

“Fuel System - Prime”.

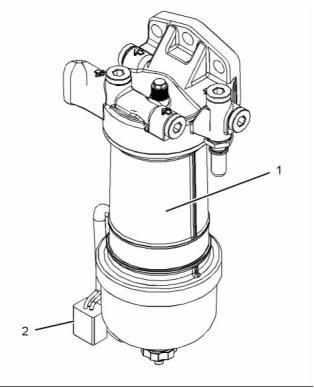

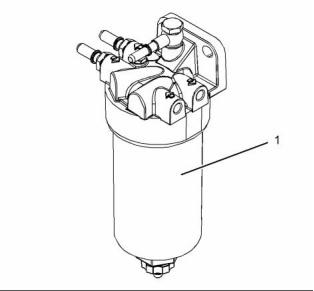

Primary Filter/Water Separator

g02214536

Illustration 31

Typical example

The secondary fuel filter (1) is located after the

primary fuel filter. The secondary fuel filter (1)

provides a 4 micron filtration level.

Fuel Pump Assembly

g02214535

Illustration 30

Typical example

The primary filter/water separator (1) is located

between the electric lift pump and the secondary fuel

filter. The primary filter/water separator (1) provides a

10 micron filtration level.

The primary filter/water separator can either be

engine mounted or supplied loose. The primary