產(chǎn)品中心

美國(guó)強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國(guó)麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國(guó)珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢圖冊(cè)

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國(guó)道依茨 韓國(guó)大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

珀金斯2306A(C)-E14發(fā)動(dòng)機(jī)故障維修診斷

詳細(xì)描述

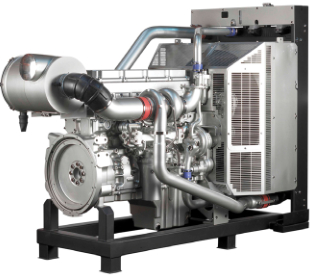

Perkins 2300 Series

Models 2306A-E14 and 2306C-E14

DIAGNOSTIC MANUAL

6 cylinder turbocharged diesel engine

Publication TSD 3457E, Issue 2.

© Proprietary information of Perkins Engines Company Limited, all rights reserved.

The information is correct at the time of print.

Published in December 2006 by Technical Publications,

Perkins Engines Company Limited, Peterborough PE1 5NA England.

Diagnostic Manual, TSD 3457E, Issue 2

i

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

Intermittent low power or power cut-outs

Test 6

Note: Use this procedure only if the engine DOES NOT shut down completely (the engine did not have to be

restarted).

Probable root causes

Speed setting input signal

Faulty electrical connections

Fuel supply

Note: If the problem only occurs under certain conditions (high engine speed, full load or engine operating

temperature, etc) then perform the test under those operating conditions.

Perform the following tests

1 Check the ECM connectors J1/P1 and J2/P2, customer connector, engine speed/timing sensor connectors

and the unit injector connectors and associated wiring for damage, abrasion, corrosion or incorrect attachment.

Refer to Test 39: Inspecting electrical connectors on page 82 for additional information.

2 Check the electronic service tool for a logged 168-02 Intermittent Battery Power to the ECM diagnostic code.

Check the battery connection at the customer connector and the ECM connector. Refer to the electrical

schematic. Perform a pull test on the customer connector. Perform a pull test on pins 48, 52, 53, 61, 63, 65

and 70. The wires should remain in the connectors during the pull test. Refer to Test 39: Inspecting electrical

connectors on page 82.

3 If the problem occurs only after the engine is warmed up and disappears after the engine has been allowed

to cool, the circuit breakers may be exceeding the trip point because of overheating. Check the circuit breakers

on the engine, reset if required.

Note: Aftermarket engine protection devices may interrupt power to the ECM. Check for correct installation

and operation of aftermarket engine protection devices. Aftermarket devices may need to be bypassed to

continue testing.

4 If a PWM speed control is fitted, connect an electronic service tool to the service tool connector. Turn the

key switch to the ON position, engine OFF. Check that a 91-08 Invalid Throttle Signal diagnostic code has not

been recently logged. Monitor the PWM input. The duty cycle should be between 5 and 10 percent at low load

and increase with load. If the throttle position change is erratic or out of range the problem is with the external

speed control.

5 Connect an electronic service tool and check that a 190-02 Loss of Engine Speed Signal diagnostic code is

not active. The code should not be active. If the 190-02 code is active check to see if a 342-02 Loss of Backup

Engine Speed Sensor diagnostic code has been recently logged. If the electronic service tool indicates that a

342-02 code has been recently logged perform a pull test on the wires to the backup engine speed/timing

sensor. Refer to Test 39: Inspecting electrical connectors on page 82. If a 342-02 code has not been recently

logged and the 190-02 code is active refer to Test 46: Engine speed/timing circuit test on page 126.

6 Check for a fuel supply problem and check fuel pressure. Refer to Test 29: Engine has a fuel supply problem

on page 65.

42

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Electronic service tool will not communicate with the ECM

Test 7

Probable root causes

ECM software or ECM

Electronic service tool or communication adapter cable problem

Perkins Data Link

Electrical power supply to the ECM connector or wiring problem in electronic system wiring harness

Perform the following tests

Note: If the engine starts but will not communicate proceed with this test. If the engine will not start, refer to

Test 2: Engine cranks but will not start on page 38. If the engine will not crank, refer to Test 1: Engine will not

crank on page 37. Aftermarket engine protection devices may interrupt power to the ECM and prevent

communications with the electronic service tool. Check for correct installation and operation of aftermarket

protection devices, they may need to be bypassed to continue.

1 In the event that the ECM on the engine is new, the engine will not start or communicate until the ECM is

programmed. Refer to "Programming an ECM using flash programming" on page 27.

2 Check the ECM connectors J1/P1 and J2/P2, customer connector, service tool connectors and associated

wiring for damage, abrasion, corrosion or incorrect attachment. Refer to Test 39: Inspecting electrical

connectors on page 82 for additional information.

3 Check that the key switch is in the ON position and any override switches are not creating the problem. Start

the engine and then connect the electronic service tool. If communication occurs when the engine is started,

but not when the key switch is in the ON position, some type of system override is interrupting power to the

ECM. Repair as required.

4 Check that battery voltage is present at pin-A and Pin-B of the service tool connector (the communication

adapter power LED will be off if it is not receiving power).

5 Check the electronic service tool connections and wiring. Connect another electronic service tool and cable

to the system to check that the fault is with the electronic service tool.

6 Disconnect the ECM P1 connector. Install a bypass harness, connect the bypass harness directly to the

electronic service tool cable and retest. Refer to Test 45: Perkins Data Link circuit test on page 118. If the ECM

communicates with the bypass installed, either the machine wiring or another device is causing the data link

communication problem. Repair as required.

Diagnostic Manual, TSD 3457E, Issue 2

43

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

ECM will not accept factory passwords

Test 8

Probable root causes

Error entering password

Incorrect serial number (engine, ECM, or electronic service tool), total tattletale, or reason code used to

obtain password

Perform the following tests

1 Check that the correct passwords were entered. Check each character in the password for accuracy (for

instance letter I vs. number 1, Z vs. 2, O vs. 0, etc). Turn the key switch to the OFF position for 30 seconds

and then retry.

2 Check that the electronic service tool is on the "Factory Passwords" screen. Check the engine serial number

used to calculate the password is correct. Check the total tattletale, reason code, electronic service tool serial

number and ECM serial number is correct. Refer to "Factory passwords" on page 23 for more details.

44

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Excessive black smoke

Test 9

Probable root causes

Air inlet restriction or air system leaks

Engine speed/timing signal: injection timing or calibration, incorrect engine speed/timing wheel orientation

assembly, engine speed/timing sensor calibration error after replacement

Faulty inlet air manifold pressure sensor, atmospheric pressure sensor, or sensor calibration

ECM/software problem

Fuel supply: low supply pressure, air in low pressure fuel system, poor fuel quality

Incorrect valve adjustment

Perform the following tests

1 Connect an electronic service tool and compare atmospheric and inlet pressure readings. Check for filter

restriction derates and alarms. Check air inlet and exhaust systems for restrictions and leaks. Check for a failed

turbocharger. Refer to the relevant procedure in the Workshop Manual. Replace plugged air filters, or clean

filters, as described in the User’s Handbook, and repair any leaks found. Check for correct operation of the

inlet air manifold pressure and atmospheric pressure sensors. Refer to Test 41: Analogue sensor open or

short circuit test on page 91.

2 Check calibration of the engine speed/timing sensor, recalibrate if required. Refer to Test 47: Engine speed/

timing calibration on page 134. Check for correct orientation between crankshaft and camshaft drive gears,

repair as required. Refer to the relevant procedure in the Workshop Manual.

3 Monitor atmospheric pressure with an electronic service tool. Observe inlet air manifold pressure, fuel

position, rated fuel position and smoke fuel limit while the engine is operating under full load.

Fuel position = rated fuel position

and

smoke fuel limit > rated fuel limit

Note: A problem with the smoke fuel limit will only create black smoke problems on acceleration, not steady

state operation. Check for a restriction in the atmosphere path, remove dirt and debris if required. Atmospheric

2

pressure should range from 50 to 100 kPa (7.5 to 15 lb/in ) depending on your area of operation. Refer to Test

41: Analogue sensor open or short circuit test on page 91.

4 Check for a fuel supply problem and check the fuel pressure. Refer to Test 29: Engine has a fuel supply

problem on page 65.

