產(chǎn)品中心

美國強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢圖冊

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國道依茨 韓國大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

珀金斯Perkins2206-E13操作保養(yǎng)維修

詳細(xì)描述

Operation and

Maintenance

Manual

2206-E13 Industrial Engine

TGB (Engine)

TGD (Engine)

TGF (Engine)

Electronic Control Module 9

The ECM controls the engine operating parameters

through the software within the ECM and the inputs

from the various sensors. The software within the

ECM can be changed by installing a new flash file.

The flash file defines the following characteristics

of the engine:Engine power, Torque curves, Engine

speed (rpm), Engine Noise, Smoke, and Emissions.

This document has been printed from SPI². Not for Resale

![]()

SEBU8337

29

Operation Section

Engine Diagnostics

Engine Diagnostics

i02651197

Engine Operation with Active

Diagnostic Codes

i02784187

Self-Diagnostics

If a diagnostic lamp illuminates during normal engine

operation, the system has identified a situation that is

not within the specification. Use the electronic service

tool to check the active diagnostic codes.

The electronic control module has some

self-diagnostic ability. When an electronic problem

with an input or an output is detected, a diagnostic

code is generated. This indicates the specific problem

with the circuitry.

The active diagnostic code should be investigated.

The cause of the problem should be corrected as

soon as possible. If the cause of the active diagnostic

code is repaired and there is only one active

diagnostic code, the diagnostic lamp will turn off.

A diagnostic code which represents a problem that

currently exists is called an active code.

A diagnostic code that is stored in memory is called

a logged code. Always service active codes prior to

servicing logged codes. Logged codes may indicate

intermittent problems.

Operation of the engine and performance of the

engine can be limited as a result of the active

diagnostic code that is generated. Acceleration rates

may be significantly slower and power outputs may

be automatically reduced. Refer to Troubleshooting

, “Troubleshooting with a Diagnostic Code” for more

information on the relationship between each active

diagnostic code and the possible effect on engine

performance.

Logged codes may not indicate that a repair is

needed. The problems may have been repaired since

the logging of the code. Logged codes may be helpful

to troubleshoot intermittent problems.

i02572812

i02784585

Engine Operation with

Diagnostic Lamp

Intermittent Diagnostic Codes

The “DIAGNOSTIC” lamp is used to indicate the

existence of an active fault.

If a diagnostic lamp illuminates during normal engine

operation and the diagnostic lamp shuts OFF, an

intermittent fault may have occurred. If a fault has

occurred, the fault will be logged into the memory of

the Electronic Control Module (ECM).

A fault diagnostic code will remain active until the

problem is repaired.

i02784192

Fault Logging

In most cases, it is not necessary to stop the engine

because of an intermittent code. However, the

operator should retrieve the logged fault codes

and the operator should reference the appropriate

information in order to identify the nature of the fault.

The operator should log any observation that could

have caused the lamp to light.

The system provides the capability of Fault Logging.

When the Electronic Control Module (ECM)

generates an active diagnostic code, the code will

be logged in the memory of the ECM. The Perkins

electronic service tool can retrieve codes that have

been logged. The codes that have been logged can

be cleared with the Perkins electronic service tool.

The codes that have been logged in the memory

of the ECM will be automatically cleared from the

memory after 100 hours.

• Low power

• Limits of the engine speed

• Excessive smoke, etc

This information can be useful to help troubleshoot

the situation. The information can also be used for

future reference. For more information on diagnostic

codes, refer to the Troubleshooting guide for this

engine.

This document has been printed from SPI². Not for Resale

![]()

30

SEBU8337

Operation Section

Engine Starting

Engine Starting

i02583442

Starting the Engine

i02773196

Before Starting Engine

Note: Do not adjust the engine speed control during

start-up. The electronic control module (ECM) will

control the engine speed during start-up.

Before the engine is started, perform the required

daily maintenance and any other periodic

maintenance that is due. Refer to the Operation

and Maintenance Manual, “Maintenance Interval

Schedule” for more information.

New engines

Prime the turbocharger. This can be achieved by

cranking the engine briefly with no fuel.

• Open the fuel supply valve (if equipped).

If necessary, stop a new engine if an overspeed

condition occurs. If necessary, press the Emergency

Stop button.

NOTICE

All valves in the fuel return line must be open before

and during engine operation to help prevent high fuel

pressure. High fuel pressure may cause filter housing

failure or other damage.

Starting the Engine

1. Move the ignition switch to the ON position. If a

system fault is indicated, investigate the cause. If

necessary, use the Perkins electronic service tool.

If the engine has not been started for several weeks,

fuel may have drained from the fuel system. Air

may have entered the filter housing. Also, when fuel

filters have been changed, some air pockets will be

trapped in the engine. In these instances, prime the

fuel system. Refer to the Operation and Maintenance

Manual, “Fuel System - Prime” for more information

on priming the fuel system.

2. Push the start button or turn the keyswitch to the

START position in order to crank the engine.

3. If the engine fails to start within 30 seconds,

release the start button or the ignition switch. Wait

for 30 seconds in order to allow the starting motor

to cool before attempting to start the engine again.

Note: A system fault may be indicated after the

engine is started. If this occurs the ECM has detected

a problem with the system. If necessary, use the

Perkins Service Tool to investigate the problem.

Engine exhaust contains products of combustion

which may be harmful to your health. Always start

and operate the engine in a well ventilated area

and, if in an enclosed area, vent the exhaust to the

outside.

Note: Oil pressure should rise within 15 seconds

after the engine starts. The engine electronic controls

monitor the engine oil pressure. The electronic

controls will stop the engine if the oil pressure is

below normal.

• Do not start the engine or move any of the controls

if there is a “DO NOT OPERATE” warning tag or

similar warning tag attached to the start switch or

to the controls.

4. When possible, allow the engine to run at no load

for approximately three minutes. Run the engine

at no load until the water temperature gauge

has started to rise. Check all gauges during the

warm-up period.

• Reset all of the shutoffs or alarm components (if

equipped).

• Ensure that any equipment that is driven by the

engine has been disengaged from the engine.

Minimize electrical loads or remove any electrical

loads.

• Ensure that the coolant level is correct.

• Ensure that the engine oil level is correct.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

SEBU8337

31

Operation Section

Engine Starting

i02815193

4. Operate the engine at no load until all the coolant

temperature starts to rise. Check the gauges

during the warm-up period.

Cold Weather Starting

Note: The oil pressures and fuel pressures should

be in the normal range on the instrument panel. Do

not apply a load to the engine until the oil pressure

gauge indicates at least normal pressure. Inspect the

engine for leaks and/or unusual noises.

Do not use aerosol types of starting aids such as

ether. Such use could result in an explosion and

personal injury.

Note: After the ECM has completed the cold mode,

cold mode cannot be enabled again until the ECM is

switched OFF.

The engine will start at a temperature of −10 °C

(14 °F). The ability to start at temperatures below

10 °C (50 °F) will improve by the use of a cylinder

block coolant heater or a device which heats the

crankcase oil. This will help to reduce white smoke

and misfires when the engine is started in cold

weather.

Note: Do not attempt to restart the engine until the

engine has completely stopped.

i02428473

Starting with Jump Start

Cables

If the engine has not been run for several weeks, fuel

may have drained. Air may have moved into the filter

housing. Also, when fuel filters have been changed,

some air will be left in the filter housing. Refer to

Operation and Maintenance Manual, “Fuel System -

Prime” in order to remove air from the fuel system.

Do not use jump start cables in order to start the

engine. Charge the batteries or replace the batteries.

Refer to Operation and Maintenance Manual,

“Battery - Replace”.

Use the procedure that follows for cold weather

starting.

NOTICE

Do not engage the starting motor when flywheel is

turning. Do not start the engine under load.

If the engine fails to start within 30 seconds, release

the starter switch or button and wait thirty seconds to

allow the starting motor to cool before attempting to

start the engine again.

1. If equipped, press the start button. If equipped,

turn the keyswitch to the START position in order

to engage the electric starting motor and crank

the engine.

2. Repeat step 1 three times if the engine fails to

start.

3. If the engine fails to start, investigate the problem.

Use the Perkins electronic service tool. A system

fault may be indicated after the engine is started. If

this occurs the ECM has detected a problem with

the system. Investigate the cause of the problem.

Use the Perkins electronic service tool.

Note: Oil pressure should rise within 15 seconds

after the engine starts. The electronic engine controls

monitor the oil pressure. The electronic controls will

stop the engine if the oil pressure is below normal.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

32

SEBU8337

Operation Section

Engine Starting

i01646248

After Starting Engine

Note: In temperatures from 0 to 60°C (32 to 140°F),

the warm-up time is approximately three minutes. In

temperatures below 0°C (32°F), additional warm-up

time may be required.

Note: Ensure that the self test for the monitoring

system (if equipped) is completed before operating

the engine under load.

When the engine idles during warm-up, observe the

following conditions:

• Check for any fluid or for any air leaks at idle rpm

and at one-half full rpm (no load on the engine)

before operating the engine under load. This is not

possible in some applications.

• Operate the engine at low idle until all systems

achieve operating temperatures. Check all gauges

during the warm-up period.

Note: Gauge readings should be observed and

the data should be recorded frequently while the

engine is operating. Comparing the data over time

will help to determine normal readings for each

gauge. Comparing data over time will also help

detect abnormal operating developments. Significant

changes in the readings should be investigated.

This document has been printed from SPI². Not for Resale

![]()

SEBU8337

33

Operation Section

Engine Operation

Engine Operation

i02583385

Fuel Conservation Practices

i02578030

Engine Operation

The efficiency of the engine can affect the fuel

economy. Perkins design and technology in

manufacturing provides maximum fuel efficiency in

all applications. Follow the recommended procedures

in order to attain optimum performance for the life

of the engine.

Correct operation and maintenance are key factors

in obtaining the maximum life and economy of

the engine. If the directions in the Operation and

Maintenance Manual are followed, costs can be

minimized and engine service life can be maximized.

• Avoid spilling fuel.

Gauge readings should be observed and the data

should be recorded frequently while the engine

is operating. Comparing the data over time will

help to determine normal readings for each gauge.

Comparing data over time will also help detect

abnormal operating developments. Significant

changes in the readings should be investigated.

Fuel expands when the fuel is warmed up. The fuel

may overflow from the fuel tank. Inspect fuel lines for

leaks. Repair the fuel lines, as needed.

• Be aware of the properties of the different fuels.

Use only the recommended fuels.

• Avoid unnecessary operation at no load.

Shut off the engine instead of operating the engine

at no load for long periods of time.

• Observe the service indicator for the air cleaner

frequently, if equipped. Keep the air cleaner

elements clean.

• Maintain a good electrical system.

One bad battery cell will overwork the alternator. This

will consume excess power and excess fuel.

• Ensure that the belts are properly adjusted. The

belts should be in good condition.

• Ensure that all of the connections of the hoses are

tight. The connections should not leak.

• Ensure that the driven equipment is in good

working order.

• Cold engines consume excess fuel. Keep cooling

system components clean and keep cooling

system components in good repair. Never operate

the engine without water temperature regulators.

All of these items will help maintain operating

temperatures.

This document has been printed from SPI². Not for Resale

![]()

34

SEBU8337

Operation Section

Engine Stopping

Engine Stopping

i02583411

After Stopping Engine

i02572824

Manual Stop Procedure

Note: Before you check the engine oil, do not operate

the engine for at least 10 minutes in order to allow

the engine oil to return to the oil pan.

Stopping the Engine

• Check the crankcase oil level. Maintain the oil level

between the “LOW” mark and the “HIGH” mark on

the oil level gauge.

NOTICE

Stopping the engine immediately after it has been

working under load, can result in overheating and ac-

celerated wear of the engine components.

Note: Only use oil that is recommended in

this Operation and Maintenance Manual, “Fluid

Recommendations”. Failure to use the recommended

oil may result in engine damage.

Avoid accelerating the engine prior to shutting it down.

Avoiding hot engine shutdowns will maximize tur-

bocharger shaft and bearing life.

• If necessary, perform minor adjustments. Repair

any leaks and tighten any loose bolts.

• Note the service hour meter reading. Perform

the maintenance that is in the Operation and

Maintenance Manual, “Maintenance Interval

Schedule”.

Note: Individual applications will have different

control systems. Ensure that the shutoff procedures

are understood. Use the following general guidelines

in order to stop the engine.

• Fill the fuel tank in order to help prevent

accumulation of moisture in the fuel. Do not overfill

the fuel tank.

1. Remove the load from the engine. Allow the

engine to run under no load conditions for five

minutes in order to cool the engine.

• Allow the engine to cool. Check the coolant level.

Maintain the cooling system at 13 mm (0.5 inch)

from the bottom of the pipe for filling.

2. Stop the engine after the cool down period

according to the shutoff system on the engine and

turn the ignition keyswitch to the OFF position.

If necessary, refer to the instructions that are

provided by the OEM.

Note: Only use coolant that is recommended in

this Operation and Maintenance Manual, “Fluid

Recommendations”. Failure to use the recommended

oil may result in engine damage.

Emergency Stopping

• If freezing temperatures are expected, check

the coolant for proper antifreeze protection. The

cooling system must be protected against freezing

to the lowest expected outside temperature. Add

the proper coolant/water mixture, if necessary.

NOTICE

Emergency shutoff controls are for EMERGENCY use

ONLY. DO NOT use emergency shutoff devices or

controls for normal stopping procedure.

• Perform all required periodic maintenance on all

driven equipment. This maintenance is outlined in

the instructions from the OEM.

The OEM may have equipped the application with

an emergency stop button. For more information

about the emergency stop button, refer to the OEM

information.

Ensure that any components for the external system

that support the engine operation are secured after

the engine is stopped.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

SEBU8337

35

Operation Section

Cold Weather Operation

Cold Weather Operation

Personal injury or property damage can result

from alcohol or starting fluids.

i02581613

Cold Weather Operation

Alcohol or starting fluids are highly flammable and

toxic and if improperly stored could result in injury

or property damage.

Perkins Diesel Engines can operate effectively in

cold weather. During cold weather, the starting and

the operation of the diesel engine is dependent on

the following items:

Do not use aerosol types of starting aids such as

ether. Such use could result in an explosion and

personal injury.

• The type of fuel that is used

• The viscosity of the engine oil

• Optional Cold starting aid

• Battery condition

Viscosity of the Engine Lubrication

Oil

Correct engine oil viscosity is essential. Oil viscosity

affects the amount of torque that is needed

to crank the engine. Refer to Operation and

Maintenance Manual, “Fluid Recommendations” for

the recommended viscosity of oil.

The operation and maintenance of an engine in

freezing temperatures is complex . This is because

of the following conditions:

• Weather conditions

• Engine applications

Recommendations for the Coolant

Provide cooling system protection for the lowest

expected outside temperature. Refer to this Operation

and Maintenance Manual, “Fluid Recommendations”

for the recommended coolant mixture.

Recommendations from your Perkins distributor are

based on past proven practices. The information that

is contained in this section provides guidelines for

cold weather operation.

In cold weather, check the coolant often for the

correct glycol concentration in order to ensure

adequate freeze protection.

Hints for Cold Weather Operation

• If the engine will start, operate the engine until a

minimum operating temperature of 81 °C (177.8 °F)

is achieved. Achieving operating temperature will

help prevent the intake valves and exhaust valves

from sticking.

Engine Block Heaters

Engine block heaters (if equipped) heat the

engine jacket water that surrounds the combustion

chambers. This provides the following functions:

• The cooling system and the lubrication system

for the engine do not lose heat immediately upon

shutdown. This means that an engine can be shut

down for a period of time and the engine can still

have the ability to start readily.

• Startability is improved.

An electric block heater can be activated once

the engine is stopped. An effective block heater is

typically a 1250/1500 W unit. Consult your Perkins

distributor for more information.