5 Check valve adjustment.

Diagnostic Manual, TSD 3457E, Issue 2

45

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Excessive white smoke

Test 10

Note: Some white smoke may be present during cold start-up conditions when the engine is operating

normally.

Probable root cause

Faulty coolant temperature sensor

Engine speed/timing signal: injection timing or calibration, incorrect engine speed/timing wheel orientation

assembly, engine speed/timing sensor calibration error after replacement

ECM software

Fuel supply

Combustion system problem

Perform the following tests

1 Check for a fuel supply problem and check the fuel pressure. Refer to Test 29: Engine has a fuel supply

problem on page 65.

2 Ensure that the correct type of fuel is used and check that there is no water or other contaminants in the fuel.

3 Check that cold mode is active when the engine is cold. Monitor coolant temperature status on an electronic

service tool. Observe coolant temperature and ensure the reading is reasonable. If temperature reading is

incorrect, refer to Test 41: Analogue sensor open or short circuit test on page 91.

4 Check timing calibration of the engine speed/timing sensor, recalibrate if required. Refer to Test 47: Engine

speed/timing calibration on page 134. Check for correct orientation between crankshaft and camshaft drive

gears, repair as required.

5 Connect an electronic service tool and check that the correct software is installed for the engine

configuration and application. Refer to Chapter 3, Programming parameters.

6 Excessive valve, piston, ring and/or liner wear, or low cranking speed can result in reduced compression

pressure, resulting in white smoke. Coolant leakage into the cylinder or exhaust system can also produce

symptoms similar to white smoke emissions from unburned fuel. Refer to the Workshop Manual.

46

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Excessive blue smoke

Test 11

Note: Blue smoke is produced by the engine when there is excessive oil in the cylinder bores.

Probable root cause

Too much engine oil in the sump

Air inlet or exhaust restriction

Loose, worn or damaged turbocharger

Combustion system problem

Perform the following tests

1 Check that the engine oil level is correct. If necessary, drain the engine oil until the correct level is obtained.

2 Check the crankcase breather for blockages or restrictions.

3 Check the air filter restriction indicator. Ensure that the filter element of the air cleaner is clean and

serviceable.

4 Check the air inlet and exhaust systems for blockages, restrictions or damage to pipes and hoses.

5 Check that the turbocharger mountings are not loose.

6 Check the turbine housing of the turbocharger for excessive dirt or carbon.

7 Check for worn turbocharger bearings.

8 Check the turbine blades for damage and ensure that the turbine rotates freely.

9 Check the compressor housing for indications of oil.

10 Check that the valve clearances are correct and adjust if necessary.

11 Refer to the Workshop Manual; low compression can be caused by:

Broken, worn or sticking piston rings

Worn cylinder bores

Worn valves, valve stem seals or valve guides

Valves not fully closed

Cylinder head gasket faulty

Cracked cylinder head

Diagnostic Manual, TSD 3457E, Issue 2

47

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Engine cannot reach correct rev/min

Test 12

Note: If this problem occurs only under load, refer to Test 4: Low power/poor or no response to throttle on

page 40.

Probable root causes

Engine is in cold mode or derated

ECM software

External speed control input

Faulty intake manifold pressure sensor, atmosphere signal or calibration

Fuel supply

Air inlet or exhaust restriction or air system leaks

Air supply/low boost

Perform the following tests

1 Connect an electronic service tool and check that the engine has exited cold mode. Check for active engine

derates. Check that the programming parameters are correct. Refer to Chapter 3, Programming parameters.

Note: The engine may be derated due to altitude or other factors.

2 Monitor the external speed control (if fitted) on an electronic service tool. Observe the position and check

that it can reach 100 percent.

Note: If PWM or analogue speed controls are selected, i.e. digital speed control not installed, but the selected

PWM or analogue control is not connected, the engine will run at 1100 rpm.

3 Check for a fuel supply problem and check the fuel pressure. Refer to Test 29: Engine has a fuel supply

problem on page 65.

4 Check air inlet and exhaust systems for restrictions and leaks. Look for a diagnostic lamp indication, or

tripped restriction indicators (if fitted) associated with plugged air filters. Replace plugged air filters, or clean

filters, as described in the User’s Handbook, and repair any leaks found. Also refer to Test 41: Analogue

sensor open or short circuit test on page 91.

48

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Poor acceleration or response

Test 13

Probable root causes

The engine is in cold mode or a derate mode.

ECM software

External speed control input

Incorrect intake manifold pressure sensor or atmosphere signal

Air inlet or exhaust restriction or leaks

Fuel supply

Perform the following tests

1 Connect an electronic service tool. Check that the engine has exited cold mode operation. The engine will

not respond as fast until it has warmed to operating temperature.

2 Check that the correct ECM software is installed. Refer to Chapter 3, Programming parameters.

3 Monitor the external speed control input on an electronic service tool. Observe position and check that the

reading is stable and can reach 100 percent.

4 Inspect ECM connectors J1/P1 and J2/P2, engine interface connectors, and the unit injector connectors for

correct connection. Repair or replace as required. Refer to Test 39: Inspecting electrical connectors on page

82. Perform the cylinder cut-out test to check for any non-operable unit injectors, and replace only those

diagnosed as faulty by the cylinder cut-out check. Connect an electronic service tool and cut-out each cylinder

to isolate the misfiring cylinder(s). If results are inconclusive, perform the test under load or shut off half of the

engine's cylinders and repeat cut-out on the remaining active cylinders to locate those misfiring. If it can be

isolated to a specific cylinder(s), refer to Test 48: Injector solenoids circuit test on page 138.

5 Monitor atmospheric pressure with an electronic service tool. Observe intake manifold pressure while the

2

engine is operating under full load. Atmospheric pressure should range from 50 to 100 kPa (7.5 to 15 lb/in ).

6 Check air inlet and exhaust systems for restrictions and leaks. Look for a warning lamp or diagnostic lamp

indication, or tripped restriction indicators (if fitted) associated with plugged air filters. Replace plugged air

filters, or clean filters, as described in the User’s Handbook, and repair any leaks found.

7 Check for a fuel supply problem and check the fuel pressure. Refer to Test 29: Engine has a fuel supply

problem on page 65.

Diagnostic Manual, TSD 3457E, Issue 2

49

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Poor fuel consumption

Test 14

Note: This is NOT an electronic system problem. Refer to the Workshop Manual for additional information on

the following tests.

Probable root causes

Incorrect engine operation

Engine speed/timing signal: injection timing or calibration, incorrect engine speed/timing wheel orientation,

engine speed/timing sensor calibration error after replacement

Faulty electronic unit injector(s) (individual cylinder malfunction)

Fuel supply

Air inlet or exhaust restrictions or air system leaks

Perform the following tests

1 Check timing calibration of engine speed/timing sensor and recalibrate if required. Refer to Test 47: Engine

speed/timing calibration on page 134. Check for correct orientation between crankshaft and camshaft drive

gears, repair as required. Refer to the Workshop Manual.

2 Inspect ECM connector J2/P2 and the unit injector connector for correct connection. Refer to Test 39:

Inspecting electrical connectors on page 82. Connect an electronic service tool and cut out each cylinder to

isolate the misfiring cylinder(s). If results are inconclusive, shut off half of the engine's cylinders and repeat cut-

out on remaining active cylinders to locate those that are misfiring. Refer to Test 48: Injector solenoids circuit

test on page 138.

3 Check for a fuel supply problem and check the fuel pressure. Refer to Test 29: Engine has a fuel supply

problem on page 65.

4 Check air inlet and exhaust systems for restrictions and leaks. Look for a warning lamp or diagnostic lamp

indication, or tripped restriction indicators (fitted) associated with plugged air filters. Replace plugged air filters,

or clean filters, as described in the User’s Handbook, and repair any leaks found.

50

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Too much vibration

Test 15

Note: This is NOT an electronic system problem. Refer to the Workshop Manual for additional information on

the following tests.

Possible root causes

Loose or faulty vibration damper

Engine supports are loose, wrong or are incorrectly torqued

Equipment may not be in alignment or is out of balance

Engine misfiring or running rough

Perform the following tests

1 Check vibration damper for damage. Tighten bolts. If vibration damper bolt holes have damage or wear,

replace with new parts. Install a new vibration damper if necessary.

2 Run the engine through its speed range while looking for loose or broken mounts or brackets. Tighten all

mounting bolts. Install new components if necessary.