• Install the correct specification of engine lubricant

before the beginning of cold weather.

• Check all rubber parts (hoses, fan drive belts, etc)

weekly.

• Check all electrical wiring and connections for any

fraying or damaged insulation.

• Keep all batteries fully charged and warm.

• Check the air cleaners and the air intake daily.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

36

SEBU8337

Operation Section

Cold Weather Operation

i02576035

• A lower energy per unit volume of fuel

Fuel and the Effect from Cold

Weather

Note: Group 3 fuels reduce the life of the engine. The

use of Group 3 fuels is not covered by the Perkins

warranty.

Group 3 fuels include Low Temperature Fuels and

Aviation Kerosene Fuels.

Note: Only use grades of fuel that are recommended

by Perkins. Refer to this Operation and Maintenance

Manual, “Fluid Recommendations”.

Special fuels include Biofuel.

The cloud point is a temperature that allows wax

crystals to form in the fuel. These crystals can cause

the fuel filters to plug.

The following fuels can be used in this series of

engine.

• Group 1

The pour point is the temperature when diesel fuel

will thicken. The diesel fuel becomes more resistant

to flow through fuel lines, fuel filters,and fuel pumps.

• Group 2

• Group 3

Be aware of these facts when diesel fuel is

purchased. Consider the average ambient air

temperature for the engine’s application. Engines

that are fueled in one climate may not operate well if

the engines are moved to another climate. Problems

can result due to changes in temperature.

• Special Fuels

Perkins prefer only Group 1 and Group 2 fuels for

use in this series of engines.

Group 1 fuels are the preferred Group of Fuels for

general use by Perkins. Group 1 fuels maximize

engine life and engine performance. Group 1 fuels

are usually less available than Group 2 fuels.

Frequently, Group 1 fuels are not available in colder

climates during the winter.

Before troubleshooting for low power or for poor

performance in the winter, check the fuel for waxing.

Low temperature fuels may be available for engine

operation at temperatures below 0 °C (32 °F). These

fuels limit the formation of wax in the fuel at low

temperatures.

Note: Group 2 fuels must have a maximum wear

scar of 650 micrometers (HFRR to ISO 12156-1).

For more information on cold weather operation, refer

to the Operation and Maintenance Manual, “Cold

Weather Operation and Fuel Related Components in

Cold Weather”.

Group 2 fuels are considered acceptable for issues

of warranty. This group of fuels may reduce the life

of the engine, the engine’s maximum power, and the

engine’s fuel efficiency.

When Group 2 diesel fuels are used the following

components provide a means of minimizing problems

in cold weather:

• Glow plugs (if equipped)

• Engine coolant heaters, which may be an OEM

option

• Fuel heaters, which may be an OEM option

• Fuel line insulation, which may be an OEM option

There are three major differences between Group

1 fuels and Group 2 fuels. Group 1 fuels have the

following different characteristics to Group 2 fuels.

• A lower cloud point

• A lower pour point

This document has been printed from SPI². Not for Resale

![]()

SEBU8337

37

Operation Section

Cold Weather Operation

i02583420

Fuel Related Components in

Cold Weather

Fuel Tanks

Condensation can form in partially filled fuel tanks.

Top off the fuel tanks after you operate the engine.

Fuel tanks should contain some provision for draining

water and sediment from the bottom of the tanks.

Some fuel tanks use supply pipes that allow water

and sediment to settle below the end of the fuel

supply pipe.

Some fuel tanks use supply lines that take fuel

directly from the bottom of the tank. If the engine is

equipped with this system, regular maintenance of

the fuel system filter is important.

Drain the water and sediment from any fuel storage

tank at the following intervals: weekly, oil changes,

and refueling of the fuel tank. This will help prevent

water and/or sediment from being pumped from the

fuel storage tank and into the engine fuel tank.

Fuel Filters

A primary fuel filter is installed between the fuel

tank and the engine fuel inlet. After you change

the fuel filter, always prime the fuel system in order

to remove air bubbles from the fuel system. Refer

to the Operation and Maintenance Manual in the

Maintenance Section for more information on priming

the fuel system.

The micron rating and the location of a primary fuel

filter is important in cold weather operation. The

primary fuel filter and the fuel supply line are the most

common components that are affected by cold fuel.

This document has been printed from SPI². Not for Resale

![]()

38

SEBU8337

Maintenance Section

Refill Capacities

Maintenance Section

i03040206

Fluid Recommendations

Refill Capacities

Cooling System Specifications

i02793514

Refill Capacities

General Coolant Information

NOTICE

Never add coolant to an overheated engine. Engine

damage could result. Allow the engine to cool first.

Lubrication System

The refill capacities for the engine crankcase

NOTICE

reflect the approximate capacity of the crankcase

or sump plus standard oil filters. Auxiliary oil filter

systems will require additional oil. Refer to the OEM

specifications for the capacity of the auxiliary oil filter.

Refer to the Operation and Maintenance Manual,

“Maintenance Section” for more information on

Lubricant Specifications.

If the engine is to be stored in, or shipped to an area

with below freezing temperatures, the cooling system

must be either protected to the lowest outside temper-

ature or drained completely to prevent damage.

NOTICE

Frequently check the specific gravity of the coolant for

proper freeze protection or for anti-boil protection.

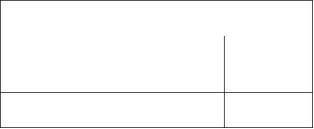

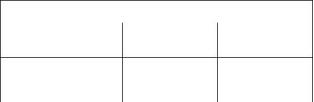

Table 3

Engine

Refill Capacities

Clean the cooling system for the following reasons:

• Contamination of the cooling system

• Overheating of the engine

Compartment or System

Crankcase Oil Sump

Maximum

(1)

40 L (8.8 Imp gal)

(1) These values are the approximate capacities for the crankcase

oil sump (aluminum) which includes the standard factory

installed oil filters. Engines with auxiliary oil filters will require

additional oil. Refer to the OEM specifications for the capacity

of the auxiliary oil filter.

• Foaming of the coolant

NOTICE

Cooling System

Never operate an engine without water temperature

regulators in the cooling system. Water temperature

regulators help to maintain the engine coolant at the

proper operating temperature. Cooling system prob-

lems can develop without water temperature regula-

tors.

Refer to the OEM specifications for the External

System capacity. This capacity information will be

needed in order to determine the amount of coolant

that is required for the Total Cooling System.

Table 4

Many engine failures are related to the cooling

system. The following problems are related to cooling

system failures: Overheating, leakage of the water

pump, and plugged radiators or heat exchangers.

Engine

Refill Capacities

Compartment or System

Engine Only

External System Per OEM

Liters

15 L

(3.3 Imp gal)

These failures can be avoided with correct cooling

system maintenance. Cooling system maintenance is

as important as maintenance of the fuel system and

the lubrication system. Quality of the coolant is as

important as the quality of the fuel and the lubricating

oil.

25.5 L

(5.6 Imp gal)

(1)

(1) The External System includes a radiator or an expansion

tank with the following components: heat exchanger and

piping. Refer to the OEM specifications. Enter the value for the

capacity of the External System in this row.

Coolant is normally composed of three elements:

Water, additives, and glycol.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SEBU8337

39

Maintenance Section

Refill Capacities

Water

• Formation of gel compounds

• Reduction of heat transfer

Water is used in the cooling system in order to

transfer heat.

• Leakage of the water pump seal

Distilled water or deionized water is

recommended for use in engine cooling systems.

• Plugging of radiators, coolers, and small passages

DO NOT use the following types of water in cooling

systems: Hard water, softened water that has been

conditioned with salt, and sea water.

Glycol

Glycol in the coolant helps to provide protection

against the following conditions:

If distilled water or deionized water is not available,

use water with the properties that are listed in Table 5.

• Boiling

Table 5

• Freezing

Acceptable Water

• Cavitation of the water pump

Property

Chloride (Cl)

Sulfate (SO4)

Total Hardness

Total Solids

Acidity

Maximum Limit

40 mg/L

For optimum performance, Perkins recommends a

1:1 mixture of a water/glycol solution.

100 mg/L

170 mg/L

Note: Use a mixture that will provide protection

against the lowest ambient temperature.

340 mg/L

pH of 5.5 to 9.0

Note: 100 percent pure glycol will freeze at a

temperature of −23 °C (−9 °F).

For a water analysis, consult one of the following

sources:

Most conventional antifreezes use ethylene glycol.

Propylene glycol may also be used. In a 1:1 mixture

with water, ethylene and propylene glycol provide

similar protection against freezing and boiling. See

Tables 6 and 7.

• Local water utility company

• Agricultural agent

Table 6

• Independent laboratory

Ethylene Glycol

Additives

Freeze

Protection

Boil

Protection

Concentration

Additives help to protect the metal surfaces of

the cooling system. A lack of coolant additives or

insufficient amounts of additives enable the following

conditions to occur:

50 Percent

60 Percent

−36 °C (−33 °F) 106 °C (223 °F)

−51 °C (−60 °F) 111 °C (232 °F)

NOTICE

• Corrosion

Do not use propylene glycol in concentrations that ex-

ceed 50 percent glycol because of propylene glycol’s

reduced heat transfer capability. Use ethylene glycol

in conditions that require additional protection against

boiling or freezing.

• Formation of mineral deposits

• Rust

• Scale

Table 7

• Foaming of the coolant

Propylene Glycol

Many additives are depleted during engine operation.

These additives must be replaced periodically.

Freeze

Protection

Anti-Boil

Protection

Concentration

50 Percent

−29 °C (−20 °F) 106 °C (223 °F)

Additives must be added at the correct concentration.

Overconcentration of additives can cause the

inhibitors to drop out-of-solution. The deposits can

enable the following problems to occur:

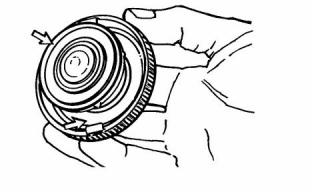

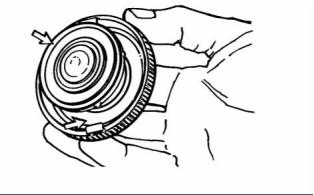

To check the concentration of glycol in the coolant,

measure the specific gravity of the coolant.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

40

SEBU8337

Maintenance Section

Refill Capacities

Coolant Recommendations

Extended Life Coolant (ELC)

The following two coolants are used in Perkins diesel

engines:

Perkins provides Extended Life Coolant (ELC) for

use in the following applications:

Preferred – Perkins Extended Life Coolant (ELC)

• Heavy-duty spark ignited gas engines

• Heavy-duty diesel engines

• Automotive applications

Acceptable – A commercial heavy-duty antifreeze

that meets “ASTM D4985” specifications

NOTICE

The anti-corrosion package for ELC is different from

the anti-corrosion package for other coolants. ELC

is an ethylene glycol base coolant. However, ELC

contains organic corrosion inhibitors and antifoam

agents with low amounts of nitrite. Perkins ELC

has been formulated with the correct amount of

these additives in order to provide superior corrosion

protection for all metals in engine cooling systems.

Do not use a commercial coolant/antifreeze that on-

ly meets the ASTM D3306 specification. This type of

coolant/antifreeze is made for light automotive appli-

cations.

Perkins recommends a 1:1 mixture of water and

glycol. This mixture of water and glycol will provide

optimum heavy-duty performance as a antifreeze.

This ratio may be increased to 1:2 water to glycol if

extra freezing protection is required.

ELC is available in a 1:1 premixed solution . The

Premixed ELC provides freeze protection to −36 °C

(−33 °F). The Premixed ELC is recommended for the

initial fill of the cooling system. The Premixed ELC is

also recommended for topping off the cooling system.

Note: A commercial heavy-duty antifreeze that

meets “ASTM D4985” specifications MAY require a

treatment with an SCA at the initial fill. Read the label

or the instructions that are provided by the OEM of

the product.

ELC Concentrate is also available. ELC Concentrate

can be used to lower the freezing point to −51 °C

(−60 °F) for arctic conditions.

In stationary engine applications and marine engine

applications that do not require anti-boil protection

or freeze protection, a mixture of SCA and water

is acceptable. Perkins recommends a six percent

to eight percent concentration of SCA in those

cooling systems. Distilled water or deionized water

is preferred. Water which has the recommended

properties may be used.

Containers of several sizes are available. Consult

your Perkins dealer or your Perkins distributor for the

part numbers.

ELC Cooling System Maintenance

Correct additions to the Extended Life

Coolant

Engines that are operating in an ambient temperature

above 43 °C (109.4 °F) must use SCA and water.

Engines that operate in an ambient temperature

above 43 °C (109.4 °F) and below 0 °C (32 °F) due

to seasonal variations consult your Perkins dealer

or your Perkins distributor for the correct level of

protection.

NOTICE

Use only Perkins products for pre-mixed or concen-

trated coolants.

Mixing Extended Life Coolant with other products re-

duces the Extended Life Coolant service life. Failure to

follow the recommendations can reduce cooling sys-

tem components life unless appropriate corrective ac-

tion is performed.

Table 8

Coolant Service Life

Coolant Type

Service Life

6,000 Service Hours or

Three Years

Perkins ELC

In order to maintain the correct balance between

the antifreeze and the additives, you must maintain

the recommended concentration of Extended Life

Coolant (ELC). Lowering the proportion of antifreeze

lowers the proportion of additive. This will lower the

ability of the coolant to protect the system from pitting,

from cavitation, from erosion, and from deposits.

Commercial Heavy-Duty

Antifreeze that meets

“ASTM D4985”

3000 Service Hours or

Two Years

Perkins POWERPART

SCA

3000 Service Hours or

Two Years

Commercial SCA and

Water

3000 Service Hours or

Two Years

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

SEBU8337

41

Maintenance Section

Refill Capacities

6. Fill the cooling system with clean water and

operate the engine until the engine is warmed to

49° to 66°C (120° to 150°F).

NOTICE

Do not use a conventional coolant to top-off a cooling

system that is filled with Extended Life Coolant (ELC).

NOTICE

Do not use standard supplemental coolant additive

(SCA).

Incorrect or incomplete flushing of the cooling system

can result in damage to copper and other metal com-

ponents.

When using Perkins ELC, do not use standard SCA’s

or SCA filters.

To avoid damage to the cooling system, make sure to

completely flush the cooling system with clear water.

Continue to flush the system until all the signs of the

cleaning agent are gone.

ELC Cooling System Cleaning

Note: If the cooling system is already using ELC,

cleaning agents are not required to be used at

the specified coolant change interval. Cleaning

agents are only required if the system has been

contaminated by the addition of some other type of

coolant or by cooling system damage.

7. Drain the cooling system into a suitable container

and flush the cooling system with clean water.

Note: The cooling system cleaner must be thoroughly

flushed from the cooling system. Cooling system

cleaner that is left in the system will contaminate the

coolant. The cleaner may also corrode the cooling

system.

Clean water is the only cleaning agent that is required

when ELC is drained from the cooling system.

After the cooling system is drained and after the

cooling system is refilled, operate the engine while

the cooling system filler cap is removed. Operate

the engine until the coolant level reaches the normal

operating temperature and until the coolant level

stabilizes. As needed, add the coolant mixture in

order to fill the system to the specified level.

8. Repeat Steps 6 and 7 until the system is

completely clean.

9. Fill the cooling system with the Perkins Premixed

ELC.

ELC Cooling System Contamination

Changing to Perkins ELC

NOTICE

Mixing ELC with other products reduces the effective-

ness of the ELC and shortens the ELC service life.

Use only Perkins Products for premixed or concen-

trate coolants. Failure to follow these recommenda-

tions can result in shortened cooling system compo-

nent life.