3 Check alignment and balance, correct if required.

4 Refer to Test 3: Engine misfires, runs rough or is unstable on page 39.

Diagnostic Manual, TSD 3457E, Issue 2

51

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Noise coming from cylinder

Test 16

Note: This is NOT an electronic system problem. Refer to the Workshop Manual for additional information on

the following tests.

Probable root causes

Low quality fuel

Incorrect fuel injection timing calibration

Faulty electronic unit injector(s)

Incorrect valve train operation or valve train noise (clicking)

Damage to valve spring(s) or locks

Not enough lubrication

Loud tapping sound from rocker cover

Damage to valve(s)

Unit injector plunger

Damaged camshaft lobe

Little or no valve clearance, worn valve seat or face of valve

Perform the following tests

1 Check for a fuel supply problem and check the fuel pressure. Refer to Test 29: Engine has a fuel supply

problem on page 65.

2 Check and calibrate electronic injection timing with an electronic service tool. Refer to Test 47: Engine

speed/timing calibration on page 134.

3 Connect an electronic service tool and cut-out each cylinder to isolate the misfiring cylinder(s). If results are

inconclusive, perform test under load or shut off half of the engine's cylinders and repeat cut-out on remaining

active cylinders to locate those misfiring. Refer to Test 48: Injector solenoids circuit test on page 138.

4 Damage to valve spring(s). Replace damaged parts. Damage to camshaft. Replace damaged parts. Clean

engine valve train thoroughly. Replace damaged valve lifters. Inspect camshaft lobes for damage. Look for

valves that do not move freely. Adjust using the procedure in the Workshop Manual. Refer to Test 18: Valve

rotocoil or spring lock is free on page 54.

5 Install new parts where necessary.

Caution: Broken locks can cause the valve to fall into the cylinder.This will cause severe damage.

6 Check lubrication in valve compartment. There must be a strong flow of oil at high engine idle rev/min, but

only a small flow of oil at low rev/min. Oil passages must be clean, especially those that send oil to the cylinder

head.

7 Refer to Test 17: Excessive valve clearance on page 53. Adjust using the procedure in the Workshop

Manual.

8 Replace the valve(s) and adjust using the procedure in the Workshop Manual.

9 Plunger may be stuck, repair as required with reference to the Workshop Manual.

10 Refer to the Workshop Manual.

11 Reconditioning of cylinder head is required.

52

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Excessive valve clearance

Test 17

Note: This is NOT an electronic system problem. Refer to the Workshop Manual for additional information on

the following tests.

Probable root causes

Not enough lubrication

Rocker arm worn at face that contacts bridge

Bridges for valves worn/incorrect adjustment

End of valve stem worn

Worn cams on camshaft

Loose or broken rocker shaft retaining bolt

Perform the following tests

1 Check lubrication in valve compartment. There must be a strong flow of oil at high engine idle rev/min, but

only a small flow at low rev/min. Oil passages must be clean.

2 If there is too much wear, install new parts or rocker arms. Adjust valve clearance using the procedure in

the Workshop Manual.

3 Adjust or replace bridges as necessary. If there is too much wear, install new parts. Adjust valve clearance

using the procedure in the Workshop Manual.

4 If there is too much wear, adjust valve clearance using the procedure in the Workshop Manual.

5 Clean engine valve train thoroughly. Check camshaft for wear. Check for free movement of valves or bent

valve stem. Adjust using the procedure in the Workshop Manual.

6 Check valve clearance. Check for free movement of valves or bent valve stems. Install a new camshaft.

Adjust using the procedure in the Workshop Manual.

7 Repair or replace rocker shaft retaining bolt as required.

Diagnostic Manual, TSD 3457E, Issue 2

53

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Valve rotocoil or spring lock is free

Test 18

Note: This is NOT an electronic system problem. Refer to the Workshop Manual for additional information on

the following tests.

Probable root causes

Cracked inlet valve Rotocoil

Broken spring locks

Broken valve spring(s)

Broken valve

Perform the following tests

1 Determine cause of engine overspeed that would crack the Rotocoil.

2 Install new parts where necessary.

Caution: Broken locks can cause the valve to fall into the cylinder, and will cause severe damage.

3 Install new valve spring(s).

4 Replace valve and other damaged parts.

54

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Mechanical noise (knock) in engine

Test 19

Note: This is NOT an electronic system problem. Refer to the Workshop Manual for additional information on

the following tests.

Probable root causes

Faulty accessory or driven equipment

Damaged camshaft lobe

Damaged gears

Failure of bearing for connecting rod or damaged crankshaft

Perform the following tests

1 Attempt to isolate the source of the noise. If suspected, remove and inspect engine accessories. Repair or

renew as necessary. Refer to the Workshop Manual.

2 If noise may be coming out of the cylinder head, check for damage to camshaft or valve train components.

Replace damaged parts. Clean the engine valve train thoroughly. Check for valves that do not move freely.

Adjust using the procedure in the Workshop Manual. Refer to Test 16: Noise coming from cylinder on page 52.

3 Install new parts where necessary.

4 Inspect the connecting rod bearings and the bearing surfaces (journals) on the crankshaft. Install new parts

where necessary.

Diagnostic Manual, TSD 3457E, Issue 2

55

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Oil in cooling system

Test 20

Note: This is NOT an electronic system problem. Refer to the Workshop Manual for additional information on

the following tests.

Probable root causes

Faulty engine oil cooler core or driven equipment oil cooler (if fitted)

Failure of cylinder head gasket or coolant seals

Perform the following tests

1 Inspect each cooler and replace or repair faulty oil cooler.

2 Check cylinder liner projection. Install a new cylinder head gasket and new coolant seals in the spacer plate.

Tighten the cylinder head bolts according to the procedure in the Workshop Manual.

56

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Fuel in cooling system

Test 21

Note: This is NOT an electronic system problem. Refer to the Workshop Manual for additional information on

the following tests.

Probable root causes

Internal cylinder head problem

Perform the following tests

1 Remove the valve cover. Remove the fuel supply and fuel return line from cylinder head. Cap the fuel return

2

connector and apply 700 kPa (100 lb/in ) maximum air pressure to the fuel supply connector. Check for fuel

leakage around the unit injector. If leakage is present, it will be necessary to remove the unit injector and install

a new O-Ring seal.

Diagnostic Manual, TSD 3457E, Issue 2

57

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Coolant in lubricating oil

Test 22

Note: This is NOT an electronic system problem. Refer to the Workshop Manual for additional information on

the following tests.

Probable root causes

Failure of any of the oil cooler cores

Failure of cylinder head gasket or coolant seals

Crack in cylinder head

Cracked or broken cylinder liner

Crack in cylinder block

Perform the following tests

1 Install a new oil cooler core. Drain crankcase and refill with clean lubricant. Install new oil filters.

2 Check cylinder liner projection. Install a new cylinder head gasket and new liner coolant seals in the spacer

plate. Tighten the cylinder head bolts according to the procedure in the Workshop Manual.

3 Check for cracks in cylinder head. Repair or replace as required.

4 Check for cracked liners. Replace cracked cylinder liners.

5 Repair or replace cylinder block.

58

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Fuel dilution of lubricating oil

Test 23

Note: This is NOT an electronic system problem. Refer to the Workshop Manual for additional information on

the following tests.

Probable root causes

Leaking fuel seals on unit injector case or barrel

Leaking fuel seals on cylinder head adapters

Unit injector nozzle tip leakage or breakage

Cracked fuel supply manifold

Fuel transfer pump seal leaking with plugged weep hole

Perform the following tests

1 Inspect for signs of damage to unit injector fuel seals, replace if required.

2 Inspect for signs of damage to cylinder head fuel seals, replace if required.

3 Inspect for signs of unit injector damage, replace as required.

4 Inspect for signs of fuel supply manifold damage, replace if required.

5 Repair or replace fuel lift pump.

Diagnostic Manual, TSD 3457E, Issue 2

59

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Engine has early wear

Test 24

Note: This is NOT an electronic system problem. Refer to the Workshop Manual for additional information on

the following tests.

Probable root causes

Dirt in lubricating oil

Air inlet leaks

Fuel leakage into lubricating oil

Low oil pressure

Perform the following tests

1 Remove dirty lubricating oil. Install new filters. Put clean oil in the engine. Check oil filter bypass valve for a

weak or broken spring.