To change from heavy-duty antifreeze to the Perkins

ELC, perform the following steps:

NOTICE

Care must be taken to ensure that all fluids are

contained during performance of inspection, main-

tenance, testing, adjusting and the repair of the

product. Be prepared to collect the fluid with suitable

containers before opening any compartment or dis-

assembling any component containing fluids.

ELC cooling systems can withstand contamination to

a maximum of ten percent of conventional heavy-duty

antifreeze or SCA. If the contamination exceeds ten

percent of the total system capacity, perform ONE of

the following procedures:

Dispose of all fluids according to local regulations and

mandates.

• Drain the cooling system into a suitable container.

Dispose of the coolant according to local

regulations. Flush the system with clean water. Fill

the system with the Perkins ELC.

1. Drain the coolant into a suitable container.

2. Dispos, e of the coolant according to local

regulations.

• Drain a portion of the cooling system into a suitable

container according to local regulations. Then, fill

the cooling system with premixed ELC. This should

lower the contamination to less than 10 percent.

3. Flush the system with clean water in order to

remove any debris.

4. Use Perkins cleaner to clean the system. Follow

the instruction on the label.

• Maintain the system as a conventional Heavy-Duty

Coolant. Treat the system with an SCA. Change

the coolant at the interval that is recommended for

the conventional Heavy-Duty Coolant.

5. Drain the cleaner into a suitable container. Flush

the cooling system with clean water.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

42

SEBU8337

Maintenance Section

Refill Capacities

Commercial Heavy-Duty Antifreeze and

SCA

Table 11 is an example for using the equation that

is in Table 10.

Table 11

NOTICE

Example Of The Equation For Adding The SCA To

The Heavy-Duty Coolant At The Initial Fill

Commercial Heavy-Duty Coolant which contains

Amine as part of the corrision protection system must

not be used.

Total Volume

of the Cooling

System (V)

Multiplication

Factor

Amount of SCA

that is Required

(X)

NOTICE

Never operate an engine without water temperature

regulators in the cooling system. Water temperature

regulators help to maintain the engine coolant at the

correct operating temperature. Cooling system prob-

lems can develop without water temperature regula-

tors.

15 L (4 US gal)

× 0.045

0.7 L (24 oz)

Adding The SCA to The Heavy-Duty

Coolant For Maintenance

Heavy-duty antifreeze of all types REQUIRE periodic

additions of an SCA.

Check the antifreeze (glycol concentration) in

order to ensure adequate protection against boiling

or freezing. Perkins recommends the use of a

refractometer for checking the glycol concentration.

Test the antifreeze periodically for the concentration

of SCA. For the interval, refer to the Operation

and Maintenance Manual, “Maintenance Interval

Schedule” (Maintenance Section). Test the

concentration of SCA.

Perkins engine cooling systems should be tested

at 500 hour intervals for the concentration of

Supplemental Coolant Additive (SCA).

Additions of SCA are based on the results of the

test. The size of the cooling system determines the

amount of SCA that is needed.

Additions of SCA are based on the results of the test.

An SCA that is liquid may be needed at 500 hour

intervals.

Use the equation that is in Table 12 to determine the

amount of Perkins SCA that is required, if necessary:

Refer to Table 9 for part numbers and for quantities

of SCA.

Table 12

Equation For Adding The SCA To The Heavy-Duty

Coolant For Maintenance

Table 9

Perkins Liquid SCA

V × 0.014 = X

Part Number

Quantity

V is the total volume of the cooling system.

X is the amount of SCA that is required.

21825755

.

Adding the SCA to Heavy-Duty Coolant

at the Initial Fill

Table 13 is an example for using the equation that

is in Table 12.

Commercial heavy-duty antifreeze that meets “ASTM

D4985” specifications MAY require an addition of

SCA at the initial fill. Read the label or the instructions

that are provided by the OEM of the product.

Table 13

Example Of The Equation For Adding The SCA To

The Heavy-Duty Coolant For Maintenance

Total Volume

of the Cooling

System (V)

Multiplication

Factor

Amount of SCA

that is Required

(X)

Use the equation that is in Table 10 to determine the

amount of Perkins SCA that is required when the

cooling system is initially filled.

15 L (4 US gal)

× 0.014

0.2 L (7 oz)

Table 10

Equation For Adding The SCA To The Heavy-Duty

Coolant At The Initial Fill

V × 0.045 = X

V is the total volume of the cooling system.

X is the amount of SCA that is required.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

SEBU8337

43

Maintenance Section

Refill Capacities

Cleaning the System of Heavy-Duty

Antifreeze

NOTICE

These recommendations are subject to change with-

out notice. Contact your local Perkins distributor for

the most up to date recommendations.

Perkins cooling system cleaners are designed

to clean the cooling system of harmful scale

and corrosion. Perkins cooling system cleaners

dissolve mineral scale, corrosion products, light oil

contamination and sludge.

Diesel Fuel Requirements

• Clean the cooling system after used coolant is

drained or before the cooling system is filled with

new coolant.

Satisfactory engine performance is dependent on

the use of a good quality fuel. The use of a good

quality fuel will give the following results: long engine

life and acceptable exhaust emissions levels. The

fuel must meet the minimum requirements that are

stated in table 14.

• Clean the cooling system whenever the coolant is

contaminated or whenever the coolant is foaming.

NOTICE

i03040204

Fluid Recommendations

(Fuel Specification)

The footnotes are a key part of the Perkins Specifica-

tion for Distillate Diesel Fuel Table. Read ALL of the

footnotes.

• Glossary

• ISO International Standards Organization

• ASTM American Society for Testing and Materials

• HFRR High Frequency Reciprocating Rig for

Lubricity testing of diesel fuels

• FAME Fatty Acid Methyl Esters

• CFR Co-ordinating Fuel Research

• LSD Low Sulfur Diesel

• ULSD Ultra Low Sulfur Diesel

• RME Rape Methyl Ester

• SME Soy Methyl Ester

• EPA Environmental Protection Agency of the

United States

General Information

NOTICE

Every attempt is made to provide accurate, up to date

information. By use of this document you agree that

Perkins Engines Company Limited is not responsible

for errors or omissions.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]()

![]()

![]()

44

SEBU8337

Maintenance Section

Refill Capacities

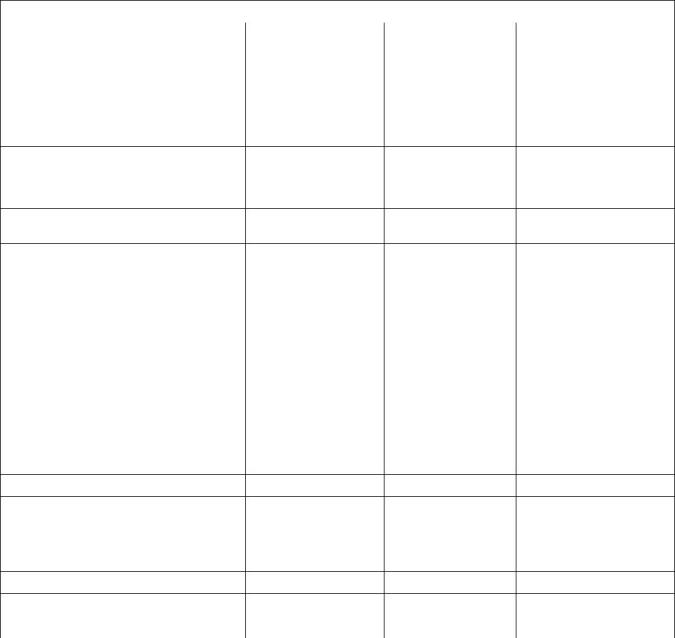

Table 14

Perkins Specification for Distillate Diesel Fuel

(1)

Property

Aromatics

Ash

UNITS

Requirements

35% maximum

0.01% maximum

0.35% maximum

“ASTM”Test

D1319

“ISO”Test

“ISO”3837

“ISO”6245

“ISO”4262

%Volume

%Weight

%Weight

D482

Carbon Residue on

10% Bottoms

D524

Cetane Number

Cloud Point

(2)

-

40 minimum

D613/D6890

D2500

“ISO”5165

“ISO”3015

°C

The cloud point must

not exceed the lowest

expected ambient

temperature.

-

Copper Strip

Corrosion

No. 3 maximum

D130

“ISO”2160

Density at 15 °C

(59 °F)

Kg / M

°C

3

801 minimum and 876

maximum

No equivalent test

D86

“ISO 3675 ”“ISO 12185”

“ISO”3405

(3)

Distillation

10% at 282 °C

(539.6 °F) maximum

90% at 360 °C (680 °F)

maximum

Flash Point

°C

-

legal limit

D93

“ISO”2719

Thermal Stability

Minimum of 80%

reflectance after aging

for 180 minutes at

150 °C (302 °F)

D6468

No equivalent test

Pour Point

°C

6 °C (42.8 °F) minimum

below ambient

D97

“ISO”3016

temperature

Sulfur

(1)(4)

%mass

1% maximum

D5453/D26222

D445

“ISO 20846 ”“ISO 20884”

“ISO”3405

Kinematic Viscosity

(5)

“MM”

2

“/S (cSt)”

The viscosity of the

fuel that is delivered to

the fuel injection pump.

“1.4 minimum/4.5

maximum”

Water and sediment

Water

% weight

% weight

% weight

0.1% maximum

0.1% maximum

0.05% maximum

D1796

D1744

D473

“ISO”3734

No equivalent test

“ISO”3735

Sediment

(continued)

This document has been printed from SPI². Not for Resale

![]()

SEBU8337

45

Maintenance Section

Refill Capacities

(Table 14, contd)

Gums and Resins

(6)

mg/100mL

mm

10 mg per 100 mL

maximum

D381

“ISO”6246

Lubricity corrected

0.52 maximum

D6079

“ISO”12156-1

wear scar diameter at

60 °C (140 °F).

(7)

(1) This specification includes the requirements for Ultra Low Sulfur Diesel (ULSD). ULSD fuel will have ≤ 15 ppm (0.0015%) sulfur. Refer to

“ASTM D5453”, “ASTM D2622”, or “ISO 20846, ISO 20884” test methods. This specification includes the requirements for Low Sulfur

Diesel (LSD). LSD fuel will have ≤500 ppm (0.05%) sulfur. Refer to following:“ASTM 5453, ASTM D2622”, “ISO 20846”, and “ISO 20884

test methods”.

(2) A fuel with a higher cetane number is recommended in order to operate at a higher altitude or in cold weather.

(3) “Via standards tables, the equivalent API gravity for the minimum density of 801 kg / m

3

(kilograms per cubic meter) is 45 and for the

maximum density of 876 kg / m is 30”.

3

(4) Regional regulations, national regulations or international regulations can require a fuel with a specific sulfur limit. Consult all applicable

regulations before selecting a fuel for a given engine application. Perkins fuel systems and engine components can operate on high sulfur

fuels. Fuel sulfur levels affect exhaust emissions. High sulfur fuels also increase the potential for corrosion of internal components.

Fuel sulfur levels above 0.5% may significantly shorten the oil change interval. For additional information, refer to this manual, “Fluid

recommendations (General lubricant Information)”.

(5) The values of the fuel viscosity are the values as the fuel is delivered to the fuel injection pumps. Fuel should also meet the minimum

viscosity requirement and the fuel should meet the maximum viscosity requirements at 40 °C (104 °F) of either the “ASTM D445” test

method or the “ISO 3104” test method. If a fuel with a low viscosity is used, cooling of the fuel may be required to maintain 1.4 cSt or

greater viscosity at the fuel injection pump. Fuels with a high viscosity might require fuel heaters in order to lower the viscosity to 4.5

cSt at the fuel injection pump.

(6) Follow the test conditions and procedures for gasoline (motor).

(7) The lubricity of a fuel is a concern with low sulfur and ultra low sulfur fuel. To determine the lubricity of the fuel, use the “ISO 12156-1

or ASTM D6079 High Frequency Reciprocating Rig (HFRR)” test. If the lubricity of a fuel does not meet the minimum requirements,

consult your fuel supplier. Do not treat the fuel without consulting the fuel supplier. Some additives are not compatible. These additives

can cause problems in the fuel system.

Fuel with a low cetane number can be the root cause

of problems during cold start.

NOTICE

Operating with fuels that do not meet the Perkins rec-

ommendations can cause the following effects: Start-

ing difficulty, poor combustion, deposits in the fuel in-

jectors, reduced service life of the fuel system, de-

posits in the combustion chamber, and reduced ser-

vice life of the engine.

Viscosity

Viscosity is the property of a liquid of offering

resistance to shear or flow. Viscosity decreases with

increasing temperature. This decrease in viscosity

follows a logarithmic relationship for normal fossil

fuel. The common reference is to kinematic viscosity.

This is the quotient of the dynamic viscosity that is

divided by the density. The determination of kinematic

viscosity is normally by readings from gravity flow

viscometers at standard temperatures. Refer to “ISO

3104” for the test method.

Diesel Fuel Characteristics

Perkins Recommendation

Cetane Number

The viscosity of the fuel is significant because fuel

serves as a lubricant for the fuel system components.

Fuel must have sufficient viscosity in order to lubricate

the fuel system in both extremely cold temperatures

and extremely hot temperatures. If the kinematic

viscosity of the fuel is lower than 1.4 cSt at the fuel

injection pump damage to the fuel injection pump

can occur. This damage can be excessive scuffing

and seizure. Low viscosity may lead to difficult hot

restarting, stalling and loss of performance. High

viscosity may result in seizure of the pump.

Fuel that has a high cetane number will give a shorter

ignition delay. This will produce a better ignition

quality. Cetane numbers are derived for fuels against

proportions of cetane and heptamethylnonane in the

standard CFR engine. Refer to “ISO 5165” for the

test method.

Cetane numbers in excess of 45 are normally

expected from current diesel fuel. However, a cetane

number of 40 may be experienced in some territories.

The United States of America is one of the territories

that can have a low cetane value. A minimum cetane

value of 40 is required during average starting

conditions. A higher cetane value may be required

for operations at high altitudes or in cold weather

operations.

Perkins recommends kinematic viscosities of 1.4 and

4.5 mm2/sec that is delivered to the fuel injection

pump.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

46

SEBU8337

Maintenance Section

Refill Capacities

Density

Lubricity

Density is the mass of the fuel per unit volume

at a specific temperature. This parameter has a

direct influence on engine performance and a direct

influence on emissions. This determines the heat

output from a given injected volume of fuel. This

is generally quoted in the following kg/m at 15 °C

(59 °F).

This is the capability of the fuel to prevent pump

wear. The fluid’s lubricity describes the ability of the

fluid to reduce the friction between surfaces that are

under load. This ability reduces the damage that is

caused by friction. Fuel injection systems rely on the

lubricating properties of the fuel. Until fuel sulfur limits

were mandated, the fuel’s lubricity was generally

believed to be a function of fuel viscosity.

Perkins recommends a value of density of 841 kg/m

in order to obtain the correct power output. Lighter

fuels are acceptable but these fuels will not produce

the rated power.

The lubricity has particular significance to the current

low viscosity fuel, low sulfur fuel and low aromatic

fossil fuel. These fuels are made in order to meet

stringent exhaust emissions. A test method for

measuring the lubricity of diesel fuels has been

developed and the test is based on the HFRR

method that is operated at 60 °C (140 °F). Refer to

“ISO 12156 part 1 and CEC document F06-A-96” for

the test method.

Sulfur

The level of sulfur is governed by emissions

legislations. Regional regulation, national regulations

or international regulations can require a fuel with

a specific sulfur limit. The sulfur content of the fuel

and the fuel quality must comply with all existing local

regulations for emissions.

Lubricity wear scar diameter of 0.52 mm (0.0205 inch)

MUST NOT be exceeded. The fuel lubricity test must

be performed on a HFRR, operated at 60 °C (140 °F).