2 Inspect all gaskets and connections. Repair if leaks are found.

3 Fuel leakage into lubricating oil will cause high fuel consumption and low engine oil pressure. This condition

may also increase the oil level in the crankcase. Refer to Test 23: Fuel dilution of lubricating oil on page 59.

4 Refer to Test 25: Engine has low oil pressure on page 61.

60

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Engine has low oil pressure

Test 25

Note: This is NOT an electronic system problem. Refer to the Workshop Manual for additional information on

the following tests.

Caution: Do not operate engine with low oil pressure, engine damage will result. If measured oil pressure is

low, discontinue engine operation until the problem is corrected.

Probable root causes

Low Engine Oil Pressure Warning (event code) 360-01

Oil pressure data is below normal operating range for two seconds. The fault and event will be active, and

logged only if the engine has been running for at least 15 seconds. The warning lamp is also illuminated.

Low Engine Oil Pressure Action Alert (event code) 360-02

Oil pressure data is below normal operating range for two seconds. The fault and event will be logged.

Low Engine Oil Pressure Shutdown (event code) 360-03

Engine oil pressure has reached a level where the engine is shutdown unless critical override is active.

Oil level may be too low

Dirty oil filters or restriction in oil cooler(s)

Diesel fuel in lubricating oil

Oil pressure relief valve does not close

Oil pump suction pipe problem, faulty oil pump or scavenge oil pump

Too much clearance between rocker arm shaft and rocker arms

Too much clearance between camshaft and camshaft bearings

Too much clearance between crankshaft and crankshaft bearings

Perform the following tests

1 Add oil if required.

2 Check the operation of the bypass valve for the filter. Install new oil filters i, f required. Clean or install new

oil cooler core(s). Remove dirty oil from the engine. Put clean oil in the engine.

3 Check for presence of fuel in lubricating oil. Refer to Test 23: Fuel dilution of lubricating oil on page 59.

4 Clean the bypass valve and housing. Install new parts as necessary.

5 Check the oil pump inlet screen for obstructions. Check for air leakage into the supply to the oil pump.

Examine oil pump for excessive wear. Repair or replace as needed.

6 Install new camshaft and camshaft bearings if necessary.

7 Inspect the main bearings and replace as necessary.

Diagnostic Manual, TSD 3457E, Issue 2

61

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Engine uses too much lubricating oil

Test 26

Note: This is NOT an electronic system problem. Refer to the Workshop Manual for additional information on

the following tests.

Probable root causes

Oil leaks

Too much lubricating oil in engine

Oil temperature is too high

Too much oil in the valve compartment

Turbocharger seal ring failure

Worn valve guides

Worn piston rings

Perform the following tests

1 Find all oil leaks. Repair as required. Check for dirty crankcase breather(s).

2 Remove extra oil. Find where extra fluid comes from. Repair as required. Put correct amount of oil in engine.

3 Check for restrictions in the oil cooler or an oil cooler bypass valve stuck in the open position.

4 Check for high coolant temperature. Refer to Test 27: Engine coolant is too hot on page 63.

5 Check that the dowel is installed in the left bolt hole of the rocker shaft. This dowel is located between the

rocker shaft and valve cover base. Check shaft and valve cover base. Check for dirty breather element.

6 Check inlet manifold for oil and repair the turbocharger if necessary.

7 Reconditioning of the cylinder head is required.

8 Inspect and install new parts as required.

62

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Engine coolant is too hot

Test 27

Note: This is NOT an electronic system problem. Refer to the Workshop Manual for additional information on

the following tests.

Probable root causes

High Coolant Temperature Warning (event code) 361-01

The engine is running, the coolant temperature sensor reading is greater than or equal to the preset

temperature for two seconds. Diagnostic codes 262-03 +5V Supply Above Normal or 262-04 +5V Supply

Below Normal are not active.

High Coolant Temperature Action Alert (event code) 361-02

The coolant temperature sensor reading is greater than or equal to the preset temperature for two seconds.

Diagnostic code 262-03 +5V Supply Above Normal is not active. The fault and event will be logged.

High Coolant Temperature Shutdown (event code) 360-03

Engine coolant temperature has reached a level where the engine is shutdown unless Critical Override is

active.

Radiator damage or obstruction

Low coolant level in system

Combustion gases in coolant

Incorrect fuel injection timing calibration

Faulty coolant thermostats

Faulty coolant pump

Too much load on the system

Perform the following tests

1 Clean obstructions from the radiator; check that there are no restrictions to the air flow.

2 Check that the fan belts are not slipping.

3 Add coolant to cooling system. Check for leaks.

4 Inspect coolant for presence of bubbles.

5 Check coolant thermostats for correct operation. Inspect coolant pump impeller vanes for damage or

erosion. Repair as necessary.

6 Reduce the load.

Diagnostic Manual, TSD 3457E, Issue 2

63

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Oil at the exhaust

Test 28

Note: This is NOT an electronic system problem. Refer to the Workshop Manual for additional information on

the following tests.

Probable root causes

Turbocharger seal ring failure

Too much oil in the valve compartment

Worn valve guides

Worn piston rings

Perform the following tests

1 Check inlet manifold for oil and repair the turbocharger if necessary.

2 Check that the dowel is installed in the left bolt hole of the rocker shaft.

3 Reconditioning of the cylinder head is required.

4 Inspect and install new parts as required.

64

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Engine has a fuel supply problem

Test 29

Note: This is NOT an electronic system problem. Refer to the Workshop Manual for additional information on

the following tests.

Probable root causes

Low fuel level

Poor fuel quality

Unit injector priming problem

Low supply pressure

Fuel supply circuit

Incorrect fuel type

Water in fuel

Perform the following tests

1 Visually check fuel level (do not rely on fuel gauge only). Check the fuel pressure.

2 In temperatures below 0 °C (32 °F) check for congealed fuel (wax). Check fuel tank for foreign objects which

may block the fuel supply.

3 Check for fuel line restrictions and repair or replace as required. Refer to the Workshop Manual.

4 Monitor exhaust for smoke while cranking. If smoke is not present there may be a fuel supply problem.

5 Check for air in the low pressure fuel supply system. Purge air from the low pressure fuel supply circuit with

the hand priming pump and cranking the engine in 30 second cycles, pausing at least 2 minutes between

cranking cycles to allow the starter motor to cool. Loosen low pressure fuel line fitting on inlet to pressure

regulating valve and hand prime again if air in fuel continues. Also, use of a sight glass in the low pressure

supply line can be helpful in diagnosing air in the fuel.

6 Check fuel pressure after the filter in the supply circuit during cranking. Refer to the Workshop Manual for

correct pressure values. If pressure is low, check for plugged fuel filters. If pressure is still low, repair or replace

fuel lift pump, fuel lift pump coupling, and fuel pressure regulating valve as needed.

7 Check for air in the low pressure fuel supply system after replacing filters, working on the low pressure fuel

supply circuit or replacing unit injectors. Check fuel pressure after the filter in the supply circuit during cranking.

Refer to the Workshop Manual for correct pressure values. If pressure is low, check for plugged fuel filters. If

pressure is still low, repair or replace fuel lift pump, fuel lift pump coupling, and fuel pressure regulating valve

as needed.

Diagnostic Manual, TSD 3457E, Issue 2

65

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Indicator lamp not functioning correctly

Probable root causes

Test 30

Notes:

For details regarding wiring harness refer to the engine electrical schematic. This wiring is the responsibility

of the OEM.

Faulty bulb

Engine wiring

Battery voltage

Perform the following tests

1 Turn key switch OFF and check ECM connector J1/P1 and associated wiring for damage, abrasion,

corrosion or incorrect attachment. Refer to Test 39: Inspecting electrical connectors on page 82.

2 Measure the voltage between (+Battery) and (-Battery) at ECM connector J1/P1. The voltage should be

between 22.0 and 27.0 Volts DC for a 24 Volt system. If the voltage is out of range refer to Test 40: Electrical

power supply to the ECM on page 88.

3 Connect a jumper wire between the suspect lamp driver of ECM connector J1/P1 and (-Battery) for J1/28 to

J1/31 or (+Battery) for J1/10, J1/19 and J1/20. If the lamp illuminates the circuit is functioning normally but the

ECM is not completing the lamp circuit. Refer to Test 40: Electrical power supply to the ECM on page 88.