Refer to “ISO 12156-1 ”.

By using the test methods “ASTM D5453, ASTM

D2622, or ISO 20846 ISO 20884”, the content of

sulfur in low sulfur diesel (LSD) fuel must be below

500 PPM 0.05%. By using the test methods “ASTM

D5453, ASTM D2622, or ISO 20846 ISO 20884”, the

content of sulfur in ultra low sulfur (ULSD) fuel must

be below 15 PPM 0.0015%. The use of LSD fuel and

the use of ULSD fuel are acceptable provided that the

fuels meet the minimum requirements that are stated

in table 14. The lubricity of these fuels must not

exceed wear scar diameter of 0.52 mm (0.0205 inch).

The fuel lubricity test must be performed on a HFRR,

operated at 60 °C (140 °F). Refer to “ISO 12156-1 ”.

Fuel additives can enhance the lubricity of a fuel.

Contact your fuel supplier for those circumstances

when fuel additives are required. Your fuel supplier

can make recommendations for additives to use

and for the proper level of treatment. For more

information, refer to “Fuel Additive”.

Distillation

This is an indication of the mixture of different

hydrocarbons in the fuel. A high ratio of light weight

hydrocarbons can affect the characteristics of

combustion.

In some parts of the world and for some applications,

high sulfur fuels above 0.5% by mass might only

be available. Fuel with very high sulfur content

can cause engine wear. High sulfur fuel will have

a negative impact on emissions of particulates.

High sulfur fuel can be used provided that the local

emissions legislation will allow the use. High sulfur

fuel can be used in countries that do not regulate

emissions.

Classification of the Fuels

Diesel engines have the ability to burn a wide variety

of fuels. These fuels are divided into four general

groups: Ref to table 15

When only high sulfur fuels are available, it will

be necessary that high alkaline lubricating oil is

used in the engine or that the lubricating oil change

interval is reduced. Refer to this Operation and

Maintenance Manual, “Fliud Recommendations

(Genernal Lubrication Information)” for information

on sulfur in fuel.

This document has been printed from SPI². Not for Resale

![]()

SEBU8337

47

Maintenance Section

Refill Capacities

Table 15

• “MIL-DTL-5624U NATO F44 (JP-5)”

Fuel Groups

Group 1

Classification

• “MIL-DTL-38219D (USAF) F44 JP-7”

• “NATO F63”

Preferred fuels

Full life of the

Product

Group 2

Group 3

Group 4

Permissible

fuels with an

appropriate fuel

additive

These fuels

MAY cause

reduced

engine life and

performance

• “NATO XF63”

• “ASTM D1655 JET A”

• “ASTM D1655 JET A1”

Permissible

fuels with an

appropriate fuel

additive

These fuels

WILL cause

reduced

engine life and

performance

Note: These fuels are only acceptable provided that

these fuels are used with an appropriate fuel additive.

These fuels must meet the requirements that are

stated in table 14. Fuel samples should be analyzed

for the compliance. These fuels MUST NOT exceed

lubricity wear scar diameter of 0.52 mm (0.0205 inch).

The fuel lubricity test must be performed on a

HFRR, operated at 60 °C (140 °F). Refer to “ISO

12156-1 ”. Fuels must have minimum viscosity of

1.4 centistokes that is delivered to the fuel injection

pump. Fuel cooling may be required in order to

maintain minimum viscosity of 1.4 centistokes that is

delivered to the fuel injection pump.

Biodiesel

Group 1 Specifications (Preferred Fuels)

This group of fuel specifications is considered

acceptable:

• EN590 DERV Grade A, B, C, E, F, Class, 0, 1, 2,

3, and 4

Group 3 Specifications (Permissible

Fuels)

• “BS2869 Class A2” Off-Highway Gas Oil Red

Diesel

• “ASTM D975”, Class 1D , and Class 2D

This group of fuel specification must be used only

with the appropriate fuel additive. This fuel WILL

reduce engine life and performance.

• “JIS K2204 Grades 1,2,3 and Special Grade 3”

This grade of fuel must meet the minimum lubricity

requirements that are stated in table 14.

“JIS 2203#1 and #2 Toyu”

Note: The use of LSD fuel and the use of ULSD

fuel is acceptable provided that the fuels meet the

minimum requirements that are stated in table 14.

The lubricity of these fuels must not exceed wear

scar diameter of 0.52 mm (0.0205 inch). The lubricity

test must be performed on a HFRR, operated at

60 °C (140 °F). Refer to “ISO 12156-1 ”. By using the

test methods “ASTM D5453, ASTM D2622, or ISO

20846 ISO 20884”, the content of sulfur in LSD fuel

must be below 500 PPM 0.05%. By using the test

methods “ASTM D5453, ASTM D2622, or ISO 20846

ISO 20884”, the content of sulfur in ULSD fuel must

be below 15 PPM 0.0015%.

Note: These fuels are only acceptable provided that

these fuels are used with an appropriate fuel additive.

These fuels must meet the requirements that are

stated in table 14. Fuel samples should be analyzed

for the compliance. These fuels MUST NOT exceed

lubricity wear scar diameter of 0.52 mm (0.0205 inch).

The fuel lubricity test must be performed on a

HFRR, operated at 60 °C (140 °F). Refer to “ISO

12156-1 ”. Fuels must have minimum viscosity of

1.4 centistokes that is delivered to the fuel injection

pump. Fuel cooling may be required in order to

maintain minimum viscosity of 1.4 centistokes that is

delivered to the fuel injection pump.

Group 2 Specifications (Permissible

Fuels)

Group 4 Biodiesel

Biodiesel is a fuel that can be defined as mono-alkyl

esters of fatty acids. Biodiesel is a fuel that can

be made from a variety of feedstock. The most

commonly available biodiesel in europe is Rape

Methyl Ester (REM). This biodiesel is derived from

rapeseed oil. Soy Methyl Ester (SME) is the most

common biodiesel in the United States. This biodiesel

is derived from soybean oil. Soybean oil or rapeseed

oil are the primary feedstocks. These fuels are

together known as Fatty Acid Methyl Esters (FAME).

This group of fuel specifications is considered

acceptable, but only with an appropriate fuel additive,

but these fuels MAY reduce the engine life and

performance.

• “MIL-DTL-83133E NATO F34 (JP-8)”

• “MIL-DTL-83133E NATO F35 ”

This document has been printed from SPI². Not for Resale

![]()

48

SEBU8337

Maintenance Section

Refill Capacities

Raw pressed vegetable oils are NOT acceptable for

use as a fuel in any concentration in compression

engines. Without esterification, these oils gel in the

crankcase and the fuel tank. These fuels may not be

compatible with many of the elastomers that are used

in engines that are manufactured today. In original

forms, these oils are not suitable for use as a fuel

in compression engines. Alternate base stocks for

biodiesel may include animal tallow, waste cooking

oils, or a variety of other feedstocks. In order to use

any of the products that are listed as fuel, the oil

must be esterified.

• Biodiesel may pose low ambient temperature

problems for both storage and operation. At low

ambient temperatures, fuel may need to be stored

in a heated building or a heated storage tank. The

fuel system may require heated fuel lines, filters,

and tanks. Filters may plug and fuel in the tank may

solidify at low ambient temperatures if precautions

are not taken. Consult your biodiesel supplier for

assistance in the blending and attainment of the

proper cloud point for the fuel.

• Biodiesel has poor oxidation stability, which

can result in long term problems in the storage

of biodiesel. The poor oxidation stability may

accelerate fuel oxidation in the fuel system.

This is especially true in engines with electronic

fuel systems because these engines operate at

higher temperatures. Consult the fuel supplier for

oxidation stability additives.

Note: Engines that are manufactured by Perkins

are certified by use of the prescribed Environmental

Protection Agency (EPA) and European Certification

fuels. Perkins does not certify engines on any other

fuel. The user of the engine has the responsibility

of using the correct fuel that is recommended by

the manufacturer and allowed by the EPA and other

appropriate regulatory agencies.