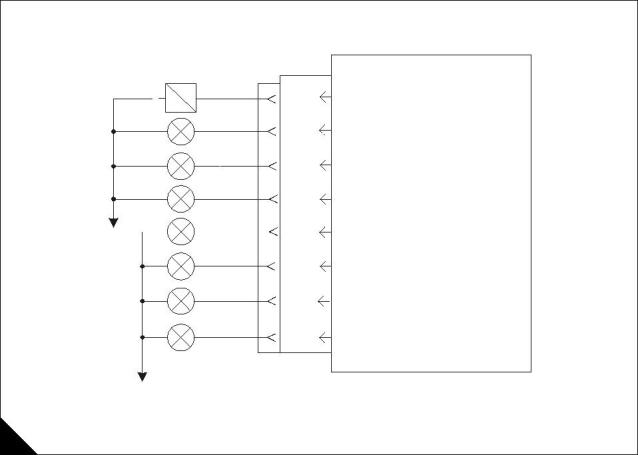

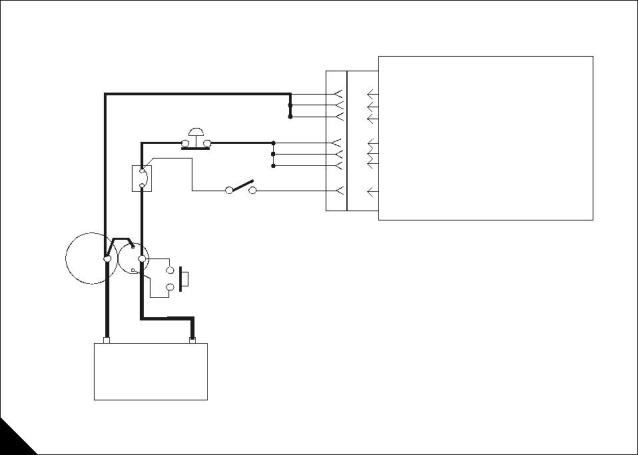

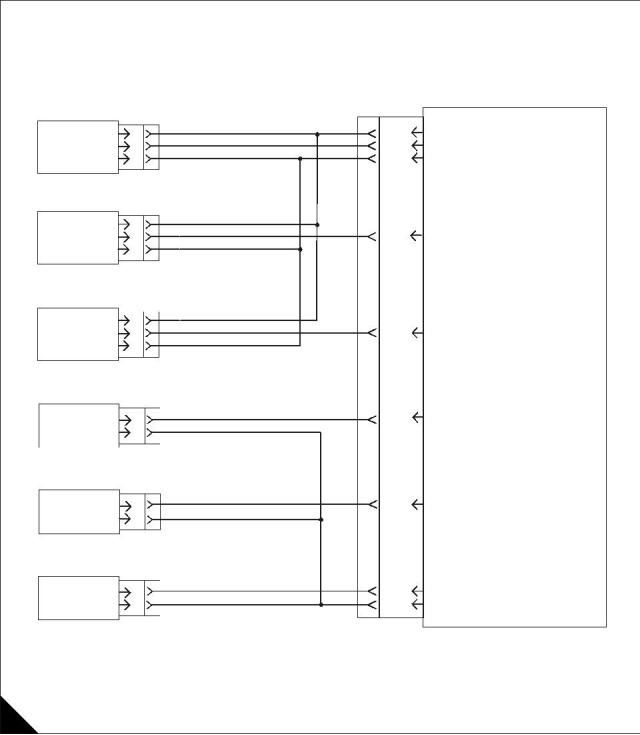

Indicator lamp schematic

Outputs may be used to drive lamps or relays. Refer to the wiring diagrams for full connection details.

Note: If very low current lamps or LED’s are connected to these outputs, a diagnostic code may be generated

even if the lamps or LED’s are functioning correctly.

ECM

Crank

Terminate

J1/13

J1/10

Crank Terminate Output

Shutdown Lamp Output

Shutdown

Action Alert

Warning

Action Alert Lamp Output

Warning Lamp Output

J1/19

J1/20

J1/31

J1/28

J1/29

System Fault

Oil Pressure

Coolant Temp

Diagnostic Lamp Output

Oil Pressure Lamp Output

Coolant Temperature Lamp Output

Overspeed Lamp Output

B-

Overspeed

J1/30

P1 J1

B+

A

HA0008

66

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Inlet air manifold temperature is too high

Test 31

Note: This is NOT an electronic system problem. Refer to the Workshop Manual for additional information on

the following tests.

Probable root causes

High Inlet Air Temperature Warning (event code) 368-01

The engine is running, the inlet air manifold temperature sensor reading is greater than the preset level for two

seconds. Diagnostic codes 262-03 +5 V Supply Above Normal or 262-04 +5 V Supply Below Normal are not

active. The event code and diagnostic code will be logged.

High Inlet Air Temperature Action Alert (event code) 368-02

The engine is running, the inlet air manifold temperature sensor reading is greater than or equal to the preset

level for at least two seconds. Diagnostic codes 262-03 +5 V Supply Above Normal or 262-04 +5 V Supply

Below Normal are not active. The event code and diagnostic code will be logged.

Incorrect fuel injection timing calibration

Low air inlet system pressure

Air inlet system has a restriction

Perform the following tests

1 Connect an electronic service tool and check for engine speed/timing error. Test 47: Engine speed/timing

calibration on page 134.

2 Check pressure in the air inlet manifold. Check for air inlet leaks. Look for restrictions at the air cleaner.

Check for leaks between inlet manifold and turbocharger. Repair or renew as necessary.

3 Check for air inlet restrictions. Refer to the Workshop Manual. Repair as necessary.

Diagnostic Manual, TSD 3457E, Issue 2

67

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Engine has a high fuel temperature

Test 32

Note: This is NOT an electronic system problem. Refer to the Workshop Manual for additional information on

the following tests.

Probable root causes

High Fuel Temp Warning (event code) 363-01

The engine speed is greater than 1000 rev/min, the fuel temperature sensor reading is greater than 60 °C

(140 °F) for 30 seconds. Diagnostic codes 262-03 +5V Supply Above Normal or 262-04 +5V Supply Below

Normal are not active. The event code and diagnostic code will be logged and the warning lamp is illuminated.

Incorrect sensor installation

Low fuel level

Poor fuel quality

Low supply pressure

Insufficient size of fuel tank

A fuel cooler may be required

Perform the following tests

1 Check that the fuel temperature sensor has been correctly installed. Refer to the Workshop Manual.

2 Refer to Test 29: Engine has a fuel supply problem on page 65.

68

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Diagnostic procedures with an event code

General information

This section is to be used for diagnosing problems that have event codes but do not have ACTIVE diagnostic

codes.

Event codes

Event codes indicate an actual engine fault, e.g. low oil pressure, rather than an electronic component failure.

There are three possible levels of severity of the fault.

Level 1 - Operator Warning

To warn the operator or machine control system of a possible condition that requires operator attention.

Level 2 - Action (Derate or Alert)

To inform the operator or machine control system to take action to enable the correct control of the system. In

most cases the OEM will use this level for a controlled shutdown of the engine in order to protect it from

damage.

Note: There are no derates set on the 2806/2306 engines. The TIPSS/EST Service Tool incorrectly shows

Action Alerts as Derates on certain screens.

Level 3 - Shutdown

At this level the ECM will immediately stop the engine unless critical override is enabled and signal that a

critical fault level has been reached.

Caution: If critical override is enabled the product is now operating in a condition outside its scope of supply

and may cause injury or be damaged in such a way as to invalidate the warranty.

Diagnostic Manual, TSD 3457E, Issue 2

69

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

4

2300 Series

Diagnostic tests

High intake manifold pressure

Test 33

Event

Code

E162-1

E162-2

High intake manifold pressure Warning

High intake manifold pressure Action Alert

Probable root causes

Engine overload

Perform the following tests

1 Intake manifold pressure sensor circuit

Check the intake manifold pressure reading with TIPSS-EST and ensure it is reasonable. The pressure should

decrease as load decreases. If the reading is not correct, diagnose the sensor circuit.

70

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Low oil pressure

Test 34

Event

Code

E360-1

E360-2

E360-3

Low oil pressure Warning

Low oil pressure Action Alert

Low oil pressure Shutdown

Probable root causes

Low oil level

High oil temperature/low viscosity

Blocked oil filter

Oil pressure sensor circuit

Blocked oil cooler

Faulty oil pump/oil pump bypass valve

Perform the following tests

1 Low oil level

Check oil level and add oil as necessary.