• Biodiesel is a fuel that can be made from a variety

of feedstock. The feedstock that is used can

affect the performance of the product. Two of the

characteristics of the fuel that are affected are

cold flow and oxidation stability. Contact your fuel

supplier for guidance.

Recommendation for the use of biodiesel

The neat biodiesel must conform to “EN14214” or

“ASTM D6751” regulations. A maximum of 30%

mixture of biodiesel can be used in mineral diesel fuel.

The mineral diesel fuel must conform to “EN590”,

“ASTM D975” or “BS2869 Grade A2” regulations.

• Biodiesel or biodiesel blends are not recommended

for engines that will operate occasionally. This

is due to poor oxidation stability. If the user is

prepared to accept some risk, then limit biodiesel

to a maximum of B5. Examples of applications that

should limit the use of biodiesel are the following:

Standby Generator sets and certain emergency

vehicles

Note: When biodiesel, or any blend of biodiesel is

used, the user has the responsibility for obtaining the

proper local exemptions, regional exemptions, and/or

national exemptions that are required for the use

of biodiesel in any Perkins engine that is regulated

by emissions standards. Biodiesel that meets EN

14214 is acceptable. The biodiesel must be blended

with an acceptable distillate diesel fuel at the

• Biodiesel is an excellent medium for microbial

contamination and growth. Microbial contamination

and growth can cause corrosion in the fuel system

and premature plugging of the fuel filter. The

use of conventionalanti-microbial additives and

the effectiveness of conventional anti-microbial

additives in biodiesel is not known. Consult your

supplier of fuel and additive for assistance.

maximum stated percentages. However, the following

operational recommendations must be followed:

• The oil change interval can be affected by the use

of biodiesel. Use Services Oil Analysis in order

to monitor the condition of the engine oil. Use

Services Oil Analysis also in order to determine the

oil change interval that is optimum.

• Care must be taken in order to remove water

from fuel tanks. Water accelerates microbial

contamination and growth. When biodiesel is

compared to distillate fuels, water is naturally more

likely to exist in the biodiesel.

• Confirm that biodiesel is acceptable for use with

the manufacturer of the fuel filters.

• In a comparison of distillate fuels to biodiesel,

biodiesel provides less energy per gallon by 5% to

7%. Do NOT change the engine rating in order to

compensate for the power loss. This will help avoid

engine problems when the engine is converted

back to 100 percent distillate diesel fuel.

Fuel for Cold Weather Operation

The European standard “EN590” contains climate

dependant requirements and a range of options. The

options can be applied differently in each country.

There are 5 classes that are given to arctic climates

and severe winter climates. 0, 1, 2, 3, and 4.

• The compatibility of the elastomers with biodiesel

is being monitored. The condition of seals and

hoses should be monitored regularly.

This document has been printed from SPI². Not for Resale

![]()

SEBU8337

49

Maintenance Section

Refill Capacities

Fuel that complies with “EN590 ” CLASS 4 can be

used at temperatures as low as −44 °C (−47.2 °F).

Refer to “EN590” for a detailed discretion of the

physical properties of the fuel.

Perkins recognizes the fact that additives may

be required in some special circumstances. Fuel

additives need to be used with caution. Contact

your fuel supplier for those circumstances when

fuel additives are required. Your fuel supplier can

recommend the appropriate fuel additive and the

correct level of treatment.

The diesel fuel “ASTM D975 1-D” that is used in the

united states of america may be used in very cold

temperatures that are below −18 °C (−0.4 °F).

Note: For the best results, your fuel supplier should

treat the fuel when additives are required. The treated

fuel must meet the requirements that are stated in

table 14.

In extreme cold ambient conditions, you may also

use fuels that are listed in the table 16. These fuels

are intended to be used in temperatures that can be

as low as −54 °C (−65.2 °F).

Table 16

i03040140

Fluid Recommendations

Light Distillate Fuels

Grade

(1)

Specification

“MIL-DTL-5624U”

“MIL-DTL-83133E”

“ASTM D1655”

JP-5

General Lubricant Information

JP-8

Jet-A-1

Because of government regulations regarding the

certification of exhaust emissions from the engine,

the lubricant recommendations must be followed.

(1) The use of these fuels is acceptable with an appropriate fuel

additive and the fuels must meet minimum requirements that

are stated in Table 14. Fuel samples should be analyzed for

the compliance. Fuels MUST NOT exceed 0.52 mm lubricity

wear scar diameter that is tested on a HFFR . The test must be

performed at 60 °C. Refer to “ISO 12156-1”. Fuels must have

minimum viscosity of 1.4 centistokes that is delivered to the

fuel injection pump. Fuel cooling may be required in order to

maintain minimum viscosity of 1.4 centistokes that is delivered

to the fuel injection pump.

• EMA____________Engine Manufacturers Association

• API_____________________American Petroleum Institute

• SAE___________________________________________Society Of

Automotive Engineers Inc.

Engine Manufacturers Association (EMA)

Oils

Mixing alcohol or gasoline with diesel fuel can pro-

duce an explosive mixture in the engine crankcase

or the fuel tank. Alcohol or gasoline must not be

used in order to dilute diesel fuel. Failure to follow

this instruction may result in death or personal in-

jury.

The “Engine Manufacturers Association

Recommended Guideline on Diesel Engine Oil” is

recognized by Perkins. For detailed information

about this guideline, see the latest edition of EMA

publication, “EMA DHD -1”.

There are many other diesel fuel specifications that

are published by governments and by technological

societies. Usually, those specifications do not review

all the requirements that are addressed in table 14.

To ensure optimum engine performance, a complete

fuel analysis should be obtained before engine

operation. The fuel analysis should include all of the

properties that are stated in the table 14.

API Oils

The Engine Oil Licensing and Certification System by

the American Petroleum Institute (API) is recognized

by Perkins. For detailed information about this

system, see the latest edition of the “API publication

No. 1509”. Engine oils that bear the API symbol are

authorized by API.

Fuel Additive

Supplemental diesel fuel additives are not generally

recommended. This is due to potential damage to

the fuel system or the engine. Your fuel supplier

or the fuel manufacturer will add the appropriate

supplemental diesel fuel additives.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

50

SEBU8337

Maintenance Section

Refill Capacities

In order to make the correct choice of a commercial

oil, refer to the following explanations:

EMA DHD-1 – The Engine Manufacturers

Association (EMA) has developed lubricant

recommendations as an alternative to the API oil

classification system. DHD-1 is a Recommended

Guideline that defines a level of oil performance for

these types of diesel engines: high speed, four stroke

cycle, heavy-duty, and light duty. DHD-1 oils may

be used in Perkins engines when the following oils

are recommended: API CH-4, API CG-4, and API

CF-4. DHD-1 oils are intended to provide superior

performance in comparison to API CG-4 and API

CF-4.

g00546535

Illustration 18

Typical API symbol

DHD-1 oils will meet the needs of high performance

Perkins diesel engines that are operating in many

applications. The tests and the test limits that are

used to define DHD-1 are similar to the new API

CH-4 classification. Therefore, these oils will also

meet the requirements for diesel engines that require

low emissions. DHD-1 oils are designed to control the

harmful effects of soot with improved wear resistance

and improved resistance to plugging of the oil filter.

These oils will also provide superior control of piston

deposit for engines with either two-piece steel pistons

or aluminum pistons.

Diesel engine oils CC, CD, CD-2, and CE have

not been API authorized classifications since 1

January 1996. Table 17 summarizes the status of

the classifications.

Table 17

API Classifications

Current

CH-4, , CI-4

-

Obsolete

CE, CC, CD

CD-2 (1)

All DHD-1 oils must complete a full test program

with the base stock and with the viscosity grade of

the finished commercial oil. The use of “API Base

Oil Interchange Guidelines” are not appropriate for

DHD-1 oils. This feature reduces the variation in

performance that can occur when base stocks are

changed in commercial oil formulations.

(1) The oil CD-2 is for a two-cycle diesel engine. Perkins does not

sell engines that utilize CD-2 oil.

Terminology