2 High oil temperature/low viscosity

If present, diagnose the oil cooler circuit. High oil temperature causes oil viscosity to be low which can cause

low oil pressure.

3 Blocked oil filter

Replace oil filters if there is any doubt as to their condition

4 Oil pressure sensor circuit

Diagnose the sensor circuit.

5 Blocked oil cooler

An oil cooler restriction can cause low oil pressure and high oil temperature.

Diagnostic Manual, TSD 3457E, Issue 2

71

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

High coolant temperature

Test 35

Event

Code

High coolant temperature Warning

High coolant temperature Action Alert

High coolant temperature Shutdown

E361-1

E361-2

E361-3

Probable root causes

High ambient temperature

Low coolant level/cooling system leaks

Insufficient air or coolant flow through heat exchanger or radiator

Faulty coolant thermostats

Coolant temperature sensor circuit

Insufficient coolant flow

High inlet air temperature

Exhaust restriction

Combustion gasses in coolant

Perform the following tests

1 High ambient temperature

Determine if ambient air temperature is within design specifications for the cooling system.

2 Low coolant level/cooling system leaks

Check coolant level. Low coolant level can be the effect of overheating rather than the cause. Run the engine

to operating temperature and determine if leaks occur before the engine overheats.

3 Insufficient air or coolant flow through heat exchanger or radiator

Check radiator cooling fins for obstructions. Check radiator cooling fan (if fitted) operation. Check for sufficient

flow and temperature of coolant through the heat exchanger (if fitted).

4 Faulty coolant temperature control

Check thermostats.

5 Coolant temperature sensor circuit

Check the coolant temperature reading on TIPSS-EST and ensure it is reasonable. The coolant temperature

reading should rise steadily as the engine is warmed. If the reading is not correct, diagnose the sensor circuit.

6 Insufficient coolant flow

Check the coolant pumps for correct operation. Check the coolant thermostats for correct operation.

7 High inlet air temperature

Check air temperature into the engine.

8 Exhaust restriction

Check exhaust system back pressure.

72

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Engine overspeed

Test 36

Event

Code

E362-1

E362-2

E362-3

Engine overspeed Warning

Engine overspeed Action Alert

Engine overspeed Shutdown

Probable root causes

Engine overspeed set point

Incorrect speed setting

Driven equipment motoring

Slow governor response

Perform the following tests

1 Engine overspeed set point

Check that the engine overspeed set point is correctly programmed. Only the Warning level can be changed

using the electronic service tool, The Action Alert and Shutdown levels are factory set and cannot be changed.

2 Check analogue, PWM or remote manual throttle settings.

3 Driven equipment motoring

Determine if the driven equipment has additional energy inputs that could drive the engine beyond it’s rated

rev/min.

4 Slow governor response

Watch the engine response to worst case step loading and step unloading on the TIPSS-EST graphing screen.

Refer to "Governor gain parameters" on page 33 if the engine speed undershoot or engine speed overshoot

is excessive.

Diagnostic Manual, TSD 3457E, Issue 2

73

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

High fuel temperature

Test 37

Event

Code

E363-1

E363-2

High fuel temperature Warning

High fuel temperature Action Alert

Probable root causes

Fuel temperature sensor circuit

Inadequate size of fuel tank or low fuel level in tank

Perform the following tests

1 Fuel temperature sensor circuit

Check the temperature reading on TIPSS-EST and ensure it is reasonable. If the reading is not correct,

diagnose the sensor circuit.

2 Fuel is used to cool the injectors and surplus fuel is passed back to the fuel tank

If the fuel tank capacity is inadequate this return fuel will heat up the tank until the fuel temperature is

unacceptable. If necessary fit a fuel cooler.

74

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

High intake manifold air temperature

Test 38

Event

Code

E368-1

E368-2

High inlet air temperature Warning

High inlet air temperature Action Alert

Probable root causes

Air temperature sensor circuit

Insufficient coolant flow through charge cooler

High ambient temperature

Perform the following tests

1 Air temperature sensor circuit

Check the air temperature reading on TIPSS-EST and ensure it is reasonable and rises steadily as the engine

is warmed. If the reading is not correct, diagnose the sensor circuit.

2 Insufficient coolant flow through charge cooler

Check the coolant inlet temperature and compare to regulated temperature. If OK, check air cooler coolant

outlet temperature. A high temperature difference between outlet and inlet temperature indicates insufficient

flow rate.

3 If ambient temperature exceeds 50 °C (122 °F) engine power must be derated.

Diagnostic Manual, TSD 3457E, Issue 2

75

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Diagnostic procedures with a diagnostic fault code

General information

Some of the wiring detailed in this section may be supplied by the OEM and may differ from the diagrams in

this manual.

Refer to the OEM supplied wiring diagrams where appropriate.

Diagnostic codes

Diagnostic codes alert the operator that a problem exists and indicate the nature of the problem to the service

technician. Diagnostic codes may be viewed using an electronic service tool (TIPSS-EST).

Diagnostic codes consist of three parts, MID, CID and FMI

The MID or Module IDentifier indicates which electronic module generated the diagnostic code. The ECM

is MID=24.

The CID, or Component IDentifier, indicates which component in the system the diagnostic code is for.

The FMI, or Failure Mode Identifier indicates what the failure mode is. Refer to "Diagnostic terminology" on

page 78 for additional details.

Note: Do not confuse diagnostic codes with diagnostic events. Events can be logged in the ECM to track

information about the engine. An example would be a low oil pressure event. An event is generated when the

engine oil pressure is low but not out of range for the sensor. This does not indicate a problem with the sensor,

rather it indicates a problem with the engine oil pressure. Refer to "Diagnostic procedures with an event code"

on page 69 for more information.

Active diagnostic codes

An active diagnostic code represents a problem with the electronic control system that should be investigated

and corrected as soon as possible.

When an active diagnostic code is generated, the diagnostic warning indicator is activated to alert the operator.

If the condition generating the diagnostic occurs only for a brief moment, the message will disappear and the

diagnostic code will be Logged in the ECM memory.

Logged diagnostic codes

When the ECM generates a diagnostic code, it usually logs the code in permanent memory within the ECM.

The ECM has an internal diagnostic clock and will record the hour of the first occurrence, the hour of the last

occurrence and the number of occurrences of the code.

Knowing when and how often the code was generated can be a valuable indicator when diagnosing

intermittent problems.

An electronic service tool can retrieve and delete Logged codes. Any Logged diagnostic codes will

automatically be deleted if no additional occurrences are recorded in 100 hours.

When investigating logged diagnostic codes, keep in mind the following information.

Some diagnostic codes may be easily triggered and do not result in operator complaints. If the time the

code was logged does not relate to a complaint, there may be nothing to fix.

The most likely cause of an intermittent problem is a faulty connection or damaged wiring. Next likely is a

component failure (sensor or switch). Least likely is failure of the ECM itself.

Diagnostic codes that are logged repeatedly may indicate a problem that needs special investigation.

Continued

76

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

To diagnose a logged diagnostic code, refer to "Diagnostic code quick reference" on page 80. The code

number will direct you to the correct diagnostic test.

If the symptoms continue, use the appropriate procedure for diagnosing the symptoms that have been

experienced by the operator. Refer to "Diagnostic procedures without a diagnostic fault code" on page 36.

Note: Always clear logged diagnostic codes after investigating and correcting the problem which generated

the code.

Example: Output voltage from coolant temperature sensor. This diagram is for reference only and should not

be used to diagnose the coolant temperature sensor.

Sensor Diagnostic Generated

(Electronic Problem)

4.8 V

Logged Event, warning,

Engine is too hot,

derate, and shutdown occur

but there is not an

if applicable.

electronic problem

107 °C

4.2 V

(225 °F)

Warm Mode Temperature

Range 20 to 106 °C

(68 to 223 °F)

NORMAL

ENGINE

TEMPERA TURE

RANGE.

63 °C

2.8 V

(145 °F)

Cold Mode Temperature

Range -40 to 20 °C

(-40 to 68 °F)

0.2 V

Sensor Diagnostic Generated

(Electronic Problem)

A

HA0009

Logged events

The ECM can log events. Events refer to engine operating conditions such as low oil pressure or high coolant

temperature. Logged events do not indicate an electronic system problem, but may indicate an engine system

problem. The example diagram shown indicates the output voltage from a coolant temperature sensor and

how the ECM responds to that voltage.

Diagnostic Manual, TSD 3457E, Issue 2

77

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

4

2300 Series

Diagnostic terminology

Module Identifier (MID) - Two or three digit code which is assigned to each module or control system.

Module ID

Description

024

Engine Control Module (ECM)

Component Identifier (CID) - Two or three digit code which is assigned to each component or system.

Failure Mode Identifier (FMI) - Type of failure the component experienced (adopted from SAE standard

practice J1587 diagnostics).

Failure Mode Identifier

Description

Data valid, but above normal operational range

Data valid, but below normal operational range

Data erratic, intermittent, or incorrect

Voltage above normal or shorted high

Voltage below normal or open circuit

Current below normal or open circuit

Current above normal or grounded circuit

Mechanical system not responding correctly

Abnormal frequency, pulse width, or period

Abnormal update

00

01

02

03

04

05

06

07

08

09

10

Abnormal rate of change

11

Failure mode not identifiable

12

Faulty device or component

13

Uncalibrated device or component

Reserved for future assignment

14 - 31

Active Code - The MID, CID and FMI can be viewed on TIPSS-EST.

Logged Code - The diagnostic will be entered into the permanent memory (Diagnostic Log) when it becomes

Active. The number of occurrences will be saved in the good to bad counter in the permanent memory

(Diagnostic Log). First and last occurrence time (engine hours) will also be saved in the permanent memory

(Diagnostic Log). This information is then available for display on TIPSS-EST.

78

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

4

2300 Series

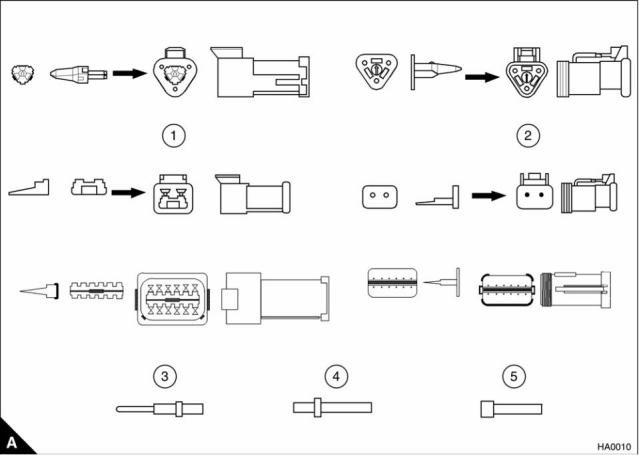

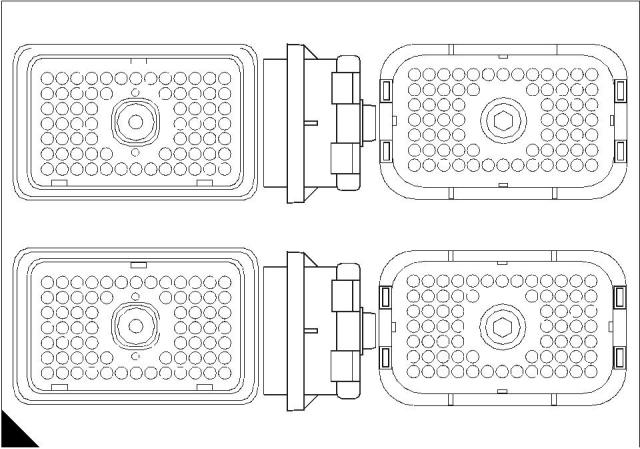

Connectors

Deutsch connectors - These connectors have a plastic housing. The pins and sockets are crimped onto the

electrical wires. The connector has a locking mechanism to hold the pins and sockets. These connectors are

repairable without cutting the wires.

1 Deutsch DT connector receptacles

2 Deutsch DT connector plugs

3 Deutsch and AMP pin

4 Deutsch and AMP socket

5 Deutsch and AMP sealing plug

Diagnostic Manual, TSD 3457E, Issue 2

79

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

4

2300 Series

Diagnostic code quick reference

CID-FMI

Diagnostic Code Description

Fault finding

1-11

Injector Cylinder #1 Fault

See Test 48 on page 138

See Test 48 on page 138

See Test 48 on page 138

See Test 48 on page 138

See Test 48 on page 138

See Test 48 on page 138

See Test 44 on page 112

See Test 44 on page 112

See Test 44 on page 112

See Test 41 on page 91

See Test 41 on page 91

See Test 41 on page 91

See Test 41 on page 91

See Test 40 on page 88

See Test 41 on page 91

See Test 41 on page 91

See Test 41 on page 91

See Test 41 on page 91

See Test 47 on page 134

See Test 47 on page 134

See Test 47 on page 134

See Test 45 on page 118

2-11

Injector Cylinder #2 Fault

3-11

Injector Cylinder #3 Fault

4-11

Injector Cylinder #4 Fault

5-11

Injector Cylinder #5 Fault

6-11

Injector Cylinder #6 Fault

41-03

8 Volt Sensor Power Supply Open/Short to B+

8 Volt Sensor Power Supply Short to ground

PWM Speed Control Abnormal

41-04

91-08

100-03

100-04

110-03

110-04

168-02

172-03

172-04

174-03

174-04

190-02

190-09

190-11, 12

248-09

Engine Oil Pressure Sensor Open/Short to B+

Engine Oil Pressure Sensor Short to ground

Engine Coolant Temp Sensor Open/Short to B+

Engine Coolant Temp Sensor Short to ground

Intermittent Battery Power to the ECM

Intake Manifold Temperature Sensor Open/Short to B+

Intake Manifold Temperature Sensor Short to ground

Fuel Temperature Sensor Open/Short to B+

Fuel Temperature Sensor Short to ground

Engine Speed Sensor Data Intermittent

Engine Speed Sensor Abnormal Update

Engine Speed Sensor Mechanical Fault

Perkins Data Link Communications Abnormal

See "System configuration

parameters" on page 12

253-02

254-12

Check Customer or System Parameters

ECM Fault

See "Programming a new ECM"

on page 24

261-13

262-03

262-04

Engine Timing Calibration Required

See Test 47 on page 134

See Test 43 on page 107

See Test 43 on page 107

5 Volt Sensor Power Supply Open/Short to B+

5 Volt Sensor Power Supply Short to ground

See "Programmable

parameters" on page 12

268-02

Check Programmable Parameters

273-03

273-04

274-03

274-04

281-05

281-06

282-03

282-04

285-03

285-04

286-03

286-04

323-05

323-06

324-05

324-06

342-02

342-11, 12

Turbo Outlet Pressure Sensor Open/Short to B+

Turbo Outlet Pressure Sensor Short to ground

Atmospheric Pressure Sensor Open/Short to B+

Atmospheric Pressure Sensor Short to ground

Action Alert Lamp Open Circuit

See Test 41 on page 91

See Test 41 on page 91

See Test 41 on page 91

See Test 41 on page 91

See Test 42 on page 101

See Test 42 on page 101

See Test 42 on page 101

See Test 42 on page 101

See Test 42 on page 101

See Test 42 on page 101

See Test 42 on page 101

See Test 42 on page 101

See Test 42 on page 101

See Test 42 on page 101

See Test 42 on page 101

See Test 42 on page 101

See Test 46 on page 126

See Test 46 on page 126

Action Alert lamp Short to ground

Engine Overspeed lamp Open/Short to B+

Engine Overspeed lamp Short to ground

Engine Coolant temperature lamp Open/Short to B+

Engine Coolant temperature lamp Short to ground

Engine Lubricating oil pressure lamp Open/Short to B+

Engine Lubricating oil pressure lamp Short to ground

Engine Shutdown Lamp Open Circuit

Engine Shutdown lamp Short to ground

Engine Warning Lamp Open Circuit

Engine Warning lamp Short to ground

Engine Speed Sensor No. 2 Data Intermittent

Engine Speed Sensor No. 2 Mechanical Fault

80

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

4

2300 Series

CID-FMI

443-05

Diagnostic Code Description

Fault finding

See Test 42 on page 101

See Test 42 on page 101

Contact Help Desk

Crank Terminate Relay Open Circuit

443-06

Crank Terminate Relay Short to ground

Service Tool Fault

799-12

1266-03

1266-04

1690-8

Diagnostic lamp Open/Short to B+

Diagnostic lamp Short to ground

Analogue Throttle Signal Abnormal

See Test 42 on page 101

See Test 42 on page 101

See Test 49 on page 146

Diagnostic Manual, TSD 3457E, Issue 2

81

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

4

2300 Series

Diagnostic tests

Inspecting electrical connectors

Test 39

Functional test

System operation

Many of the diagnostic tests in this manual will direct you to check a specific electrical connector.

Use this test to thoroughly inspect the connectors and determine if they are the cause of a fault. If a problem

is found in an electrical connector, repair the connector and check that the fault has been corrected.

Intermittent electrical faults are often caused by poor connections. Always check for an active diagnostic code

before breaking any connections and check again immediately after reconnecting the connector to see if the

fault has been corrected. Simply disconnecting and then reconnecting connectors can sometimes correct a

fault. If this occurs, likely causes are loose terminals, bent terminals, incorrectly crimped terminals or corrosion.

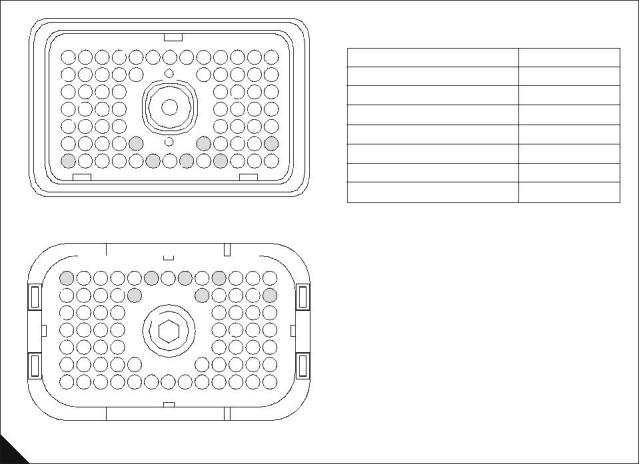

ECM terminal connections (general layout)

ECM AMP Connectors

17

2

3

4

5

6

8

9

10 11 12

13

23

31

39

47

57

70

13

12 11 10

9

8

7

6

5

4

3

2

1

14 15 16 17 18

24 25 26 27

>PEI<

19 20 21 22

28 29 30

23 22 21 20 19

31 30 29 28

39 38 37 36

47 46 45 44

18 17 16 15

27 26 25

14

24

32

40

48

32 33 34 35

36 37 38

35 34 33

40 41 42 43

44 45 46

43

51

42

50

41

49

48 49 50 51 52

53 54 55 56

57 56 55 54 53

52

58 59 60 61 62 63 64 65 66 67 68 69

70 69 68 67 66 65 64 63 62 61 60 59

58

ECM Side

Harness Side

Harness Connector P1

13

12 11 10

9

8

7

6

5

4

3

2

1

17

2

3

4

5

6

8

9

10 11 12

13

23

31

39

47

57

70

23 22 21 20 19

31 30 29 28

39 38 37 36

47 46 45 44

18 17 16 15

27 26 25

14

24

32

40

48

14 15 16 17 18

24 25 26 27

>PEI<

19 20 21 22

28 29 30

35 34 33

32 33 34 35

36 37 38

43

51

42

50

41

49

40 41 42 43

44 45 46

57 56 55 54 53

52

48 49 50 51 52

53 54 55 56

70 69 68 67 66 65 64 63 62 61 60 59

58

58 59 60 61 62 63 64 65 66 67 68 69

ECM Side

Harness Side

Harness Connector P2

A

HA0011

82

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

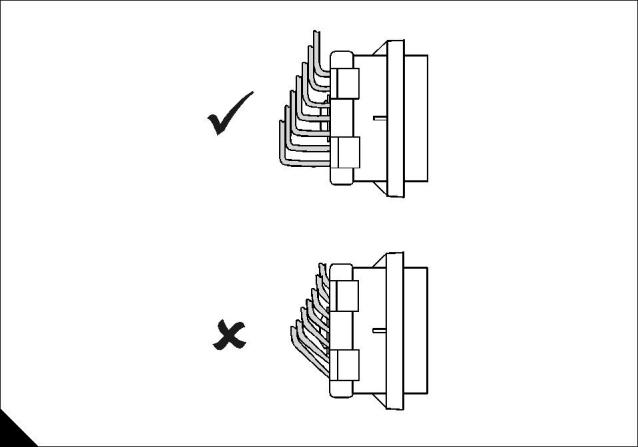

Functional test

Test 39 - Inspecting electrical connectors

Test step

Result

Action

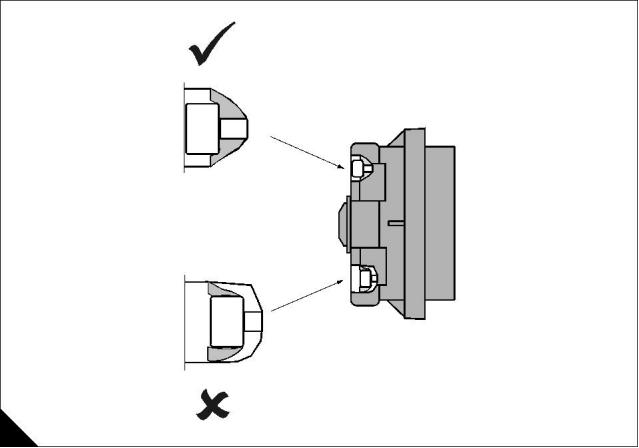

Step 1: Check the connector mating

Ensure that the plug and receptacle are correctly locked

together and cannot be pulled apart.

Go to step 2.

Repair or renew as

necessary.

Check that the connector locking tab is correctly locked and

returns to the fully locked position.

STOP.

Check that the connector and the locking mechanism is not

damaged.

Check that the connector interface is free from dirt and dust.

The connector will securely lock. The connector and locking

mechanism is without cracks or breaks.

Step 2: Check the ECM connector Allen screw

Ensure the Allen screw is correctly tightened to not more than

3,0 Nm (2.2 lb ft) 0,31 kgf m when mating the 70-terminal

“AMP” connector to the ECM.

Go to step 3.

Repair or renew as

necessary.

The ECM connector is secure and the ECM connector bolt is

correctly torqued.

STOP.

Step 3: Perform a 45 N (10 lb) pull test on each terminal and wire

Each terminal and connector should easily withstand 45 N

(10 lb) of pull and remain in the connector body. This test

checks if the wire is crimped correctly in the terminal and if the

terminal was correctly inserted into the connector.

Go to step 4.

Repair or renew as

necessary.

STOP.

Note: Terminals should always be crimped onto the wires using an

appropriate tool. Do not solder terminals.

Each terminal and connector easily withstands 45 N (10 lb) of

pull, and remains in the connector body.

Step 4: Observe the effect of the pull test on the electronic service tool

Warning! There is a strong electrical shock hazard while the

engine is turning. Do not touch wires associated with the injector

circuit while the engine is cranking or running.

Go to step 5.

Repair or renew as

necessary.

If there is an active diagnostic code pertaining to the circuit:

STOP.

Monitor the TIPSS-EST "Active Code" screen while pulling

on all harnesses and connectors that connect to the

component with the active diagnostic code. If the active

diagnostic code disappears while pulling on the harness,

there is a problem in the wiring or connector.

If there are no active diagnostic codes:

Monitor the TIPSS-EST "Status" screen for the component

while pulling on the harnesses. If the reading changes

erratically while pulling, there is a problem in the wiring or

connector.

If there are no active diagnostic codes and there is a sudden

intermittent engine speed changes or misfire:

Run the engine and listen for engine speed changes or

misfire while pulling on the wiring or connectors. If the

engine speed changes or cuts out while pulling on the

harness, there is a problem in the wiring or connector.

The problem appears to be external to the harnesses and

connectors. Tugging on the harnesses and connectors has no

affect on the active diagnostic code, component status, or

engine performance.

Diagnostic Manual, TSD 3457E, Issue 2

83

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

4

2300 Series

Test 39 - Inspecting electrical connectors (Continued)

Test step

Result

Action

Step 5: Check wires for damage to the insulation